Galvanized steel pipe for low pressure fluid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1、Structure of Galvanized steel pipe for low pressure fluid :

The surface of galvanized steel pipe welded steel pipe of hot dip galvanized layer or. Galvanized can increase the corrosion resistance of the steel tube, prolong service life. Galvanized pipe is widely used, in addition to water, gas, oil and other general low pressure fluid pipelines. It is also used in the petroleum industry, especially for offshore oil field of oil well pipe and oil pipe, chemical, coking equipment of oil heater, condensation cooler, coal run oil exchanger tube, and trestle pile, the mine tunnel support frame tube.

2、Main Features of Galvanized steel pipe for low pressure fluid :

• High manufacturing accuracy

• High strength

• Good visual effect

• Reasonable price

3、 Galvanized steel pipe for low pressure fluid Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1 - 33 mm |

Section Shape | Round |

Outer Diameter | 21 - 610mm |

Place of Origin | Tianjin, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:Q195 Q235 Q345 X42 X52

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface: galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Galvanized steel pipe for low pressure fluid :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

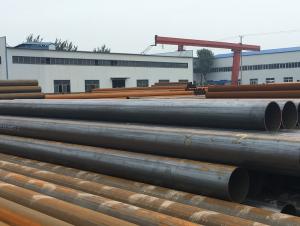

6、 Galvanized steel pipe for low pressure fluid Images:

- Q: How are steel pipes classified according to their wall thickness?

- Steel pipes are classified according to their wall thickness into three categories: schedule, standard, and extra strong.

- Q: How are steel pipes used in the construction of geothermal power plants?

- Steel pipes are used in the construction of geothermal power plants for various purposes. They are primarily used to transport and circulate the geothermal fluid, which carries the heat from the underground reservoir to the surface. These pipes are typically made of high-quality steel that can withstand the high temperatures and corrosive nature of the geothermal fluid. Additionally, steel pipes are used in the construction of injection wells, where cool water or other fluids are injected back into the reservoir to maintain pressure and sustain the heat extraction process. Overall, steel pipes play a crucial role in the efficient and reliable operation of geothermal power plants.

- Q: What is a valve and how is it used in steel pipes?

- A valve is a device used to control the flow of fluid or gas in a pipe system. In the context of steel pipes, valves are typically installed at specific points along the pipeline to regulate the flow, stop or start the flow, and control the pressure of the fluid or gas. These valves can be manually operated or automated, allowing for efficient control and maintenance of the steel pipe system.

- Q: Can steel pipes be used for underground heat exchange systems?

- Yes, steel pipes can be used for underground heat exchange systems. Steel is a durable and strong material that can withstand the pressure and environmental conditions typically found underground. It is resistant to corrosion and can handle high temperatures, making it suitable for transporting heat efficiently. Additionally, steel pipes are readily available and cost-effective compared to alternative materials, making them a popular choice for underground heat exchange systems. However, it is important to ensure proper insulation and protection of the steel pipes to prevent heat loss and damage from external factors such as moisture or soil movement.

- Q: What are the challenges faced in transporting steel pipes?

- Transporting steel pipes can pose several challenges. Firstly, steel pipes are heavy and bulky, making them difficult to handle and load onto transportation vehicles. Specialized equipment, such as cranes or forklifts, is often required to safely lift and maneuver the pipes. Secondly, steel pipes are susceptible to damage during transport. They can be easily scratched, dented, or bent if not properly secured. This necessitates careful packaging and securing techniques to prevent any deformation or damage during transit. Additionally, steel pipes are prone to corrosion, especially when exposed to moisture or harsh weather conditions. Therefore, protecting the pipes from moisture and maintaining proper storage conditions during transportation is crucial to prevent rusting and maintain their quality. Furthermore, the length of steel pipes can also present challenges. Depending on their size, some pipes may be too long to fit on standard transportation vehicles. This requires the use of specialized trailers or the pipes may need to be cut into smaller sections, which can add complexity and cost to the transport process. Lastly, the cost of transporting steel pipes can be high due to their weight and size. Freight charges can be expensive, especially for long-distance transportation. Thus, finding cost-effective transportation solutions while ensuring the safety and integrity of the pipes is a constant challenge in the industry.

- Q: How are steel pipes tested for pressure and leakage?

- Steel pipes are tested for pressure and leakage using a variety of methods to ensure their safety and reliability. One common method is hydrostatic testing, where the pipe is filled with water and subjected to a specific pressure for a specified duration. This test helps identify any weaknesses or leaks in the pipe by observing if there is any pressure drop or visible water leakage. The pressure is carefully measured and monitored during the test, and if the pipe successfully withstands the required pressure without any signs of leakage, it is considered to have passed the test. In addition to hydrostatic testing, other non-destructive testing methods may also be employed. These methods include ultrasonic testing, which uses high-frequency sound waves to detect any flaws or defects in the pipe material, and magnetic particle testing, which involves applying a magnetic field to the pipe and inspecting it for any magnetic particles that may indicate cracks or imperfections. Moreover, visual inspection is an essential step in testing steel pipes for pressure and leakage. Trained inspectors examine the exterior and interior surfaces of the pipe to check for any visible signs of damage, such as corrosion, cracks, or faulty welds. This visual inspection helps to identify potential weak points that could lead to leaks or failures under pressure. Overall, a combination of hydrostatic testing, non-destructive testing methods, and visual inspection is used to comprehensively evaluate steel pipes for pressure and leakage. These rigorous testing procedures ensure that the pipes meet the required standards and are safe for their intended applications.

- Q: What are the applications of steel pipes?

- Steel pipes are widely used in various industries and applications due to their exceptional strength, durability, and versatility. Some common applications of steel pipes include transportation of fluids and gases in oil and gas industry, water supply and drainage systems, structural support in construction projects, plumbing and heating systems, manufacturing of automobiles and machinery, and in the agricultural sector for irrigation and irrigation systems. Additionally, steel pipes are also used in the energy and power generation sector, chemical processing plants, and for underground and underwater installations.

- Q: Are steel pipes resistant to chemicals?

- Yes, steel pipes are generally resistant to chemicals. However, their resistance may vary depending on the specific type of chemical and the grade of steel used. Some chemicals may cause corrosion or degradation of the steel over time, so it is important to consider the compatibility of the pipe material with the intended chemicals before use.

- Q: How do steel pipes perform in high-temperature applications?

- Steel pipes perform well in high-temperature applications due to their excellent heat resistance and durability. They can withstand elevated temperatures without deforming or losing their structural integrity, making them ideal for transporting hot fluids or gases in industrial processes. Additionally, steel pipes have low thermal expansion, ensuring their dimensional stability under extreme heat conditions.

- Q: What are the different types of steel pipes?

- There are several different types of steel pipes, including seamless pipes, welded pipes, galvanized pipes, and stainless steel pipes.

Send your message to us

Galvanized steel pipe for low pressure fluid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords