Water Well Drill Pipe with API Spec 5DP Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Water Well Drill Pipe Description

We can supply all kinds of drill pipes that are consistent with API SPEC 5DP. Advanced drill pipe production lines can transfer the welding parameters to the best position to ensure the quality of welding zone; the heat treatment process with the feature of internal and external cooling at the same time can make a more reliable and stable mechanical character. Application of automatic weight, length measurement and automatic spray records can ensure products' traceability. Application of thickening and heating lines and 1250 tons of upsetting machine can ensure the thickening size meet the standard of API SPEC 5DR Using of CN furnace for whole pipe body heating and quenching, tempering machine's advanced heat treatment process can ensure the pipe's mechanical character. Tube hydraulic straightening machine ensures the straightness and coaxiality of pipe body.

SPEC: Φ73x9x(9.5/6.1)m Pipe body material: DZ40、DZ50、R780、G105

SPEC: Φ89x10x(9.5/6.1)m Tool joint material: 40Cr、45Mn2、35Crmo、4137H

2. Main Features of Water Well Drill Pipe

1) Advanced test for quality

2) MTC provided

3) API Standard

3. Water Well Drill Pipe Images

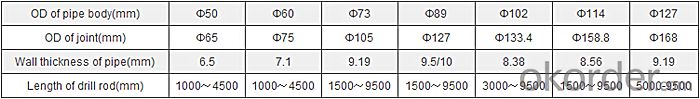

4. Water Well Drill Pipe Specification

5. FAQ of Water Well Drill Pipe

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in drill pipe products in China, mainly offering drill pipes including oil drill pipe, water well drill pipe, flat drill pipe, geological drill pipe and non-dig drill pipe.

Other than drill pipes we are also capable of supplying a wide variety of pipeline accessories, drill joints, steel pipe fittings, valves etc. consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: When can I use the PVC pipe and when to use the galvanized pipe?

- Galvanized pipes are generally used outside the drying environment or building blocks, and PVC is mainly used for pre embedding in walls or humid environments. If in the ceiling ceiling, below the roof, you need to use galvanized pipe, in the floor below, on the ground you need to use PVC.

- Q: Why can't stainless steel be put together with carbon steel tube?

- 1, the potential difference is: potential "stainless steel tube" and the negative potential "carbon steel" coupled "stainless steel", "a cathode carbon steel tube" is anode potentials of the two difference the greater the galvanic corrosion is bigger.2. An electronic passage formed by wire connection or direct contact. The carbon in the carbon steel tube loses its electrons to the stainless steel tube and the surface is absorbed by the etchant.3. Electrolyte: the contact area of two metals is covered or submerged by electrolyte. The iron in the carbon tube loses electrons to form ions into the solution, and the electrons on the surface of the stainless steel tubes are taken away by the corrosive agents in the electrolyte (such as oxygen in the air). Electrolytes become ionic channels.

- Q: What are the different types of steel pipe coatings for marine applications?

- There are several types of steel pipe coatings commonly used for marine applications, including epoxy coatings, polyurethane coatings, zinc coatings, and fusion-bonded epoxy coatings. Each coating offers different benefits such as corrosion resistance, abrasion resistance, and protection against marine organisms. The choice of coating depends on factors such as the specific marine environment, the level of corrosion protection required, and the budget.

- Q: What are the dimensions of a standard steel pipe?

- The dimensions of a standard steel pipe can vary depending on its intended use, but common dimensions include a nominal size (such as 1/2 inch, 1 inch, 2 inches, etc.) and a schedule number indicating its wall thickness (such as Schedule 40 or Schedule 80). The outside diameter of the pipe can range from small sizes of less than half an inch to large sizes of several feet. The length of a standard steel pipe is typically 21 feet, although shorter lengths are also available.

- Q: How are steel pipes used in firefighting systems?

- Steel pipes are used in firefighting systems to transport water or other fire-suppressing agents from a water source to the location of a fire. These pipes are durable and resistant to heat, making them suitable for carrying large volumes of water at high pressure to extinguish fires effectively. Additionally, steel pipes are often used for underground or overhead fire hydrant systems, sprinkler installations, and standpipe systems in buildings to ensure a reliable and efficient firefighting infrastructure.

- Q: What is the role of steel pipes in the transportation of water?

- The role of steel pipes in the transportation of water is to provide a durable and reliable infrastructure for the safe and efficient conveyance of water from its source to various destinations. Steel pipes are known for their strength, corrosion resistance, and ability to withstand high pressure, making them ideal for water transportation systems. These pipes ensure that water is delivered to homes, businesses, and other locations, while maintaining its quality and preventing leaks or contamination.

- Q: What are the different types of steel pipe coatings for corrosive environments?

- There are several types of steel pipe coatings used for corrosive environments, including epoxy coatings, polyethylene coatings, fusion bonded epoxy coatings, and zinc coatings. These coatings provide a protective barrier against corrosion and extend the lifespan of the steel pipes in harsh conditions.

- Q: What is the role of steel pipes in the construction of bridges?

- Steel pipes play a crucial role in the construction of bridges as they are used for various purposes such as supporting the weight of the bridge, providing structural integrity, and allowing for the flow of fluids or gases. Steel pipes are often used as support columns or piles in bridge foundations, providing stability and strength to the structure. They are also used for constructing bridge piers, trusses, and beams, ensuring the bridge can withstand heavy loads and forces. Additionally, steel pipes can be utilized for the transportation of water, gas, or other fluids across the bridge, making them essential for the overall functionality and longevity of the bridge.

- Q: What are the factors to consider when selecting steel pipes?

- When selecting steel pipes, there are several factors that need to be considered. These factors include the intended application, the required dimensions and specifications, the level of corrosion resistance needed, the operating temperature and pressure, the cost, and the availability of the specific type of steel pipe. It is important to carefully evaluate these factors to ensure that the selected steel pipes are suitable for the intended use and meet all the necessary requirements.

- Q: How are steel pipes insulated to prevent heat loss?

- Steel pipes are typically insulated to prevent heat loss by wrapping them with insulation materials such as mineral wool, fiberglass, or foam. These insulation materials provide a barrier that traps heat within the pipes, preventing it from being lost to the surrounding environment. Additionally, pipes may also be covered with an outer protective layer, such as aluminum or PVC, to further enhance insulation and protect against external elements.

Send your message to us

Water Well Drill Pipe with API Spec 5DP Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords