HDPE High-Performance Non-Woven Geotextile Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Non-woven geotextile fabrics are primarily used for projects where highly permeable

separators are required. This includes applications that must allow water to flow while

preventing soil erosion or soil loss.

Applications:We offer a wide range of Non Woven Geotextile Fabrics used while making

Highways and Road Construction. Non Woven Geotextile fabrics are also known as civil

engineering fabrics, erosion control cloth, filter fabrics and support membranes.

RP make Non Woven Geotextile fabrics have their project, structure, or system based on

various geo technical materials such as soils, rock, earth etc. Non Woven Geotextile

fabrics are either used to restrict or allow passage of Water in Slopes and Road

construction, as desired.

The Range of Needle punch Non Woven Geotextile fabrics offered by us are as follows:

Reinforcement

Drainage

Separation

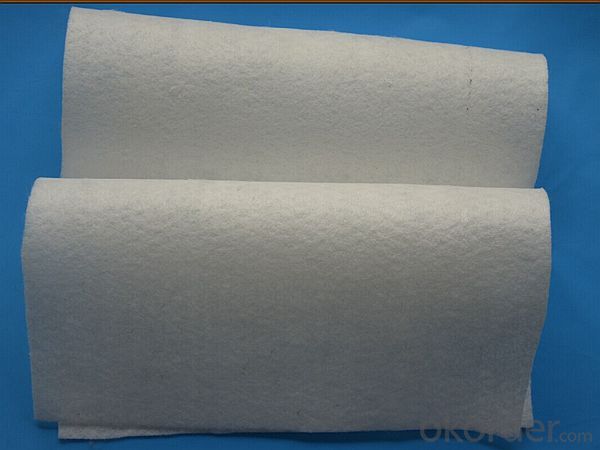

Non Woven Geotextile Product Show:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Can geotextiles be used in the construction of reservoirs?

- Yes, geotextiles can be used in the construction of reservoirs. Geotextiles are commonly used in civil engineering projects, including reservoir construction, to provide filtration, separation, and reinforcement. They can be used to prevent soil erosion, stabilize slopes, and enhance the overall performance and longevity of reservoir structures.

- Q: How do geotextiles help with soil confinement in erosion control bags?

- Geotextiles play a crucial role in soil confinement within erosion control bags by acting as a barrier that prevents the soil from escaping while allowing water to pass through. They provide structural stability to the bag, preventing it from collapsing or shifting, thereby maintaining the shape and effectiveness of the erosion control structure. Additionally, geotextiles help in distributing the load evenly across the bag, minimizing stress on the soil and enhancing its ability to resist erosion.

- Q: Geotextile what is the law?

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. The American Society of Agricultural Engineers defines geotextiles as geotextiles or geosynthetics that exist between soils and pipelines, gages, or retaining walls that enhance water movement and impede soil movement. ASTM 4439 standard geotextile is defined as: a purely permeable geosynthetics to form textiles. Is used in soil, rock, soil or other geotechnical engineering related materials and acts as a component of a human-made project. Geotextile is a new type of building materials, raw materials are polyester, polypropylene, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. General engineering is mainly used non-woven geotextile. Geotextile with filter, filter, isolation, reinforcement, protection, sealing and other functions.

- Q: Woven geotextile is not considered a spinning geotextile

- Woven geotextile is made of textile technology is a spinning geotextile.

- Q: How do geotextiles improve the performance of geocomposites?

- Geotextiles improve the performance of geocomposites by providing reinforcement, filtration, and separation functions. They enhance the strength and stability of the composite by distributing loads and reducing soil movement. Geotextiles also prevent the mixing of different materials within the composite, ensuring efficient drainage and filtration of liquids while maintaining the integrity of the structure. Additionally, they help to control erosion and provide long-term durability, ultimately enhancing the overall performance and effectiveness of geocomposites.

- Q: How do geotextiles affect soil nutrient availability?

- Geotextiles can have both positive and negative effects on soil nutrient availability. On one hand, geotextiles can help retain nutrients in the soil by preventing their leaching and runoff, thus promoting their availability for plant uptake. On the other hand, if geotextiles are impermeable to water and air, they can hinder nutrient exchange processes and microbial activity, ultimately reducing nutrient availability in the soil. Therefore, the impact of geotextiles on soil nutrient availability depends on their design and application.

- Q: Geotextile seepage seams how to deal with

- First geotextile is not waterproof, you say is a composite geomembrane, seams with a welding machine welding, can also use ks hot melt welding. Huazhi engineering materials manufacturers to answer your questions

- Q: What are the specifications for geotextiles in erosion control projects?

- The specifications for geotextiles in erosion control projects typically include factors such as tensile strength, permeability, thickness, and specific weight. They should be able to withstand the forces of soil erosion, have a suitable permeability to allow water to pass through while retaining the soil, and be of a thickness and weight that can effectively support the intended application.

- Q: What are the geotextiles?

- Slope protection is best to use geomembrane above cover geotextile, or directly composite geomembrane can be, you can consult me by user

- Q: What are the different testing methods for geotextiles?

- Some of the different testing methods for geotextiles include tensile strength testing, puncture resistance testing, tear strength testing, burst strength testing, and water flow testing. These tests help evaluate the performance and durability of geotextiles in various applications.

Send your message to us

HDPE High-Performance Non-Woven Geotextile Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords