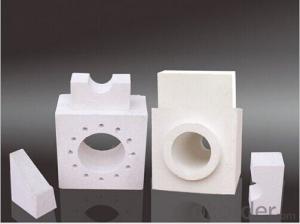

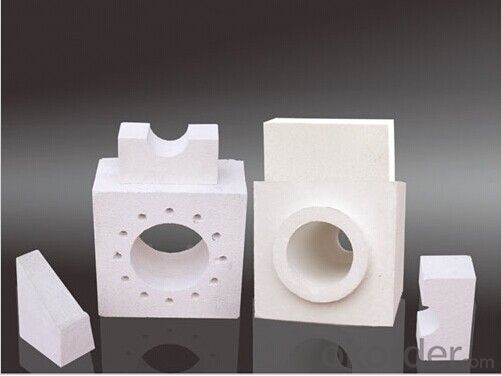

High-Aluminum Low-Iron Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

High aluminum refractory brick belongs to gender refractory materials with its thermal stability.

Feature:

1.bricks are made from high quality bauxite

2.dry pressed

3.burned under tunnel kiln

4.accurate dimension

5.high strength

Product specification: Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the mostly used in the key positions.Molding method: it has down draft kiln and tunnel kiln and the general sintering temperature is 1360-1480 degrees. It is a kind of aluminosilicate refractory product which aluminum oxide (Al2O3) content is higher than 48%.

Item | Properties | |||||

LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

Al2O3 ,% | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

Refractoriness °C | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

Bulk density,g/cm3 | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

Softening temperature under load | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

Permanent linear change,% | 1500°CX2H | +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 |

|

1450°CX2H |

|

|

|

| +0.1 -0.4 | |

Apparent porosity,% | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

Cold Crushing strength Mpa | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

Application | All industrial furnace | |||||

- Q: Can insulating fire bricks be used in tundish linings?

- Yes, insulating fire bricks can be used in tundish linings. Insulating fire bricks are made from lightweight refractory materials that have excellent insulating properties. Tundish linings are typically exposed to high temperatures and thermal shocks, which can lead to rapid wear and tear. By using insulating fire bricks, the tundish lining can be protected from excessive heat and thermal stresses. These bricks have low thermal conductivity, which helps to minimize heat loss and maintain a stable temperature inside the tundish. Additionally, insulating fire bricks have good mechanical strength and can withstand the mechanical stresses typically experienced in tundish operations. Overall, using insulating fire bricks in tundish linings can help to improve thermal efficiency, reduce energy consumption, and extend the service life of the tundish.

- Q: Can insulating fire bricks be used in the construction of brick ovens?

- Yes, insulating fire bricks can be used in the construction of brick ovens. These bricks have high-temperature resistance and excellent insulation properties, making them suitable for retaining heat and preventing heat loss in a brick oven.

- Q: Are insulating fire bricks suitable for the insulation of chimneys?

- Yes, insulating fire bricks are suitable for the insulation of chimneys. Insulating fire bricks are specially designed to withstand high temperatures and provide effective insulation, making them ideal for use in chimneys. They have a high thermal conductivity, which means they can retain heat and prevent it from escaping, thereby improving the efficiency of the chimney. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is particularly important in chimneys, where the temperature can fluctuate dramatically during the combustion process. Overall, insulating fire bricks are a reliable choice for chimney insulation, as they offer excellent heat retention and durability.

- Q: Can insulating fire bricks be used in high-temperature insulation for aerospace applications?

- Yes, insulating fire bricks can be used in high-temperature insulation for aerospace applications. These bricks are designed to withstand extremely high temperatures and provide excellent insulation properties, making them suitable for use in aerospace applications where thermal protection is crucial.

- Q: Are insulating fire bricks resistant to weathering?

- Insulating fire bricks have remarkable resistance to weathering. Crafted from top-notch refractory materials, these bricks are engineered to endure severe temperatures and rugged weather conditions. They are designed to exhibit exceptional resistance against thermal shock, erosion, and corrosion induced by exposure to diverse weather elements like rain, snow, wind, and sunlight. Moreover, insulating fire bricks possess resistance to chemical assaults, establishing their durability and suitability for long-term outdoor applications. In summary, the formidable composition and weathering resilience of insulating fire bricks render them a dependable option for insulation and construction needs in outdoor settings.

- Q: Can insulating fire bricks be used in the construction of thermal oxidizers?

- Yes, insulating fire bricks can be used in the construction of thermal oxidizers. Insulating fire bricks have excellent thermal insulation properties, which make them ideal for applications where high temperatures need to be contained within a specific area. Thermal oxidizers are used to combust volatile organic compounds (VOCs) at high temperatures, and the use of insulating fire bricks can help maintain the required temperature within the combustion chamber while minimizing heat loss to the surroundings. Additionally, insulating fire bricks are lightweight, durable, and have good resistance to thermal shock, which further contributes to their suitability for use in thermal oxidizers.

- Q: Do insulating fire bricks emit any harmful gases when heated?

- No, insulating fire bricks do not emit any harmful gases when heated. They are specifically designed to have excellent thermal insulation properties without releasing any harmful emissions.

- Q: Can insulating fire bricks be used in refractory coatings?

- Yes, insulating fire bricks can be used in refractory coatings. They provide excellent thermal insulation properties and can help in maintaining high temperatures while minimizing heat loss.

- Q: Can insulating fire bricks be used as a refractory material?

- Yes, insulating fire bricks can be used as a refractory material. Insulating fire bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for use in various refractory applications such as furnaces, kilns, and insulation linings.

- Q: What is the thermal expansion of insulating fire bricks?

- The thermal expansion of insulating fire bricks is relatively low, typically around 0.5% to 1%.

Send your message to us

High-Aluminum Low-Iron Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords