Insulating Fire Brick IFB Straights for Ceramics Industries

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What it the Insulating Fire Brick?

Insulating fire bricks (IFBs) are called soft bricks comparing to hard bricks or Fireclay bricks and they are light in weight. Insulating fire brick can be easily cut by handheld hack saw or other hand tools like chisel. Insulating firebricks have high porous rate and have excellent insulating properties.

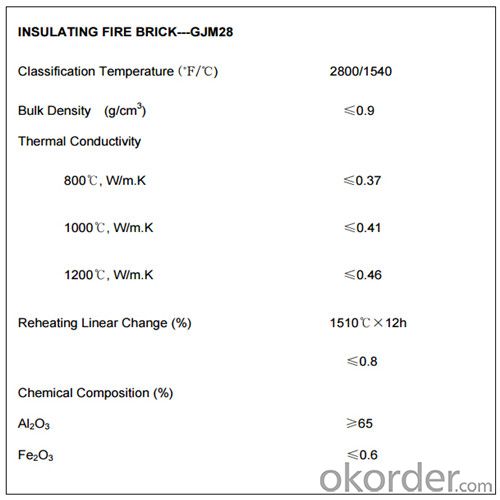

Technical Data of Insulating Fire Brick

What are the excellent features of Insulating Fire Brick?

High heat resistance and durability

Excellent insulating properties

Excellent resistance to thermal shock

Low thermal conductivity

Low heat storage

Excellent construction/compressive strength

Particularly suited to highest temperature applications above 1600°C or 2800°F

Structural integrity capable of dealing with erosive and abrasive environments

Low impurity

Precise dimensions

Image of Insulating Fire Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q: Do insulating fire bricks have a high fireproof rating?

- Insulating fire bricks indeed have a high fireproof rating. These bricks are specifically designed to withstand extremely high temperatures and provide excellent insulation against heat transfer. They are made from special refractory materials that have low thermal conductivity, which helps in retaining heat and preventing it from escaping the system. Insulating fire bricks can withstand temperatures ranging from 2300°F to 3100°F (1260°C to 1700°C), making them ideal for use in furnaces, kilns, fireplaces, and other high-temperature applications. Their high fireproof rating ensures that they can effectively protect structures and equipment from the intense heat and flames, allowing for safe and efficient operation in various industries.

- Q: How do insulating fire bricks compare to other insulation materials?

- Insulating fire bricks, as insulation materials, possess several advantages over other options. Firstly, they exhibit exceptional thermal properties, enabling the efficient prevention of heat transfer. Their low thermal conductivity effectively insulates against high temperatures, making them ideal for heat retention in furnaces, kilns, and fireplaces. In comparison to fiberglass or mineral wool, insulating fire bricks prove significantly more durable and long-lasting. They withstand extreme temperatures without compromising their insulation or structural integrity. Consequently, their longevity makes them a cost-effective selection, necessitating less frequent replacement. Another benefit of insulating fire bricks lies in their resistance to chemical attack and wear. They exhibit resilience against acids, alkalis, and other corrosive substances, rendering them suitable for applications involving harsh chemicals or environments. Moreover, their high compressive strength allows them to bear heavy loads without cracking or breaking. This quality makes them suitable for structural applications that require weight-bearing capacity. Installation-wise, insulating fire bricks are easily workable. They can be cut, shaped, and installed using basic tools, offering customization and flexibility for diverse applications. Their lightweight nature simplifies the installation process and reduces overall structural weight. In conclusion, insulating fire bricks surpass other insulation materials in terms of insulation properties, durability, chemical resistance, and ease of installation. Their ability to endure high temperatures, resist wear and tear, and provide long-lasting insulation make them an exceptional choice for various industrial and domestic settings.

- Q: Can insulating fire bricks be used in the construction of pottery molds?

- Yes, insulating fire bricks can be used in the construction of pottery molds. Insulating fire bricks are made from lightweight refractory materials that have excellent heat insulation properties. These bricks are specifically designed for applications that require high temperatures, such as pottery kilns. When constructing pottery molds, it is important to have materials that can withstand the intense heat of the kiln. Insulating fire bricks can withstand temperatures up to 3000°F (1650°C), making them suitable for pottery mold construction. They provide insulation to prevent heat loss and maintain consistent temperatures inside the kiln, which is essential for achieving the desired firing results. Furthermore, insulating fire bricks can be easily shaped and cut to fit the desired mold design. They are also lightweight, which makes them easier to handle during the mold construction process. Additionally, the insulating properties of these bricks help to reduce energy consumption by preventing excessive heat loss, making them cost-effective in the long run. Overall, insulating fire bricks are a suitable choice for constructing pottery molds due to their ability to withstand high temperatures, provide insulation, and be easily shaped to fit specific designs.

- Q: Do insulating fire bricks require a specific curing or drying process before use?

- Yes, insulating fire bricks typically require a specific curing or drying process before use. This involves gradually heating the bricks to remove any moisture or volatile materials present, which helps to prevent cracking or damage during subsequent use. The exact curing or drying process may vary depending on the specific type and manufacturer of the insulating fire bricks.

- Q: Are insulating fire bricks resistant to warping?

- Insulating fire bricks are known for their resistance to warping. They are specifically designed to withstand high temperatures and thermal shocks, preventing any potential warping. These bricks are crafted using lightweight materials like clay, silica, and alumina, which are combined with additives to enhance their insulation capabilities. Moreover, these additives not only contribute to the brick's insulation, but also aid in its resistance against warping. Furthermore, insulating fire bricks undergo a meticulous manufacturing process that ensures dimensional stability and reduces the risk of warping. It is worth mentioning, however, that prolonged and extreme exposure to high temperatures may still result in some warping, albeit to a lesser extent than other brick types.

- Q: Can insulating fire bricks be used for fireplace construction?

- Indeed, insulating fire bricks are suitable for constructing fireplaces. These bricks are specifically engineered to endure extreme temperatures while offering superb insulation, rendering them perfect for lining fireplaces. They aid in retaining heat, improving fireplace efficiency, and preventing heat dissipation. Furthermore, insulating fire bricks possess a lightweight quality, facilitating easier handling and installation. Ultimately, opting for insulating fire bricks in fireplace construction is a pragmatic decision that can enhance fireplace performance and energy efficiency.

- Q: Can insulating fire bricks be used in the construction of industrial furnaces?

- Indeed, the utilization of insulating fire bricks is viable in the creation of industrial furnaces. These bricks are specifically engineered to endure elevated temperatures and thermal shocks, rendering them suitable for deployment in furnaces operating at exceedingly high levels of heat. Their thermal conductivity is notably low, thereby reducing heat dissipation and enhancing the energy efficiency of the furnace. Moreover, these fire bricks exhibit a lightweight composition and are effortlessly maneuverable, thereby proving to be convenient for construction endeavors. In summary, the superb insulation capabilities and heat-resistant attributes of insulating fire bricks position them as an optimal selection for the construction of industrial furnaces.

- Q: Are insulating fire bricks resistant to flame spread?

- Insulating fire bricks exhibit exceptional resistance against flame propagation. Crafted with utmost precision, these bricks are tailored to endure extreme temperatures while effectively trapping and insulating heat. Constructed from refractory materials with minimal thermal conductivity, they possess remarkable capabilities in impeding heat transfer and thwarting the spread of flames. Widely employed in kilns, furnaces, and fireplaces, where maintaining and managing high temperatures is of paramount importance, these bricks' flame-resistant properties render them an unwavering and secure choice for such environments.

- Q: Are insulating fire bricks suitable for use in the construction of smelters?

- Insulating fire bricks are indeed appropriate for the construction of smelters. These bricks are specifically engineered to endure high temperatures and offer exceptional insulation qualities, thus rendering them a perfect choice for smelting purposes. Their thermal conductivity is low, enabling efficient heat retention and minimized energy wastage throughout the smelting procedure. Moreover, insulating fire bricks exhibit resistance to thermal shock, a vital feature in smelting operations characterized by abrupt temperature fluctuations. Thus, owing to their superior capacity to withstand heat and insulate, insulating fire bricks present a dependable option for smelter construction.

- Q: What is the thermal insulation performance of aerated bricks?

- Dongfeng steam free insulation performance of aerated brick brick production equipment; because the thermal conductivity of foamed concrete block is only 0.21W/M.K, which is 4 times the heat preservation effect of clay brick, cement brick 3 times, so it can improve the living comfort, hot summer and cold winter, can be greatly reduced the running time of the air conditioner,

Send your message to us

Insulating Fire Brick IFB Straights for Ceramics Industries

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords