High Alumina Brick for Electric Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Bricks for Electric Furnace

Composite of High Alumina Bricks

High Alumina Bricks are classified according to alumina content ranging from 48% to 90%.

Main Features of High Alumina Bricks

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Application of High Alumina Bricks

commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

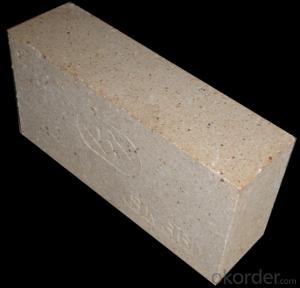

High Alumina Bricks Images

Specification of High Alumina Bricks

HIGH ALUMINA BRICK---ALP85 | |

Apparent Porosity (%) | ≤18 |

Bulk Density (g/cm3) | ≥2.85 |

Cold Crushing Strength (Mpa) | ≥80 |

Modulus Of Rupture (Mpa) | ≥20 |

Refractoriness Under Load (0.2 Mpa)(℃) | 1450 |

Permanent Linear Change (%) | 1500℃×3h -0.5 ~+0.5 |

Chemical Composition (%) |

|

Al2O3 | ≥82 |

Fe2O3 | ≤1.5 |

P2O5 | ≤3 |

FAQ of High Alumina Bricks

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report, also we could apply other necessary certification.

- Q: What is the standard size of high alumina brick?

- Standard brick: 230 x 115 x 65; four points: 230 x 115 x 40; three points: 230 x 115 x 30; 150 x 120: Brick gable. Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms.

- Q: How are the high alumina bricks fired?

- Generally, the high alumina bauxite is added with a small amount of clay. After being ground, the gas is injected and shaped in the form of slurry by the way of gas attack or foam, and it is burnt at 1300~1500 DEG C. Sometimes industrial alumina can be used to replace part of bauxite clinker. Used for lining and thermal insulation of masonry kilns, as well as for areas where there is no high temperature, high melting material erosion and erosion effects. When touching the flame directly, the touch temperature shall not be higher than 1350 degrees.

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- Refractory powders are not rich in free silica in varying degrees

- Q: Which is better, the soft core or the hard core?

- When the current through the wire, it will produce a magnetic field in the vertical plane space of the wire, if there is a current two wire close by in the same direction, because they produce a magnetic field in the direction is opposite, it will produce a repulsive force is due to the magnetic field force. They will mutually inhibit current intensity of the other party, caused by the reduction of current in the wire, this inhibition of each current intensity, we called wire inductance. When the AC current line frequency is high, the inductance is stronger.

- Q: The difference between ordinary and diatomite brick refractory brick

- To say the difference, the material is the biggest difference. There are diatomite brick density, compressive strength of small brick kiln belongs to the outer thermal insulation, and heavy refractory brick kilns for multi village in direct contact with the flame, high temperature resistance, good compressive strength, but no insulation. Hope to help you.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Forming high alumina brick will be tested on some professional equipment, it is suggested that you can go to the professional testing department to know about it!

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- The expansion of high alumina brick is not only related to temperature, but also related to its material composition. The refractory temperature of high alumina brick is above 1770 centigrade. The temperature of 800 DEG C has little influence on the expansion of high alumina brick.

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- Generally, the thermal shock resistance of high alumina brick products is worse than that of clay brick products

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- First of all, there is a difference in the material, one is clay, and one is high aluminum.Also known as clay brick brick, is a man-made small bulk building, clay brick clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting, solid and hollow.

- Q: What are the categories of bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels.

Send your message to us

High Alumina Brick for Electric Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords