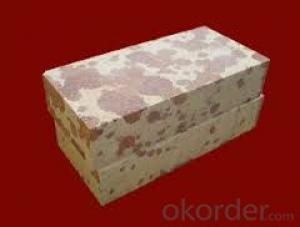

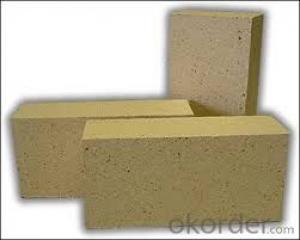

High Alumina Fireclay Refractory Bricks for Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Fireclay refractory bricks for furnace are produced with selected bauxite chamotte by advanced process and strict quality control. The main mineral components are corundum and mullite phases. It features excellent high temperature mechanics and chemical corrosion resistance.

Features

1.Resisting high temperature

2.Great bulk density

3.Low iron content

4.Good eroding resistance

Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients’ quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Specifications:

Ordinary High alumina brick

Item | HA60 | HA70 | HA75 | HA80 |

AL2O3(%) | ≥60 | ≥70 | ≥75 | ≥75-80 |

SIO2(%) | 32 | 22 | 20 | ≥18 |

Fe2O3(%) | ≤1.8 | ≤1.8 | ≤1.8 | ≤1.8 |

Refractoriness °C | 1790 | >1800 | >1825 | ≥1850 |

Bulk density,g/cm3 | 2.4 | 2.45-2.5 | 2.5 | 2.55-2.6 |

Softening temperature under load | ≥1470 | ≥1520 | ≥1530 | ≥1550 |

Apparent porosity,% | 22 | <21 | <21 | <20 |

Cold Crushing strength Mpa | ≥45 | ≥50 | ≥54 | ≥60 |

Phosphate bonded high alumina bricks

Item | LAP75 | LAP77 | LAP85 |

AL2O3 % | ≥75 | ≥77 | ≥80-85 |

Fe2O3 % | ≤3.0 | ≤3.0 | ≤1.8 |

Ca0 % | ≤0.6 | ≤0.6 | ≤0.6 |

Refractoriness °C | ≥1800 | ≥1800 | ≥1850 |

Bulk density g/cm3 | ≥2.65 | ≥2.70 | ≥2.80 |

Cold crushing strength MPa | ≥60 | ≥64 | ≥110 |

Refractoriness under load 0.2MPa °C | ≥1350 | ≥1300 | ≥1350 |

Application | Used for high temperature parts lining of cement rotary kiln | Used for Badly worn parts of cement rotary kiln | |

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: What are the requirements for Rubble backfill height?

- Backfill should be filled with large stones, big face, small face upward, the decoration is stable, and then use small stones leveling, the gap between the stones can be swept into the slag, gravel, so that the gap filled.

- Q: What is the density of a super high alumina brick and what is the price?

- Of course, the transaction price, please choose refractory brick manufacturer is better.

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- If the condition, the user heat-resistant steel welding grip nails, expansion joints can not be too big.. Also to use high temperature aluminum brick, high temperature resistance, but also to extend its use cycle.

- Q: Can high alumina brick resist carburizing?

- Louzhu can use heavy impervious material, it is neither high alumina brick nor mullite, this product can resist seepage and have good compressive strength

- Q: What are the requirements for refractory materials in heat treatment furnace?

- The structural strength of high temperature is evaluated by loading softening point. Load softening point is that under certain pressure (2 kg/ cm 2 = 0.2MPa) under the condition of heating rate to heating, measured the sample deformation (deformation for the original sample 0.6%) temperature. This temperature is called the softening point of the refractory. Sample size is Phi 36 x 50mm.

- Q: What kind of material is the general metal case?

- Generally speaking, the outer surface of the case is usually made of a steel plate of more than 1 millimeters. The thickness and the material of the steel plate are directly related to the rigidity of the case, as well as the capability of sound insulation and anti electromagnetic radiation. The regular manufacturers of the chassis plate thickness not less than 1.3mm, but there are also some small manufacturers with a thickness of only about 1mm steel, we do not need the ruler to the amount, as long as you put him up, the more weight in the same volume of the chassis is better, in addition, we can also use the finger bomb case shell. If you can hear the crisp percussion sound proof of the casing plate is thin and brittle, if you hear is relatively dull and heavy sound that the chassis material must be good, good general steel plate coated with a layer of thin zinc (bright part), so it can withstand high strength, impact resistance, hardness high elasticity. The frame parts of the chassis are made of high quality materials with high hardness. They are bent into angle shapes or strip shapes. We can shake the chassis frame of the case by hand. Good chassis should be relatively stable, and inferior chassis light is easy to shake. When choosing, we should also pay attention to the outer edge of the case and the edge of the inner bracket. Whether the incision is smooth or not, a good case will not appear in the case of rough edges, sharp edges, burrs and so on. While the poor case appears above phenomenon, often appear when installing the blood splattered". Generally speaking, the chassis must go through the corresponding grinding process before leaving the factory. The edge of the flat plate some burr, edges and corners are rounded, the corresponding fold some corner. When you install such a case, you don't worry about cuts, and some rough, poorly built cabinets tend to scratch your hands.

- Q: Use of high alumina refractory bricks?

- High alumina brick refractory than clay refractory bricks and brick refractory degree are higher, up to 1750~1790 DEG C, which belongs to high-grade refractory materials.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- The gas will directly lead the dome combustion, in order to ensure good mixing, complete combustion of gas and air in a short time, the combustion capacity of short flame or flameless combustion burner, commonly used for semi jet short flame burner.

Send your message to us

High Alumina Fireclay Refractory Bricks for Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords