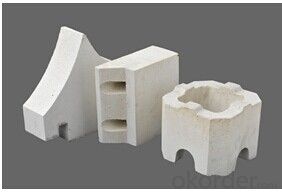

High Alumina Sillimanite Fire Brick for Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Resistance to corrosion and erosion;

2.Least contamination for molten glass;

3.Improve the productivityaa

4.Long life

Features:

The sillimanite brick is made of sillimanite minerals.After high temperature calcination,it become mullite and

dissociate silicon dioxide.Generally use high-temperature firing method and slurry casting method to produce.

1.Good thermal stability.

2.Strong resistance to chemical attack.

3.It is the first choice of stable material for glass forming.

Applications:

1.Widely used in glass furnace,such as regenerator arch.

2.Mainly used in the blast furnace.

3.

Sillimanite brick physiochemical index:

Item | Properties | ||||||

Sillimanite | Andalusite | Cordierite and mullite | Pouring sillimanite | ||||

LS-65 | L-60 | H-60 | HS-55 | SPCD-50 | SPCD-60 | CS-58 | |

AL2O3(%) | 65 | 60 | 60 | 55 | 50 | 60 | 58 |

Fe2O3(%) |

|

|

|

|

|

| 0.8 |

Refractoriness,°C | 1790 | 1790 | 1790 | 1770 | 1770 | 1790 | 1790 |

Apparent porosity % | 22 | 22 | 22 | 22 | 24 | 24 | 26 |

Cold Crushing strength MPa | 50 | 50 | 40 | 40 | 40 | 50 | 50 |

Bulk density,g/cm3 | 2.2 | 2.2 | 2.5-2.7 | 2.5-2.7 | 2.4 | 2.4 | 2.2 |

Softening temperature under load,KD°C≥ | 1550 | 1500 | 1500 | 1450 | 1450 | 1500 | 1450 |

Permanent linear change,%(°C×h) | ±0.2 | ±0.2 | ±0.2 | ±0.2 | (1000°C)≤±0.5% | (1000°C)≤±0.5% | 1400°C×2h +0.1 -0.3 |

Application | Used for temperature change severe industrial furnace and thermal lining equipment | All sorts of kiln burner brick and ceramic kiln brick | All industrial furnace | ||||

- Q: What is fireproof concrete?

- According to the different properties of fire resisting and heat resisting concrete, they can be divided into silicate, aluminate, phosphate, sulfate, chloride, sol and organic substance, fireproof and heat-resisting concrete, etc.. The following are mainly used silicate, aluminate, phosphate, sulfate fire, heat-resistant concrete.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: The difference between aluminium refractory and magnesia refractory

- Magnesia refractory belongs to alkaline refractory materials refers to refractory products such as magnesia magnesia brick magnesium iron spinel magnesium aluminum spinel magnesia ramming materials and other products of raw materials is the main crystal phase is periclase magnesia products

- Q: What are the common thermal insulation materials for thermal conductivity?

- The vacuum heat insulation plate is a kind of high efficiency thermal insulation board made of inorganic fiber core material and high resistance gas composite film. It is made of vacuum encapsulation technology and covered with special interface mortar.

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- If the condition, the user heat-resistant steel welding grip nails, expansion joints can not be too big.. Also to use high temperature aluminum brick, high temperature resistance, but also to extend its use cycle.

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- Low creep and high alumina brick is based on the theory of "three stones". The combination of bauxite and clay as the main raw material, adding kyanite, andalusite and sillimanite, commonly known as the "three stone" control, physicochemical index and size composition, using alumina mullite corundum + + raw materials such as technical scheme. In the production process, first to detect and control indexes of raw materials, crushing, grinding, sieving process, according to the distribution ratio of ingredients, the size and moisture control of mud mixing after to meet the requirements of forming and molding machine, the use of qualified abrasives, blow molding control number, size and flash at the same time, the detection efficiency of semi-finished products and meet the requirements. Production process: high temperature calcination of high-grade alumina, adding small creep rate of high temperature materials, by high-pressure molding and high temperature firing. It has the characteristics of high strength, low creep rate and high use temperature. Widely used in high temperature furnace, hot air furnace hearth lining, brick and so on.

- Q: The difference between ordinary and diatomite brick refractory brick

- Insulation products made from diatomaceous brick and porous diatomite. The main raw material is natural porous diatomite, and then a small amount of clay and fuel are added. The volume density of diatomite brick was 0.7g/cm3, compressive strength at room temperature is 1 ~ 2MPa, the coefficient of thermal conductivity at 400 C for 0.13 ~ 0.20W/ (M - K), the apparent porosity is greater than 70%, the coefficient of thermal expansion (1280 degrees) 0.9 x 10 - 6 DEG -1, refractoriness is greater than 1250 DEG C. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius.

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina brick, also called high alumina insulation brick. Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. Volume density 0.4 - 1.35g/cm3. Porosity 66% - 73%, compressive strength 1 - 8MPa. Better thermal shock resistance. Usually, a high alumina clinker is added with a small amount of clay. After grinding, it is poured and shaped in the form of slurry by gas generation or foam method, and it is fired at 1300 - 1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Prolong the sintering time and adjust the aluminum content of the high alumina brick.

Send your message to us

High Alumina Sillimanite Fire Brick for Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords