High Alumina Brick UAL55 - High Alumina Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

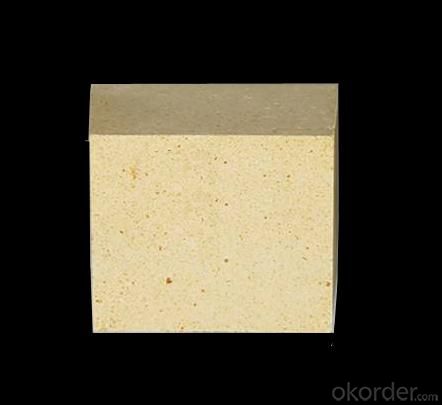

General Information of High Alumina Brick UAL55

Our company’s High Alumina Bricks UAL55 are the final result of blending excellent high-purity fused alumina as the main raw material with cutting-edge technology, adding superfine powder, after mixing, drying, forming, in the high temperature shuttle kiln. We make sure that the High Alumina Bricks offered by us have gone through all the quality control parameters for maintaining their high quality standard. Their durability and strength adds life to the structure and they possess the capacity of bearing high temperature.

Technical Data of High Alumina Brick UAL55 | ||

Physical Properties: |

|

|

Refractoriness | ℃ | 1770 |

Permanent Linear Change(1450℃×2h)% | % | 0.1~﹣0.4 |

Apparent Porosity, % | % | ≤22 |

Cold Crushing Strength | Mpa | ≥44 |

Refractoriness Under Load (T0.6) | ℃ | ≥1470 |

Thermal Expansion, % | % | ≤±0.5 |

Density | g/cm3 | - |

Chemical Analysis: |

|

|

Al2O3 | % | ≥55 |

Fe2O3 | % | - |

Note: | ||

Feature of High Alumina Brick UAL55

Good thermal shock resistance

Low porosity

Good erosion resistance

High compressive strength

Excellent high temperature mechanics

Application of High Alumina Brick UAL55

High Alumina Bricks UAL55 are mainly used:

1). As lining components for the high temperature industries furnace (such as refractory, electronics, ceramics industries).

2). As Thermal insulation components for the high temperature heating equipments, such as gas making furnace, gasification furnace of petrochemical industry, reacting furnace of non-ferrous industry, electric induction furnace of metallurgical industry.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- The difference between the two kinds of high alumina bricks is great. I perennial in Zhengzhou was responsible for the production and sale of colt refractories

- Q: Introduction of high alumina brick

- Three alumina silicate refractory product with a content of two Al2O3 (48%).

- Q: What is the density of a super high alumina brick and what is the price?

- Of course, the transaction price, please choose refractory brick manufacturer is better.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: How much is one ton / ton of high alumina refractory brick?

- The price of high alumina refractory bricks is not equal, according to the quality index of GB2988-2012

- Q: What are the high temperature refractory mortars made of?

- Products used in metallurgy, building materials, machinery, chemical, power industry, industrial thermal furnace, for masonryBuilding clay brick, high alumina brick and corundum brick have the characteristics of full grey seam, good airtightness, high bonding strength, high temperature performance and suitable construction time

- Q: What is spalling resistant high alumina brick?

- Using bauxite as main raw materials, the introduction of a small amount of ZrO2 (ZrO2 is due to phase transition, between monoclinic and tetragonal type can improve the thermal stability of the products), adding a certain amount of binder and additives, the particle size distribution control mud, forming and sintering of refractory products produced, called anti stripping high alumina brick.

- Q: What's the weight of the refractory bricks?

- According to shape and size can be divided into standard brick, ordinary brick, special brick, etc.. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: Is glass wool inorganic thermal insulation material?

- The use of glass wool, glass wool is usually used as raw materials of various types of insulation materials, such as glass wool board, glass wool, glass wool, glass wool pipe, can be used in the following areas:1) roof insulation, cold protection, sound-absorbing materials; 2) building exterior wall insulation and cold protection; 3) entertainment places, theaters, television stations, radio stations, laboratories, sound absorption treatment.

- Q: What are the categories of bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

Send your message to us

High Alumina Brick UAL55 - High Alumina Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords