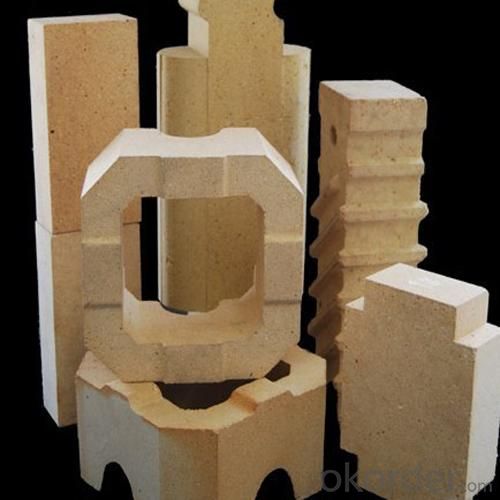

High Alumina Anchor Brick UAL60

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Anchor Brick UAL60

Our corporation’s refractory bricks include many kinds of anchor bricks, like UAL85, UAL75 and so on.

Our refractory bricks are in good quality and we can offer you the best price. Featuring huge volume density, high compressive strength, good thermal stability and strong impact resistance, all of our high-aluminum anchorage bricks, mullite anchorage bricks and burner bricks can be made into any specification defined by users to fit for different demands.

Technical Data of Anchor Brick UAL60 | ||

Physical Properties: |

|

|

Refractoriness | ℃ | 1790 |

Permanent Linear Change(1500℃×2h)% | % | 0.1~﹣0.4 |

Apparent Porosity, % | % | ≤20 |

Cold Crushing Strength | Mpa | ≥55 |

Refractoriness Under Load (T0.6) | ℃ | ≥1450 |

Thermal Expansion, % | % | - |

Density | g/cm3 | 2.35 |

Chemical Analysis: |

|

|

Al2O3 | % | ≥60 |

Fe2O3 | % | 1.5 |

Note: | ||

Features of Anchor Brick UAL60

Low thermal conductivity

Excellent acid and base slag resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Applications of Anchor Brick UAL60

Our Anchor Brick UAL60 are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc. Our refractory brick have the capacity of maintaining excellent mechanical behavior under high temperature,

CNBM has success in its refractory bricks due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in refractory brick application and would like to assist you in product selection, system design, and installation techniques. We are looking forward for your inquiry.

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: What are the requirements for refractory materials in heat treatment furnace?

- Refractoriness is the property of a refractory against high temperature, which means the temperature at which a refractory is softened to some extent after heating, but not its melting point. According to the degree of refractory, refractory materials can be divided into: General refractories, refractory degree is 1580 to 1770 DEG C; advanced refractories, refractory degree is 1770 to 2000 DEG C; special refractory material, refractory degree is greater than 2000 DEG C.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: What kind of material is the general metal case?

- Ordinary computer chassis and the material itself does not produce high-energy radiation, only in the space environment of the computer is the external defense requirements, and in the space structure, the use of lead as protective materials, unbearable weight.

- Q: What causes breakage of refractory bricks?

- There are many factors that lead to the damage of refractory brick, can be divided into: the chemical loss (e.g. salt penetration, redox phenomenon), heat loss (burning, thermal shock), mechanical loss (kiln deformation, thrust, brick masonry quality etc.).

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The current configuration of domestic calcining active lime rotary kiln refractories are as follows: the discharge end of low cement high alumina castable with 3% steel fiber; the cooling zone and the firing zone: dry magnesia spinel brick with high aluminum brick with high temperature; preheating: high alumina brick; low temperature preheating zone: clay brick light clay brick; feeding end: low cement high alumina castable with 3% steel fiber; in addition, brick size also have the corresponding requirements; dimensional tolerances: dimensional tolerances used in different parts of the requirements are not the same, the general control in 2mm; corner damage: general permit edge damage 40mm and 5mm deep within angle loss in the hot and cold surface is allowed to have only one, three edges and the length of not more than 50mm; there are cracks parallel to the use of surface crack is not allowed, cracks of brick surface are allowed.

- Q: What are the categories of bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High Alumina Anchor Brick UAL60

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords