High Alumina Brick UAL48 - High Quality Refractory Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of High Alumina Brick UAL48

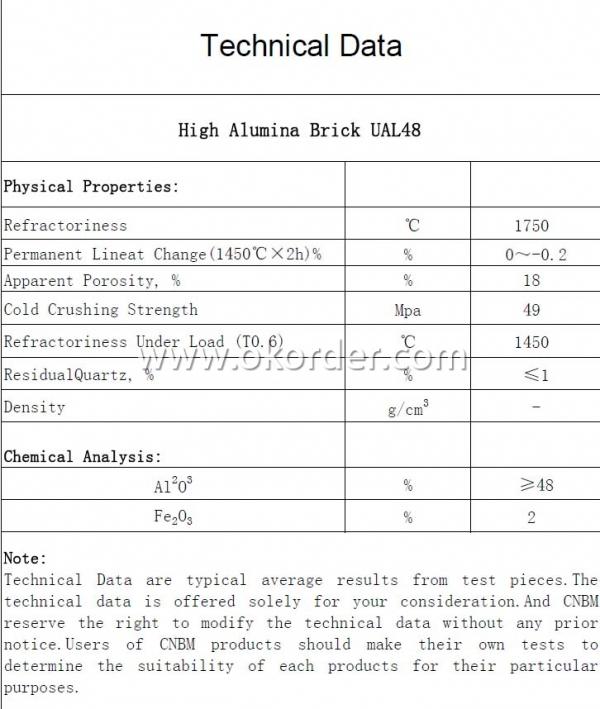

CMAX high alumina firebricks are classified According to alumina content ranging from 48% to 90%.

The high alumina brick UAL48 contains 48% alumina with low ferrous within the brick and is well made with high technology. The raw materials are purchased from the most qualified places in China.

Features of High Alumina Brick UAL48

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Application of High Alumina Brick UAL48

CMAX high alumina bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- Quality requirements for aluminium bricks of different grade. 2, high aluminum powder and high alumina aggregate and other materials of reasonable proportion, to reach the production requirements.

- Q: How many cubic bricks does a high alumina brick have?

- It is related to the content of aluminum in high alumina bricks.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- RT3 series trolley type resistance furnace is a national standard energy-saving cycle type operation furnace. It has super energy-saving structure, adopts fiber structure and saves electricity 30%. Exclusive production of composite high aluminum nails group, car anti-collision sealing brick, automatic sealing trolley and furnace door, integrated rail, without the basic installation, placed on the ground floor can be used. Mainly used for high chromium, high manganese steel castings, ductile iron, roller, steel ball, 45 steel, stainless steel quenching, annealing, aging, and various mechanical parts heat treatment. Features: 1, no noise, no environmental pollution. 2, small heat storage, less heat loss. 3, high temperature control accuracy, furnace temperature uniformity. 4, a high degree of automation, simple. 5, PID programming can be used to set, fully automatic operation. 6, good sealing, long life, safe and reliable. Widely used in chemical, petroleum, food, metallurgy, machinery, light industry, electricity, ships, paper, mining, medicine, central heating and other industrial sectors. With the development of social productive forces, its application in various industries is more and more widespread. Two, pitannealingfurnace (for example: flange heat treatment furnace) use: the furnace for metal parts, such as ring of equipment heat treatment at rated temperature: the furnace is composed of furnace body and a movable furnace cover and control system.

- Q: Density of high alumina bricks

- The density of high alumina bricks is determined according to the price. The average density is between 2.3-2.5g/cm3. The higher the density, the higher the price, the higher the aluminum bricks are in the industry. More than 2.4 are required.

- Q: What's the price of high alumina refractory bricks?

- Their refractory bricks are of good quality and low ex factory prices. Special high alumina refractory brick factory price of 1900 yuan / ton, a high alumina brick factory price of 1650 yuan / ton... This price applies to standard size, size 230*114*65mm, more products, prices go to see.

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- People with the shaft kiln cement clinker kiln, because of small size, low calcination temperature, using only Al2O3 containing a single clay brick is 30 ~ 40%, the rotary kiln was improved in the early Yuan faith this experience, use of high alumina brick and clay brick, from 60s onwards, due to large scale kiln and to strengthen the operation of the high temperature parts of kiln lining, alkaline brick masonry is widely used, the main varieties are: magnesia chrome brick, magnesia spinel brick and dolomite brick.

- Q: Can high alumina brick resist carburizing?

- The resistance to carburization is not directly related to the bulk density of bricks

- Q: Are there any differences between insulating bricks and refractory bricks?

- The insulation performance of thermal conductivity of insulating brick in general 0.2-0.4 (average temperature 350 - 25 DEG C) w/m.k, and the thermal conductivity of refractory brick in 1 (the average temperature of 350 - 25 DEG C) above w/m.k, which can obtain the insulation performance of insulating brick than refractory brick insulation performance is much better.

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: Use of high alumina refractory bricks?

- High alumina brick refractory than clay refractory bricks and brick refractory degree are higher, up to 1750~1790 DEG C, which belongs to high-grade refractory materials.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High Alumina Brick UAL48 - High Quality Refractory Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords