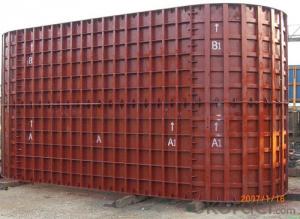

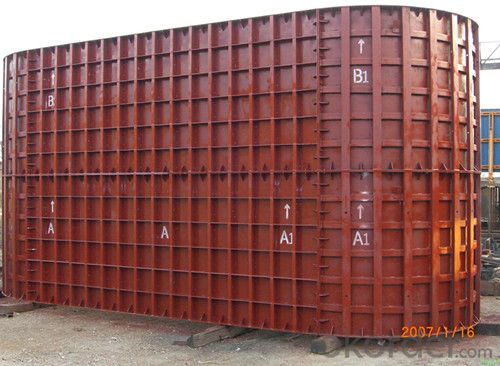

Heavy Steel Formwork for Dam Construction with Anti-Corrosion Paint

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q: Can steel formwork be easily modified or adjusted during construction?

- Yes, steel formwork can be easily modified or adjusted during construction. Steel formwork is known for its flexibility and adaptability, allowing for quick and convenient adjustments as per the project requirements. Steel formwork systems are designed to be modular, which means they can be easily assembled and disassembled, allowing for easy modification or adjustment of the formwork structure. Additionally, steel formwork can be easily cut, welded, or bolted together to create custom formwork shapes or sizes. This versatility of steel formwork makes it a preferred choice in construction projects where modifications or adjustments are frequently required.

- Q: What are the different sizes available for steel formwork panels?

- The sizes available for steel formwork panels can vary depending on the manufacturer and project requirements. However, common sizes range from 1.2 meters by 1.8 meters to 2.4 meters by 4.8 meters. These dimensions can be adjusted to accommodate different construction needs and can be found in various thicknesses and configurations.

- Q: How does steel formwork affect the overall sound insulation of the structure?

- Steel formwork does not directly affect the overall sound insulation of a structure. The purpose of steel formwork is to provide temporary support and shape to the concrete during the construction process. It is primarily used for concrete walls, slabs, columns, and beams. The sound insulation of a structure is mainly determined by the materials used for walls, floors, and ceilings, as well as the design and construction techniques employed. These factors contribute to the transmission of sound waves and the overall acoustic performance of the building. While steel formwork itself does not have inherent sound insulation properties, it can indirectly affect the sound insulation of a structure during the construction phase. If the formwork is not properly installed or secured, it may result in gaps or cracks in the concrete, which can compromise the sound insulation performance of the finished structure. However, it is important to note that any potential impact on the sound insulation of the structure due to steel formwork is temporary and can be rectified during the subsequent stages of construction, such as by using suitable acoustic insulation materials or soundproofing techniques. In summary, steel formwork does not directly affect the overall sound insulation of a structure. The sound insulation of a building is primarily determined by the materials and construction techniques used for walls, floors, and ceilings. Proper installation and subsequent measures can address any temporary impact on sound insulation caused by steel formwork during the construction process.

- Q: What are the safety considerations when using steel formwork?

- When using steel formwork, there are several important safety considerations to keep in mind. Firstly, it is crucial to ensure that the steel formwork is properly installed and secured. This means that it should be firmly supported and braced to prevent any movement or collapse during the construction process. The formwork should also be checked regularly for any signs of damage or wear and tear, as this can compromise its stability. Secondly, it is important to have proper fall protection measures in place. This includes providing workers with appropriate safety harnesses and ensuring that guardrails or barriers are installed on elevated platforms or edges where there is a risk of falling. Workers should also receive proper training on how to use these safety devices and be aware of all the potential hazards associated with working at heights. Furthermore, when working with steel formwork, it is important to consider the weight and load-bearing capacities. Steel formwork can be quite heavy, so it is important to ensure that the supporting structures and equipment, such as cranes or hoists, are capable of safely lifting and moving the formwork without causing any accidents or injuries. Additionally, it is crucial to follow proper lifting and handling techniques when working with steel formwork. This includes using appropriate lifting equipment, such as slings or chains, and ensuring that the load is evenly distributed to prevent any imbalance or strain on the workers or the equipment. Lastly, it is important to have proper communication and coordination among the workers when using steel formwork. This includes providing clear instructions and guidelines to the workers, ensuring that they are aware of any potential hazards or risks, and establishing a system for reporting any safety concerns or incidents. Overall, the safety considerations when using steel formwork revolve around proper installation, fall protection, weight and load-bearing capacities, lifting and handling techniques, and effective communication and coordination. By addressing these considerations, construction workers can minimize the risks and ensure a safe working environment.

- Q: Can steel formwork be used for both horizontal and vertical concrete placement?

- Both horizontal and vertical concrete placement can utilize steel formwork. Steel formwork is a versatile and long-lasting solution for creating molds or frames that maintain wet concrete in the desired shape until it sets and hardens. This kind of formwork is frequently employed in construction projects for various purposes, including horizontal and vertical concrete placement. Steel forms possess enough strength to withstand the weight and pressure of the concrete, which renders them suitable for vertical applications like walls, columns, and beams. Moreover, steel formwork can be easily adjusted or modified to accommodate different shapes and sizes, making it perfect for horizontal placements such as slabs, floors, and pavement. In general, steel formwork offers flexibility, strength, and stability, making it suitable for a wide range of concrete placement requirements.

- Q: Can steel formwork be used for residential construction projects?

- Residential construction projects can indeed utilize steel formwork. This option, known for its versatility and durability, presents several advantages in the realm of residential construction. It furnishes a solid and steady framework for the pouring of concrete, guaranteeing accurate and uniform shapes for walls, slabs, and other structural elements. Steel formwork proves to be highly reusable, rendering it an economical selection for residential endeavors with multiple concrete pours. It endures numerous uses and can be effortlessly assembled and disassembled, thereby expediting the construction process and reducing labor costs. Furthermore, steel formwork delivers exceptional dimensional stability, ensuring the final structure possesses precise dimensions and smooth finishes. It can withstand the pressure exerted by wet concrete, enabling the construction of high-rise buildings or structures bearing heavy loads. Moreover, steel formwork permits design flexibility, granting architects and builders the ability to fashion unique and intricate shapes within residential edifices. This adaptability renders it suitable for a diverse array of architectural styles and designs. While the initial investment for steel formwork may be higher compared to other formwork materials, its prolonged lifespan and reusability make it an economically viable solution in the long term. It also demands less maintenance and repair when contrasted with traditional timber formwork. In conclusion, steel formwork represents a fitting option for residential construction projects due to its strength, durability, reusability, dimensional stability, and design flexibility. It bestows numerous benefits and aids in the successful completion of top-quality residential structures.

- Q: How does steel formwork affect the overall aesthetics of a concrete structure?

- The overall aesthetics of a concrete structure can be significantly influenced by the use of steel formwork. Utilizing steel as a material for formwork offers numerous advantages that directly contribute to enhancing the visual appeal of the final concrete product. To begin with, the concrete surface can achieve a smooth and uniform finish through the use of steel formwork. The rigid nature of steel ensures that there are no imperfections or irregularities present on the formwork, resulting in a flawless and visually pleasing concrete structure. This is particularly important for architectural elements that aim for a sleek and polished appearance. Additionally, steel formwork allows for greater flexibility in design. By utilizing steel, it becomes possible to create complex and intricate shapes, curves, and patterns that can transform a concrete structure into a piece of art. The malleability of steel enables architects and designers to push the boundaries of creativity, resulting in visually stunning concrete structures that stand out. Moreover, steel formwork offers excellent dimensional stability. It can withstand the pressure exerted by the fresh concrete, ensuring that the formwork maintains its shape and integrity throughout the pouring and curing process. This stability prevents any deformations or distortions in the concrete, resulting in a consistent and visually appealing appearance. Furthermore, steel formwork provides superior strength and durability. This allows for the construction of larger and taller concrete structures, which can be visually impressive and impactful. The robustness of steel formwork ensures that the concrete structure remains structurally sound and visually appealing for an extended period of time. In conclusion, steel formwork plays a crucial role in enhancing the aesthetics of a concrete structure. Its ability to provide a smooth finish, offer design flexibility, maintain dimensional stability, and provide strength contributes to the creation of visually pleasing and architecturally impressive buildings. Whether it is a high-rise tower, an intricate bridge, or an iconic landmark, steel formwork helps elevate the overall aesthetics and visual impact of the concrete structure.

- Q: Can steel formwork be used for museum construction projects?

- Yes, steel formwork can be used for museum construction projects. Steel formwork is a versatile and durable option for constructing various types of structures, including museums. It offers several advantages such as high strength, adjustable sizes, reusability, and easy assembly and disassembly. Steel formwork allows for precise and accurate construction, ensuring the quality and integrity of the museum's design. Additionally, steel formwork can withstand the weight of concrete and provide a smooth finish, which is essential for preserving the aesthetic appeal of the museum. Overall, steel formwork is a suitable choice for museum construction projects due to its strength, adaptability, and ability to meet the specific requirements of such projects.

- Q: How does steel formwork contribute to the overall quality of the concrete finish?

- Steel formwork contributes to the overall quality of the concrete finish by providing a sturdy and accurate mold for the concrete to be poured into. It ensures that the concrete is poured and shaped precisely, resulting in a smooth and even finish. The durability and strength of steel formwork also prevent any deformation or movement during the curing process, leading to a more durable and long-lasting concrete structure.

- Q: Can steel formwork be used for structures with high thermal insulation requirements?

- Structures that require high thermal insulation typically do not employ steel formwork. This is due to steel's high heat conductivity, which facilitates heat transfer. Consequently, using steel formwork in such structures would result in significant heat loss and reduce the building's overall energy efficiency. To achieve optimal thermal insulation, materials with excellent thermal resistance, such as insulating concrete forms (ICFs), expanded polystyrene (EPS), or other insulated formwork systems, are preferred. These materials possess low thermal conductivity and serve as barriers against heat transfer. By utilizing these materials, structures can fulfill the demanding thermal insulation requirements and enhance energy efficiency. Nevertheless, it is important to note that steel formwork can still be utilized in conjunction with insulation materials to provide structural support and shape the structure. In this scenario, additional insulation measures, such as the application of insulation layers or the utilization of insulation inserts, would be necessary to augment the thermal performance of the structure. In conclusion, while steel formwork may be suitable for various construction projects, it is not the optimal choice for structures that necessitate high thermal insulation.

Send your message to us

Heavy Steel Formwork for Dam Construction with Anti-Corrosion Paint

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords