Fireproof Type Textile Sling Webbing Sling ODM&OEM Customization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Type Textile Sling Webbing Sling ODM&OEM Customization

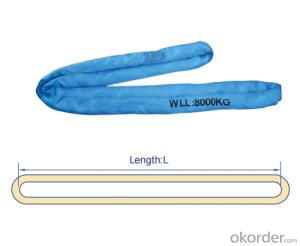

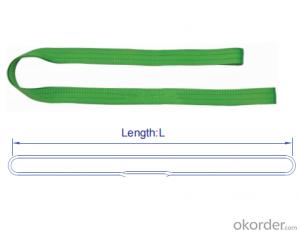

Certification: GS, CE, ISO

Customized support: OEM, ODM

Application: Lifting Goods

Safety factor: 5:1 6:1 7:1 8:1

Length: Customized Length

Width: Customized Width

Standard: CE/GS/ISO9001

Packing: Customers Requiement

MOQ: 1 Piece

Chracteristics:

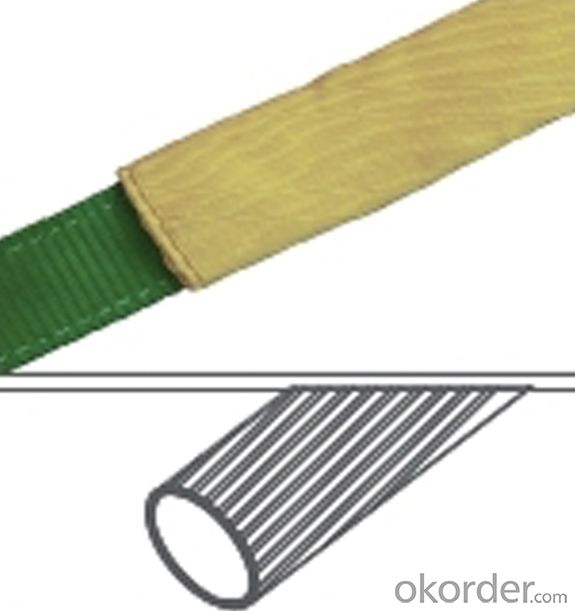

Soft, light, no harm to the cargo, safety, long life and so on.

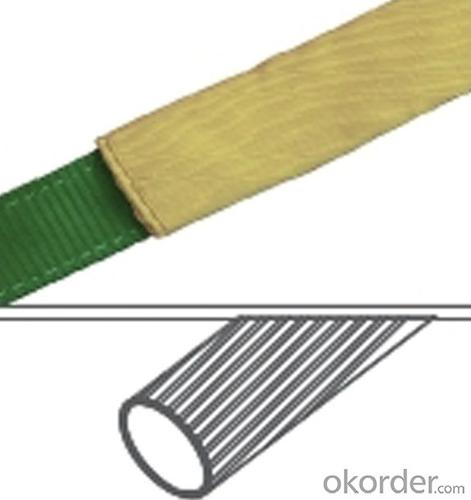

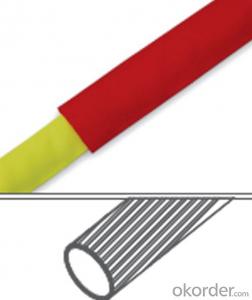

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:1.210 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

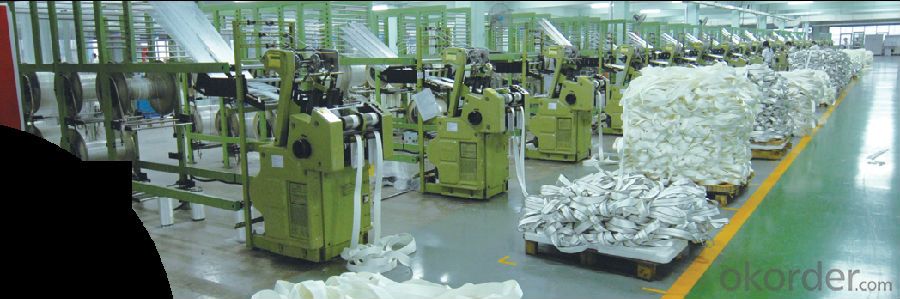

Textile sling factory is the largest base for lifting belts in the world with the production capacity "over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines "from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc. The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope "and traction rope, according to different using environments, different materials would be used, "such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene "material).

We are able to manufacture special slings such as high-strength type, flame retardant "type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant "type, fluorescent type, optical inspection type and oil and water resistant type sling. With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other "operations in machining, port handling, marine engineering, ship, electric power, transportation, "aerospace and other fields. Achievements in scientific research:In 1997, we drafted out the industrial standard for textile "slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic "progress for the Chinese textile sling industry. "In 2007, we revised JB/T8521.1-2007"Textile Sling – Safety - Part 1: Common use webbing "sling" and JB/T 8521.2-2007"Textile Sling - Safety - Part 2: Common use round sling". In 2009, we edited GB/T 23914.2-2009"Road vehicle mounted fixtures – Safety – part 2: "Synthetic ratchet strap assemblies", participated in writing TB/T 3123.11-2009"Rescue devices for "railway accidents - part 11: high-performance textile sling". In 2014, we participated in writing GB/T 30667-2014"Polyester and polyolefin dual Fiber rope "and GB/T 30668-2014"8 strands, 12 strands and multiflament braided Ultra high molecular weight "polyethylene fiber rope".

- Q: What is the line on the train for?

- The contact wire is mostly made of steel aluminum core, that is, the outside is made of steel, and the main part is the friction part of the pantograph. To ensure the conductivity and wear resistance, the aluminum core is mainly to ensure the conductivity. Copper and aluminum composite wires have also been used as contact wires.

- Q: Do cranes have the same wire ropes, slings, slings and cables?

- To be exact, different things are very relevantThe cable belongs to the sling and belongs to the spreaderA wire rope can be made into a wire rope rigging

- Q: How much is the crane arm of the tower from the residential building recently?

- (1) hook safety device: a sling that prevents the hook from slipping and is automatically slipped from the hook. A spring is arranged at the opening of the hook head to seal the opening; the spring sheet can only be pressed downwards and can not be turned upwards after being put into the sling to prevent the sling from falling off automatically.(2): reel insurance device is effective measure to prevent accidents caused by improper wire rope winding drum out outside. There are different ways to do this. The main reason is that a steel bar is welded outside the drum to restrict the wire rope to move within the reel range.(3) fixed foundation: the depth of digging pit is 600mm, the concrete is poured on the lime soil, the surface is smooth, and the waterproof and earthing protection measures are adopted.

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: What are the precautions for rigging in hoisting works?

- When lifting heavy objects, heavy is prohibited to stand.

- Q: How do you tie the wire rope?

- Manganese phosphating belongs to wear, corrosion, phosphating, automobile transmission, steel gear is through the manganese phosphating treatment, can ensure that the car gear for more than ten years without damage. Phosphating coating of steel wire rope China patent technology production, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just add the last bonderizing process, steel wire for rope wear resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope. The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of domestic smooth steel wire rope, wire rope surface is 2-3 times of imports, (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility, is currently the most advanced technology in the world of steel wire rope field. Manganese phosphating is bonderizing, can solve the problem of wire rope wear during use, smooth wire rope being eliminated, because the phosphating coating steel wire rope in short supply, the more sought after, need to ask a few companies.

- Q: The wire rope lock can hang a lot of things

- The crane used in atmospheric environment, preferably manganese phosphide coating, steel wire rope, heavy corrosive environment, preferred hot-dip galvanized double phosphating steel wire rope, priority wire rope in sea water. Please note that at the time of purchase, in the purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope or 316 stainless steel wire rope, to protect their legitimate rights and interests, in addition, patent products are generally in the rope on the outer packing of a patent spraying label, warranty should be the main technical indicators, such as the type of phosphating film and film, for reference

- Q: What are the selection principles for lifting cranes?

- To avoid the use of large lifting capacity of the crane lifting capacity of small parts, small crane overload lifting component, or choose not modified after the actual loading test of crane hoisting, shift or use the high cost of equipment.

- Q: Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q: Notice of tower crane?

- The metal structure of the tower crane, the track and the metal shell of all the electrical equipment shall have reliable earthing devices, and the grounding resistance shall not be greater than 4 ohms, and lightning protection devices shall be set up.Fourth. Pole arrangement, each attachment device attached to the wall and spaced distance should be in accordance with the provisions of the original factory, homemade bar design calculations should be.

Send your message to us

Fireproof Type Textile Sling Webbing Sling ODM&OEM Customization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches