Aluminum Foil Facing Heat Shield Insulation Bubble Foil Shielding Copper Polyester Foil for Coaxial Cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

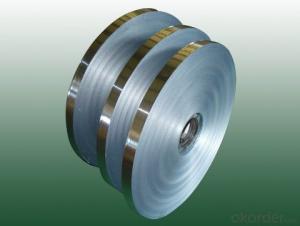

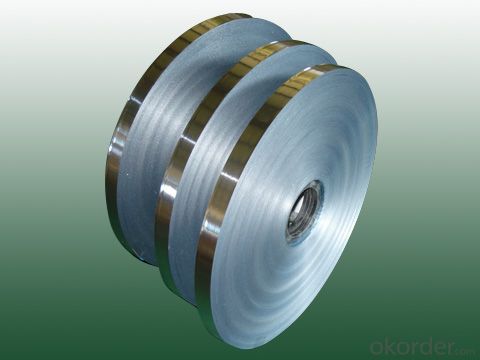

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

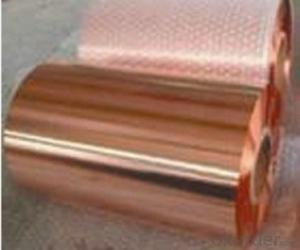

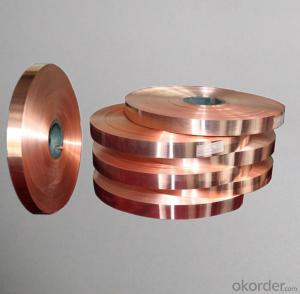

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: The user is asking if they can reuse their old aluminum foil facing to create new ones once it becomes worn out.

- <p>No, you cannot create new aluminum foil facings from old, worn-out ones. Aluminum foil facings are typically made from a specific type of aluminum that is bonded to a substrate. Once it wears out, the aluminum layer is compromised and cannot be reused to make new facings. Recycling old aluminum foil is the best option to reduce waste and conserve resources. You can recycle aluminum foil, which will then be processed and turned into new aluminum products.</p>

- Q: Is it possible to use aluminum foil facing to cook a fried egg?

- <p>Yes, you can use aluminum foil facing to make a fried egg. Place a piece of aluminum foil on a flat surface and lightly grease it. Crack the egg into the center of the foil, season as desired, and fold the foil over the egg to create a sealed pouch. Heat a non-stick pan over medium heat and place the foil pouch inside. Cook for about 3-4 minutes on each side or until the egg is cooked to your liking. Be cautious when opening the foil as steam will escape. This method is a creative alternative for cooking eggs without using a traditional pan.</p>

- Q: Is it safe and practical to use aluminum foil facing as a protective layer for a cutting board?

- <p>Yes, you can use aluminum foil facing as a temporary cover for a cutting board. It provides a smooth surface that can protect the cutting board from scratches and stains. However, it's not recommended for long-term use or heavy-duty cutting as it may tear or dent easily. For regular use, a proper cutting board cover or a plastic cutting mat is more durable and safer.</p>

- Q: This question asks for signs or methods to identify if the aluminum foil facing of a product, such as insulation or a jacket, is damaged or defective.

- <p>To determine if your aluminum foil facing is damaged or defective, look for visible signs such as tears, punctures, or holes. Check for any discoloration or rust, which could indicate corrosion. The foil should be smooth and uniform; any irregularities or bubbling might suggest a defect. Additionally, test the integrity by gently pulling or pressing the foil鈥攊f it easily tears or crumples, it may be compromised. For insulation, a damaged foil facing can lead to reduced effectiveness in heat or cold retention, so also consider the performance of the item.</p>

- Q: This question asks for a method to clean aluminum foil after cooking to get rid of excess oil.

- <p>To remove excess oil from aluminum foil after cooking, first let the foil cool down to avoid burns. Then, you can use a paper towel or a clean cloth to gently wipe away the oil. For stubborn oil, you can wash the foil with warm soapy water. If you're reusing the foil, make sure it's thoroughly dried before storing to prevent any potential for bacterial growth. Always remember to handle aluminum foil with care as it can be sharp and may tear easily.</p>

- Q: What are the methods to stop the aluminum foil from curling at the edges while cooking?

- <p>To prevent the edges of aluminum foil from curling up during cooking, you can dampen the edges with a little water or cooking oil. This helps to weigh down the foil and keep it flat. Additionally, you can fold the edges inward to create a small rim, which can help contain the food and prevent the foil from lifting. Another method is to use a heavier object, such as a ceramic dish or a small pan, to press down on the foil, keeping it in place. Ensure that the object is heat-resistant and won't react with the foil. These techniques can help maintain the integrity of your foil and keep it from curling up during the cooking process.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foil facing, focusing on their differences.

- <p>Aluminum foil facing is distinct from other metal foil facings due to its unique properties. It is lightweight, highly reflective, and offers excellent heat resistance. It's also non-toxic and has good barrier properties against oxygen and moisture, making it ideal for food packaging and insulation. Other metal foils, such as copper or stainless steel, may have different thermal or electrical conductivity properties, and are often heavier and less flexible. Copper, for instance, has higher electrical conductivity but is less common in foil applications due to cost and weight. Stainless steel foils are more durable and corrosion-resistant but are not as reflective or lightweight as aluminum. Each type of metal foil has specific applications based on its unique characteristics.</p>

- Q: The user is asking if it's possible to use aluminum foil with a shiny side facing outward to create a sandwich roll.

- <p>Yes, you can use aluminum foil to make a sandwich roll, but it's not recommended to use the shiny side facing outward. The dull side of the foil is typically used for food contact because it's less likely to transfer any potential residues or chemicals to the food. The shiny side may have a coating that isn't safe for direct food contact. Always ensure that the foil is food-safe and use it according to the manufacturer's instructions.</p>

- Q: Is it safe to use aluminum foil facing inside a pressure cooker and does it pose any risks?

- <p>Using aluminum foil facing in a pressure cooker is generally safe and is commonly used to prevent food from sticking to the pot. However, it's important to ensure that the foil does not block the pressure release valve or the vent, as this could lead to a buildup of pressure and potentially cause the cooker to malfunction. Always follow the manufacturer's guidelines for your specific pressure cooker model to avoid any safety issues.</p>

- Q: Is it safe to use aluminum foil facing to wrap hot food?

- <p>Yes, you can use aluminum foil facing to wrap hot food. Aluminum foil is a safe and common material for food packaging, especially for wrapping and cooking food in the oven. It's important to ensure that the foil is food-grade and not damaged or punctured, as this could lead to contamination. Additionally, avoid wrapping acidic foods at high temperatures as this can cause the foil to react and potentially release aluminum into the food. When in doubt, check the manufacturer's guidelines for safe use with hot foods.</p>

Send your message to us

Aluminum Foil Facing Heat Shield Insulation Bubble Foil Shielding Copper Polyester Foil for Coaxial Cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords