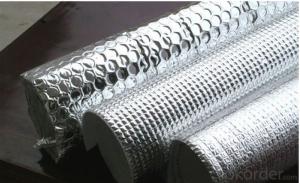

Aluminum Foil Facing Heat Shield Insulation Bubble Foil with Aluminium Cable Shield Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

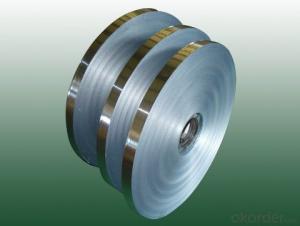

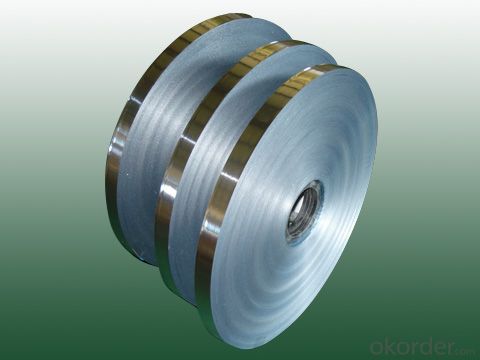

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What distinguishes various grades of aluminum foil sheets from one another?

- <p>Different grades of aluminum foil sheets are distinguished by their thickness, strength, and purity. Grade 1 is the purest and softest, used for food wrapping and baking. Grade 2 is harder and more tear-resistant, suitable for heavy-duty use like grilling. Grade 3 is an alloy and offers high strength and durability, often used in industrial applications. Grade 4 is a heat-treatable alloy, providing high strength and used in aerospace and automotive industries. Each grade has specific applications based on its unique properties.</p>

- Q: This question asks about the proper way to store aluminum foil to keep it facing the right way for easy use.

- <p>To store aluminum foil facing the right way, first use up one side completely. Then, fold the remaining foil in half with the shiny side facing out. Place the folded foil back into the box or container, shiny side up. When you need to use it next, the shiny side will be facing you, making it easy to tear off. To keep it flat and wrinkle-free, you can place a piece of cardboard inside the box, or roll it around a clean, empty paper towel tube.</p>

- Q: What are some suggestions to ensure plastic containers are used in a more hygienic and long-lasting manner?

- <p>To use plastic containers more hygienically and durably, follow these tips: 1) Always wash containers with warm soapy water and rinse thoroughly before and after each use. 2) Avoid putting hot foods or liquids directly into plastic containers to prevent warping and potential chemical leaching. 3) Do not use scratched or damaged containers as they can harbor bacteria and are more likely to break. 4) Store containers in a dry, cool place away from direct sunlight to prevent degradation. 5) Regularly inspect containers for signs of wear and replace them when necessary. 6) Use containers within their recommended temperature range to maintain their integrity and safety.</p>

- Q: Is it appropriate to store medications using aluminum foil facing?

- <p>Aluminum foil facing is not recommended for storing medicines. While it can provide a barrier against light and air, it is not an ideal storage medium due to potential chemical reactions between the aluminum and certain medications. Medicines should be stored in their original containers with proper labels, away from light and heat, and as directed by the manufacturer or pharmacist. Using aluminum foil can lead to degradation of鑽晥 and potential contamination.</p>

- Q: Is it safe to reuse aluminum foil for food packaging purposes?

- <p>While it may be tempting to reuse aluminum foil for food packaging, it is generally not recommended due to hygiene and safety concerns. Recycled aluminum foil can harbor bacteria and other contaminants, which can be transferred to the food. Additionally, the foil can tear easily when reused, leading to potential food waste. It's best to use fresh aluminum foil each time to ensure food safety and maintain the integrity of your packaging.</p>

- Q: What are the various materials used as facings for aluminum foil, and how do they differ from one another?

- <p>Aluminum foil facing materials are used in construction and insulation to provide a barrier against air and moisture. The different types include: 1) Kraft paper facing, which is a strong, absorbent paper used for general purposes; 2) Glassine facing, a thin, glossy paper with good water resistance; 3) PE-coated facing, where a layer of polyethylene is applied for enhanced water resistance; 4) Aluminum foil facing, which is a thin layer of aluminum for superior barrier properties; 5) Silicone-treated glass fabric, offering high-temperature resistance and used in high-performance applications. Each type has unique properties affecting their use in various applications.</p>

- Q: Is it possible to recycle aluminum foil facing multiple times? If yes, what is the process involved?

- <p>Yes, aluminum foil facing can be recycled multiple times. The recycling process involves collecting and sorting aluminum waste, which is then shredded or crushed. The material is melted in a furnace at high temperatures, and the molten aluminum is poured into molds to form new products. This process can be repeated indefinitely without losing the quality of the aluminum, making it one of the most recycled materials globally. The recycling of aluminum saves energy and reduces the environmental impact compared to producing aluminum from raw materials.</p>

- Q: This question asks for the method to wrap a hot pan using aluminum foil, with specific instructions on how the foil should face.

- <p>To wrap a hot pan with aluminum foil, first ensure the pan is stable and on a heat-resistant surface. Take a large piece of aluminum foil, about twice the size of the pan. Hold one corner of the foil and drape it over the pan, allowing the shiny side to face the pan. Gently press the foil against the pan, working your way around the edges to cover the entire surface. Ensure the foil is snug but not too tight to avoid tearing. The shiny side facing the pan will help reflect heat and protect the pan's surface. Be cautious while handling the hot pan and aluminum foil to avoid burns.</p>

- Q: This question asks for methods to prevent food from sticking to the aluminum foil surface during cooking.

- <p>To prevent food from sticking to the surface of aluminum foil when cooking, you can lightly coat the foil with a thin layer of cooking oil or non-stick spray before placing the food on it. This creates a barrier between the food and the foil. Additionally, ensure the foil is not torn or damaged, as this can cause food to stick. Using a heavier gauge foil can also help reduce sticking. Finally, avoid overcrowding the food on the foil, as this can cause it to stick due to uneven cooking and steam build-up.</p>

- Q: This question asks for the optimal methods of storing food in containers not made of traditional food-safe materials.

- <p>The best ways to store food in containers made from alternative materials involve ensuring the containers are food-safe and do not impart any harmful substances to the food. For glass containers, ensure they are free of lead and are properly sealed to maintain freshness. For stainless steel containers, avoid those with non-food-grade coatings and ensure they are well-sealed to prevent spoilage. For silicone or plastic containers, look for BPA-free options and avoid high temperatures that could cause the material to leach chemicals. Always check for any odors or tastes that the container might impart to the food, and never store acidic foods in non-acid-resistant containers as this can lead to chemical reactions and contamination.</p>

Send your message to us

Aluminum Foil Facing Heat Shield Insulation Bubble Foil with Aluminium Cable Shield Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords