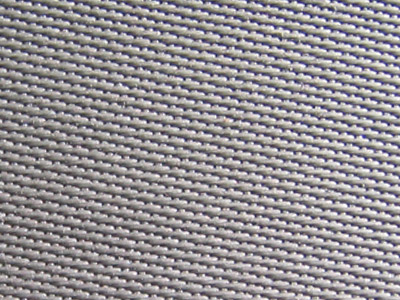

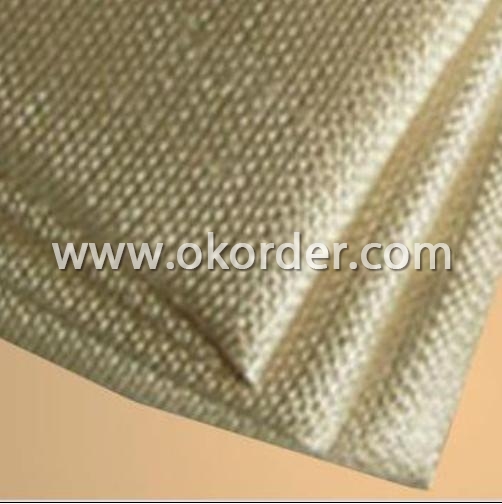

Heat Treated E- Glass Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General infor of Heat Treated E- Glass Fiber Fabric

It is fiberglass cloth impregnated our special formulated Hi-temp. resistance solutions which provides short temperature resistance of 1000C degree and increased continuous temperature resistance temperature up to 750C degree.

This impregnation also increases the products’ abrasion resistance and adds to its ability to withstand direct flame.

Product Feature of Heat Treated E- Glass Fiber Fabric

Mat width ranges from 50mm-3120mm Uniform density ensures consistent fiberglass content and mechanical properties of the final products the mats feayure good mat integrity ,low fuzz,less material waste and small roll dia meter. Excellent flexibility ensures good moldability with no springback at sharp angles, fast and consistent wet-out speed in high dry and wet tensile strength and good transparency.

Product Application of Heat Treated E- Glass Fiber Fabric

Emulsion Chopped Strand Mat is mainly applied to unsaturated polyester ,viny ester and epoxyresins. The product is most widely used in hand lay-up process and also can be used in filament winding. compression molding and continuous laminating processes. The typical end products including various panels, boats,ba

- Q: How are glass fiber textiles used in the electronics industry?

- Glass fiber textiles are used in the electronics industry for various applications, primarily for thermal management and insulation purposes. They are commonly used as reinforcements in printed circuit boards (PCBs) and as insulating materials in electrical cables and wires. Glass fiber textiles help in improving the mechanical strength and durability of electronic components, while also providing electrical insulation and heat resistance, making them essential for the efficient functioning and longevity of electronic devices.

- Q: What is the cost of glass fiber textiles?

- The cost of glass fiber textiles can vary depending on various factors such as the type and quality of the textile, the quantity being purchased, and the supplier. On average, glass fiber textiles can range in price from $2 to $10 per square yard. However, it is important to note that these prices are approximate and can vary significantly. Additionally, specialized or custom-made glass fiber textiles may be priced higher. It is recommended to contact suppliers and request quotes to get accurate and up-to-date pricing information for specific glass fiber textiles.

- Q: Can glass fiber textile be used in antennas?

- Yes, glass fiber textile can be used in antennas. It is a common material choice for antenna construction due to its low signal loss, high durability, and resistance to environmental factors such as moisture and UV radiation. Glass fiber textile also provides excellent mechanical strength and flexibility, making it suitable for various antenna designs and applications.

- Q: How do glass fiber textiles resist fading?

- Glass fiber textiles resist fading because they are made from inorganic materials that are inherently resistant to UV radiation and do not absorb or react with sunlight.

- Q: Can glass fiber textiles be used in marine applications?

- Yes, glass fiber textiles can be used in marine applications. Glass fiber textiles are known for their excellent strength, durability, and resistance to corrosion, making them a suitable material for various marine applications. They are commonly used in the construction of boats, yachts, and other marine vessels where their high tensile strength and lightweight properties are highly valued. Glass fiber textiles are also used in the manufacturing of marine equipment such as hulls, decks, and components that require high strength-to-weight ratios. Additionally, glass fiber textiles are resistant to water and chemicals, making them an ideal choice for marine applications where exposure to these elements is common.

- Q: Are glass fiber textiles resistant to heat or flame?

- Glass fiber textiles exhibit remarkable heat and flame resistance. Fiberglass, or glass fiber, is produced by weaving incredibly thin glass strands into fabric. With an exceedingly high melting point, typically reaching 700°C (1292°F), glass fiber serves as an outstanding material for situations necessitating heat resistance. It possesses a non-flammable quality, making it difficult to ignite and incapable of propagating flames. Moreover, glass fiber textiles offer effective heat insulation, rendering them a popular choice for thermal insulation materials. All in all, glass fiber textiles are renowned for their exceptional ability to withstand heat and flames.

- Q: Can glass fiber textiles be glued?

- Yes, glass fiber textiles can be glued using specialized adhesives designed for bonding glass and other materials.

- Q: How does glass fiber textile perform under mechanical stress?

- Glass fiber textile is known for its excellent performance under mechanical stress. Due to its unique structure and composition, it exhibits high strength and durability, making it resistant to various types of mechanical stress. When subjected to tensile stress, glass fiber textile can withstand significant pulling forces without breaking. Its high tensile strength allows it to distribute the applied load evenly across its structure, preventing localized stress concentrations that could lead to failure. This property makes glass fiber textile suitable for applications that require high strength, such as in the construction industry for reinforcing concrete and composites. Glass fiber textile also performs well under compressive stress. It can bear heavy loads without experiencing significant deformation or compression failure. This property is advantageous in applications where materials need to bear compressive forces, such as in infrastructure projects like bridges and columns. Moreover, glass fiber textile has good resistance to bending and flexing stress. It can withstand repeated bending without losing its structural integrity or suffering from fatigue failure. This makes it suitable for applications where flexibility and resilience are required, such as in the manufacturing of sporting goods and aerospace components. In addition to its mechanical strength, glass fiber textile also possesses excellent resistance to impact stress. It can absorb and dissipate the energy generated by impacts, minimizing the risk of damage or fracture. This property makes glass fiber textile ideal for applications that require impact resistance, such as in the automotive industry for manufacturing body panels and crash structures. Overall, glass fiber textile performs exceptionally well under mechanical stress. Its high tensile strength, compressive strength, resistance to bending and flexing, and impact resistance make it a reliable and versatile material for various demanding applications.

- Q: What are the advantages of using glass fiber textiles in construction?

- There are several advantages of using glass fiber textiles in construction. Firstly, glass fiber textiles are incredibly strong and durable. They have a high tensile strength, meaning they can withstand heavy loads and resist deformation. This makes them particularly suitable for applications that require structural reinforcement, such as reinforcing concrete or providing support in areas prone to earthquakes or other natural disasters. Secondly, glass fiber textiles are lightweight. Compared to traditional construction materials like steel or concrete, glass fiber textiles are much lighter, making them easier to handle and transport. This not only reduces the overall weight of the structure but also facilitates faster construction and installation. Thirdly, glass fiber textiles are highly resistant to corrosion and moisture. Unlike metals that can rust or deteriorate over time, glass fiber textiles do not rot, corrode, or degrade when exposed to moisture or harsh environmental conditions. This makes them ideal for applications in humid or wet environments, such as swimming pools, bathrooms, or coastal areas. Additionally, glass fiber textiles have excellent thermal and acoustic insulation properties. They can effectively trap and retain heat, reducing energy consumption and improving the energy efficiency of buildings. Moreover, they can absorb and dampen sound, improving acoustics and reducing noise pollution within the structure. Furthermore, glass fiber textiles are fire-resistant. They do not burn, emit toxic fumes, or contribute to the spread of flames, making them a safe choice for construction. This fire resistance can help prevent the rapid spread of fires and potentially save lives. Lastly, glass fiber textiles offer design flexibility. They can be easily molded, shaped, or woven into various forms, allowing architects and designers to create aesthetically pleasing structures. Additionally, they can be colored, painted, or coated to match any desired finish or appearance. In conclusion, the advantages of using glass fiber textiles in construction include their strength, lightweight nature, resistance to corrosion and moisture, thermal and acoustic insulation properties, fire resistance, and design flexibility. These characteristics make them a valuable material choice for a wide range of construction applications.

- Q: Are glass fiber textiles resistant to creasing?

- Yes, glass fiber textiles are resistant to creasing.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Heat Treated E- Glass Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords