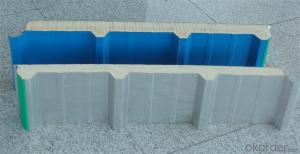

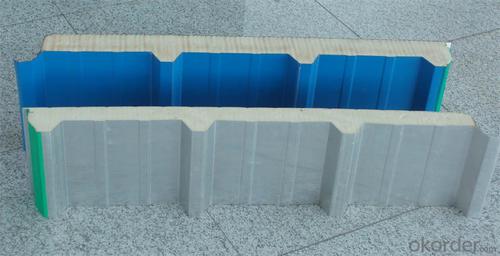

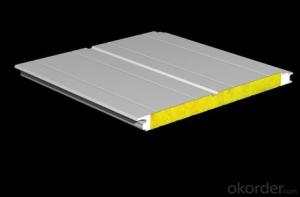

Heat and Sound Insulation Color Steel PU SandWich Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Sandwich panels are used in those applications where high structural rigidity and low weight is required. An evident example of use of sandwich panels is aircraft where mechanical performance and weight saving is essential. Other applications include packaging (e.g. fluted polypropylene boards of polypropylene honeycomb boards), transportation and automotive as well as building & construction.

Specifications

PU Color Steel SandWich Panel

1.Fireproof

2.Heat Insulating

3.Density:40kg/cbm

Product Description

1. Heat and sound insulation. Temperature suitable for PU ranges from -200 centigrade to 150 centigrade.

2. Good chemical resistance, waterproof, anti-corrosion, insect-free etc.

3. Advanced Tech: Automatic rolling machines make the whole process of manufacture effective.

4. Energy conservation, environmental protection, economical, heat insulting, good structure, easy-doing construction

5. Light weight enough to reduce building expense.

6. Time can be saved on a building project due to the simple installation

Size

Item Data

Effective Width: 1150MM/960MM/950MM

Length: Can be customized

Materials: foam board(EPS), Color steel sheet

Structure: Upper and lower layer: Color steel sheet

Middle: EPS foam board

Density of Core Material: 36-45KG/m3

Thickness of color steel sheet: 0.3-0.8MM

Colors: Blue, white or according to your requirements

- Q: What are the safety precautions when handling steel sheets?

- To ensure the well-being of individuals and prevent accidents while handling steel sheets, it is crucial to adhere to several safety precautions. These precautions encompass: 1. Personal Protective Equipment (PPE): Wearing appropriate PPE is crucial. This typically includes safety goggles or glasses, gloves, and steel-toed boots. PPE safeguards against potential injuries like cuts, burns, and eye damage. 2. Correct Lifting Techniques: Given their weight and awkwardness, utilizing proper lifting techniques is vital to avoid strain or injury. Lift with your legs, not your back, and employ team lifting when necessary. Refrain from abrupt or jerky movements while handling the sheets. 3. Secure Storage and Transport: To prevent shifting or falling, ensure proper securing when storing or transporting steel sheets. Employ suitable equipment like straps or chains to secure the sheets, distributing them evenly for balance. 4. Clear Work Area: Prior to handling steel sheets, clear the work area of obstacles or debris. This minimizes tripping or slipping hazards and enables a smooth path for moving the sheets. 5. Adequate Lighting: Good visibility is essential during steel sheet handling. Insufficient lighting heightens the risk of accidents and injuries, so ensure the work area is well-lit to avert any potential mishaps. 6. Training and Education: Individuals handling steel sheets must receive adequate training and education on safe handling procedures. This entails understanding the weight and dimensions of the sheets, as well as employing correct lifting and moving techniques. 7. Awareness of Sharp Edges: Steel sheets often possess sharp edges that can cause cuts or lacerations. Always handle the sheets cautiously and be mindful of any sharp edges. If necessary, utilize protective guards or edge protectors to minimize the risk of injury. 8. Regular Maintenance and Inspection: Regularly inspect the steel sheets for signs of damage, like sharp edges, rust, or structural weaknesses. Replace or repair any damaged sheets to ensure safe handling. By adhering to these safety precautions, individuals can minimize the likelihood of accidents and injuries while handling steel sheets. Prioritizing safety and taking necessary steps to protect oneself and others in the work environment is of utmost importance.

- Q: What are the common uses for steel sheets?

- Steel sheets have a wide range of common uses, including construction, automotive manufacturing, shipbuilding, appliance production, and fabrication of various industrial equipment.

- Q: What is the typical hardness range for steel sheets?

- The typical hardness range for steel sheets can vary depending on the specific type of steel and its intended application. However, a common hardness range for steel sheets is between 20 and 60 on the Rockwell C scale.

- Q: What are the standard dimensions for steel sheets?

- The standard dimensions for steel sheets vary depending on the specific type and grade of steel, but commonly used dimensions include 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet.

- Q: How do steel sheets perform in corrosive environments like saltwater?

- Steel sheets can be prone to corrosion in saltwater environments due to the presence of chloride ions. However, their performance can vary depending on the type of steel and the protective measures taken. Stainless steel sheets, for example, contain chromium which forms a passive layer that prevents corrosion. Additionally, surface treatments such as galvanization or applying protective coatings can further enhance their resistance to corrosion in saltwater.

- Q: What are the common tolerances for steel sheets?

- The common tolerances for steel sheets typically vary depending on the specific application and industry standards. However, some common tolerances for steel sheets include thickness variations, flatness, and width and length dimensions. These tolerances are often specified in accordance with recognized industry standards such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization).

- Q: What are the different surface finishes for stainless steel sheets?

- Some of the different surface finishes for stainless steel sheets include brushed, mirror, satin, and bead blasted finishes.

- Q: How can steel sheets be protected from rusting?

- Steel sheets can be protected from rusting through various methods. One common way is to apply a protective coating on the surface of the steel. This can be done by painting the steel sheets with a corrosion-resistant paint or by using a galvanizing process. Galvanizing involves coating the steel sheets with a layer of zinc, which acts as a barrier against moisture and prevents the steel from coming into direct contact with oxygen and water, thus reducing the risk of rust formation. Another method to protect steel sheets from rusting is through the use of corrosion inhibitors. These inhibitors can be added to the water or oil used to cool or lubricate the steel sheets, forming a protective film on the surface. This film acts as a barrier, preventing the steel from corroding. Regular maintenance and proper storage of steel sheets is also crucial in preventing rust formation. Keeping the steel sheets in a dry environment and avoiding exposure to moisture and harsh chemicals can help prolong their lifespan and prevent rusting. Additionally, using stainless steel sheets is another effective way to avoid rusting. Stainless steel contains a high amount of chromium, which forms a passive protective layer on the surface. This layer acts as a shield against corrosion and prevents rust formation. Overall, protecting steel sheets from rusting requires a combination of protective coatings, corrosion inhibitors, proper storage, and maintenance. By implementing these measures, the lifespan of steel sheets can be significantly extended, ensuring their durability and functionality.

- Q: Are steel sheets resistant to electromagnetic interference?

- Yes, steel sheets are generally resistant to electromagnetic interference due to their high electrical conductivity and ability to block external electromagnetic fields.

- Q: What are the different edge finishes available for steel sheets?

- Some of the different edge finishes available for steel sheets include mill edge, sheared edge, slit edge, deburred edge, and rounded edge.

Send your message to us

Heat and Sound Insulation Color Steel PU SandWich Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords