Geoweb HDPE Steel Plastic Compound Complex Building Pavement Geocells

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

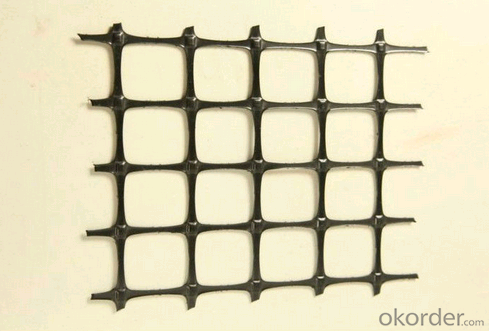

Black 100% new raw material steel plastic geogrid

suppliers from china

Description

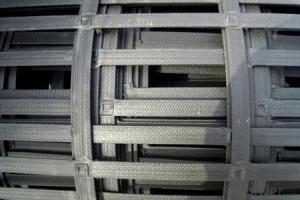

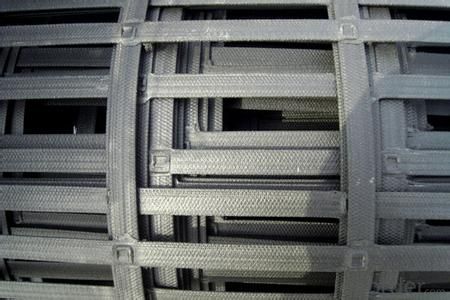

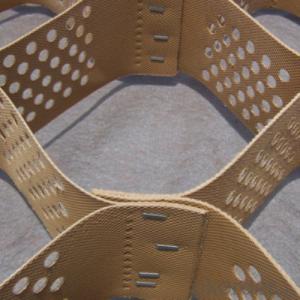

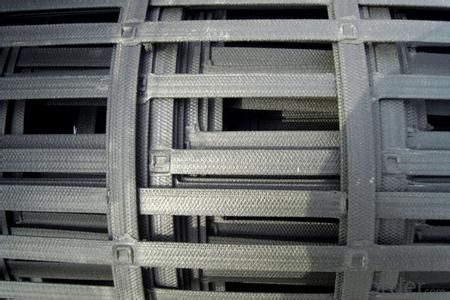

Plastic biaxial geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips. The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

Application

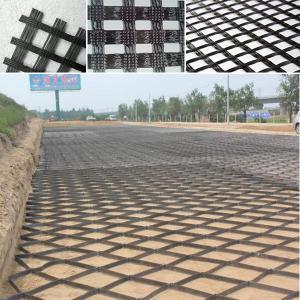

Make reinforcement treatment for varions kinds of sot soil foundation and strengthen shearing resistance of the soil body,used in reinforcement of retaining wall and widening of old road.

It is also used as protect-support net in the coal mine when layer mining of thick (coal) seam, and support of road way in the coal mine.

Specification

| Specifications | GSZ30- 30 | GSZ40-40 | GSZ50-50 | GSZ60-60 | GSZ80-80 | GSZ100- 100 | GSZ150-150 |

| Tensile Strength KN/m(LD) | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 |

| Tensile Strength KN/m(TD) | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 |

| Elongation Rate(LD TD) | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| Tensile Strength at 1% Elongation Rate(LD) | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 |

| Tensile Strength at 1% Elongation Rate(TD) | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 |

| Limit PeelForce at Welded Bonded Point N | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 |

| Products in the range of coal mine | Fire out time from outer flam | ≤3 | |||||

| Surface resistivity | <1×109< span=""> | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q: Can geogrids be used in reinforcement of bridge abutments on expansive soils?

- Yes, geogrids can be used in the reinforcement of bridge abutments on expansive soils. Geogrids are typically made from high-strength materials such as polyester or polypropylene, which provide improved tensile strength and stability to the soil. By placing geogrids in the soil around the bridge abutments, they can help distribute the load and reduce potential soil movement caused by expansive soil conditions. This reinforcement technique can effectively enhance the stability and longevity of bridge abutments on expansive soils.

- Q: Can geogrids be used in landfill capping systems?

- Yes, geogrids can be used in landfill capping systems. Geogrids are often used as reinforcement materials in landfill capping systems to enhance stability, prevent erosion, and provide long-term support for the capping layer. They are placed between layers of soil or other materials to improve the overall performance and effectiveness of the landfill capping system.

- Q: Are geogrids resistant to UV radiation?

- Yes, geogrids are generally resistant to UV radiation. They are designed to withstand prolonged exposure to sunlight without significant degradation or loss of performance.

- Q: What are the advantages of using geogrids?

- Geogrids offer several advantages in civil engineering and construction projects. Firstly, they enhance soil stability and reinforce weak soils, preventing soil erosion and improving load-bearing capacity. Secondly, geogrids can reduce construction costs by allowing for the use of locally available and lower-quality materials instead of expensive fill materials. Additionally, they provide long-term durability, resistance to chemical degradation, and high tensile strength, ensuring the longevity and structural integrity of the project. Moreover, geogrids are easy to install, lightweight, and flexible, making them convenient for various applications and reducing labor requirements. Overall, using geogrids results in improved soil performance, cost-effectiveness, and efficient construction processes.

- Q: Can geogrids be used in mining tailings management?

- Yes, geogrids can be used in mining tailings management. Geogrids are commonly used in the mining industry to reinforce soil and stabilize slopes. In the context of tailings management, geogrids can be used to improve the stability and strength of tailings dams or containment structures, preventing erosion and potential environmental hazards. Additionally, geogrids can enhance the consolidation and dewatering of tailings, facilitating their proper management and reducing the risk of environmental contamination.

- Q: Can geogrids be used in underground tunnels?

- Yes, geogrids can be used in underground tunnels. Geogrids are commonly used in tunnel construction to reinforce the surrounding soil or rock, providing additional stability and reducing the risk of ground movement. They help distribute the loads and prevent soil or rock collapse, ensuring the safety and longevity of the tunnel structure.

- Q: Is it possible to add fiberglass grille between asphalt pavement and asphalt pavement

- First look at the drawing design requirements

- Q: Can geogrids be used in erosion control on riverbanks?

- Yes, geogrids can be used in erosion control on riverbanks. Geogrids are commonly used to reinforce soil and prevent erosion by providing stability and strength to the ground. When properly installed, geogrids can effectively control erosion on riverbanks by preventing soil movement and promoting vegetation growth.

- Q: What are the factors that affect the creep behavior of geogrids?

- There are several factors that can affect the creep behavior of geogrids. These include the type and quality of the geogrid material, the load applied to the geogrid, the duration of the load, the temperature and moisture conditions, and the installation and construction methods used.

- Q: Can geogrids be used in reinforcement of rail embankments and cuttings?

- Yes, geogrids can be used in the reinforcement of rail embankments and cuttings. Geogrids provide additional strength and stability to the soil, preventing erosion and reducing the risk of slope failure. They are commonly used in railway infrastructure projects to enhance the performance and longevity of rail embankments and cuttings.

Send your message to us

Geoweb HDPE Steel Plastic Compound Complex Building Pavement Geocells

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords