Geomembrana Sodimac HDPE Geomembrane Liner for Landfill Capping

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane Introduction

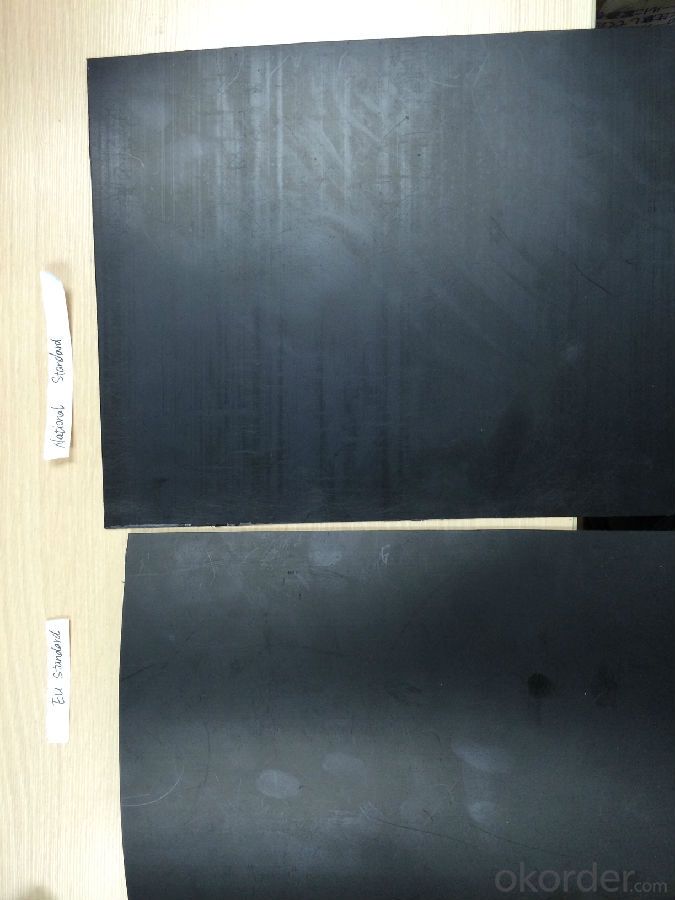

HDPE Geomembrane is a kind of waterproof material with basic raw material of high molecular polymer. Its material is HDPE.

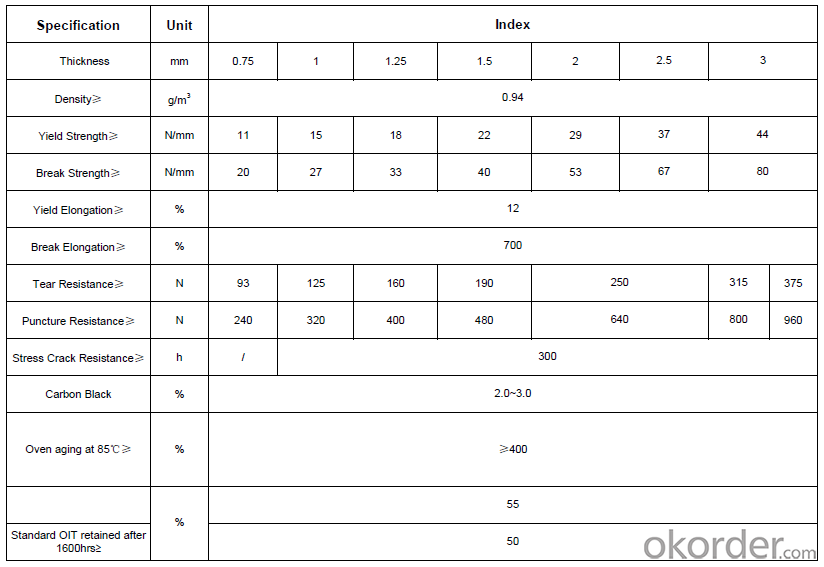

Geomembrane Specification

1)Material: LDPE

2)thickness:0.3mm~3.0mm

3)width:2m~7m

]]Product Package:

1. PE film inside, and Woven bag outside.

2. Packaged in container.

Product Application:

Product Application:

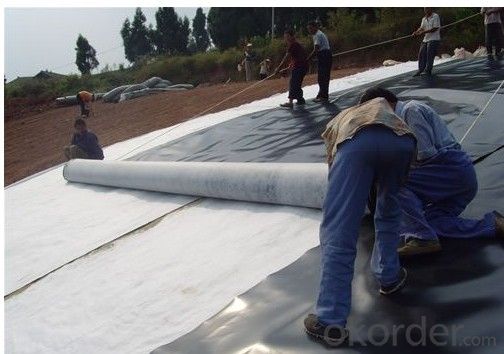

Landfill lining

Landfills capping

Water reservoirs

Pond-lining

Irrigation canals

Tunnels

Product Advantage

1.Some raw materials are produced by ourselves, or imported from overboard, so we could control the cost and quality to competitive in the market.

2. We have research team and laboratory, so we could research new products by ourselves and produce according client’s request.

3. There are more than fifty produce lines, so we could guarantee the delivery time.

4. We supply our products to many national projects in many countries, so our quality is stable and reliable.

5. If you have problem during your project when using our product, we could arrange our engineer to help.

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: Need we stick membrane on SLR camera?

- The membrane can protect the LCD screen by preventing it from your sweat and unconscious stroke and touching of your nose when you use the camera. These actions are not benefit for the protection of the screen.

- Q: What are the advantages of using geomembranes in roof waterproofing?

- There are several advantages of using geomembranes in roof waterproofing. Firstly, geomembranes are highly durable and can withstand extreme weather conditions, making them ideal for long-term waterproofing solutions. Additionally, they are resistant to UV radiation, chemicals, and rot, ensuring their longevity. Geomembranes also provide a seamless and continuous waterproofing layer, eliminating the risk of leaks and water infiltration. Furthermore, they are lightweight and easy to install, reducing labor and installation costs. Lastly, geomembranes are flexible, allowing them to conform to any shape or size of the roof, ensuring a tight and secure fit.

- Q: What are the advantages using foil in construction?

- 1, insulation to reduce cooling costs: summer LLumar film can effectively block 79% of the sun's heat, greatly reducing the solar energy into the room, thereby reducing the cost of cooling the building. 2, thermal insulation to reduce heating costs in winter: the low-emissivity (LOW-E) film attached to the inner surface of the ordinary single glazing can reduce heat loss by 30%, reduce indoor heat loss, reduce winter heating costs. 3, blocking 99% of harmful UV rays: ultraviolet in solar radiation is mainly responsible for the damage and color fading of carpet, furniture, art paintings, curtains and many chemical fiber textile and the skin cancer. Energy-saving insulation film can block 99% of UV rays. 4, to reduce the harsh glare and add comfort: direct light at the office table or relaxing at home will lead to tiredness, eye fatigue and distraction. LLumar is a direct installation in the surface of the glazing product, it helps correct light intensity area and back positive zone temperature uneveness and dispersed glare, uncomfortable glare, making employees more comfortable interior, more efficient. 5, the formation of absolute privacy: mount LLumar reflective film may be formed absolute privacy, it can avoid the window watching, protection of private property is not exposed to activities and infringement. 6, improve safety explosion-proof performance: bonding together LLuamr armored dragon film can effectively break the glass, to reduce industrial accidents, earthquakes, typhoons, terrorism, wanton destruction, and property damage caused by theft and other acts against the people.

- Q: how to use the wall poster transfer membrane?

- Paste 1. Before you begin, make ready tools: Scissors, knives, card, or bank card. First, use the scissor to cut the blank part of the picture surroundings, and it is easy to paste; 2. the transfer film attached to the pattern, and card or bank card scraping back and forth repeatedly on the transfer film several times, so that pattern transfer film more good stick together, there will be no air bubbles attached after the wall; 3. remove the membrane which stick the picture from the bottom paper. if the picture is not pasted in the membrane, you can use the knife to cut it. When attached to a relatively large area pattern, the pattern may be turned to the back of paper and torn from a membrane and the picture; before going to the step 4, the first transfer film cut scrap pick a corner wall test wall performance, make sure the wall having no problem and then paste it. if the wall surface can be dropped powder or when tearing the membrane the wall paint may also be dropped down, please paste it after treatment; 4 texture case when the transfer film can first corner of the first stick to the wall then slowly slow will stick with transfer film along the downward direction of the pattern on the wall, followed by a card from the middle of the pattern repeated strokes of direction around, so better stick wall stickers on the wall; 5 transfer film time to tear away from the wall, try slower, you can while pressing the pattern transfer film tear off one side, the pattern must not be torn up together. Reminder: if you afraid it can't tear down after pasting, you can have a sticker affixed in place with hot water (40-50 degrees) or heating with a hair dryer blowing and tear, it is OK, if you fear to tear down with the glass as well as plastic (available heat water, alcohol, gasoline, kerosene) the stuff can be cleaned.

- Q: What specification of geomembrane is used by sewage treatment plant ?

- It should not be very high.

- Q: What is the purpose of a geomembrane liner?

- The purpose of a geomembrane liner is to provide a barrier and containment system for various applications, such as preventing the seepage or leakage of liquids, gases, or contaminants in construction projects, landfills, mining operations, agricultural ponds, and other environmental or industrial settings.

- Q: The working principle of the water film dust collector?

- Dusty gas from the lower part of the cylinder along the tangential introduction, spiral up, dust particles by the centrifugal force effect is parting, thrown to the inner wall of the cylinder body and the inner wall of the cylinder body is adsorbed water film activities, with the water in the end part of the cone, the dust discharge port of unloading

- Q: What are the aesthetic options for geomembranes?

- The aesthetic options for geomembranes are limited as they are primarily used for functional purposes rather than for aesthetic appeal. However, some geomembranes can be customized with various colors or patterns to blend with the surrounding environment or meet specific project requirements.

- Q: How do geomembranes contribute to the preservation of coastal ecosystems?

- Geomembranes contribute to the preservation of coastal ecosystems by acting as a barrier between the underlying soil and water bodies, preventing the contamination of surrounding water sources. They also help in controlling erosion and sedimentation, maintaining the stability of coastal areas. Additionally, geomembranes can be used for the construction of artificial wetlands or containment systems, promoting the growth of native plants and protecting vulnerable habitats. Overall, these protective barriers play a crucial role in safeguarding coastal ecosystems from pollution and degradation.

- Q: Are geomembranes resistant to oil and grease?

- Yes, geomembranes are generally resistant to oil and grease.

Send your message to us

Geomembrana Sodimac HDPE Geomembrane Liner for Landfill Capping

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords