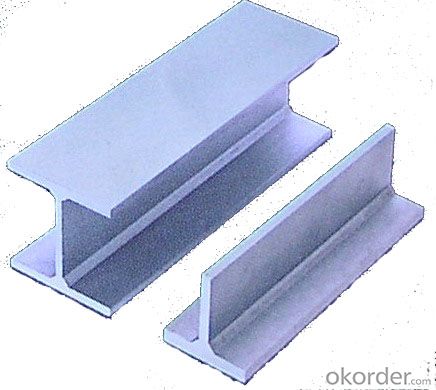

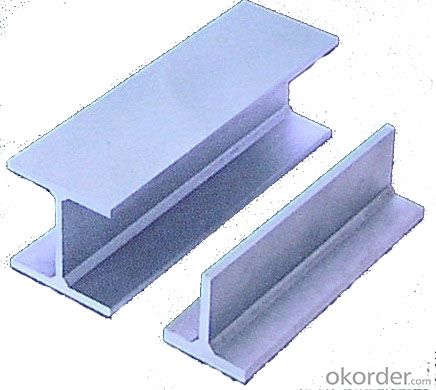

H Shape Steel Structure Steel Column Beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

H Shape Steel Structure Steel Column Beam

Quick Details

Place of Origin: | Hebei, China (Mainland) | Grade: | Q235B | Technique: | Hot Rolled |

Thickness: | 100*100*6*8-900*300*16*28mm | Application: | construction | Length: | 6-12m |

Standard: | JIS | Flange Width: | 100-900mm | Flange Thickness: | 6-20mm |

Web Width: | 100-500mm | Web Thickness: | 5-15mm |

Packaging & Delivery

Packaging Details: | in bulk or in bundle or as the customers' requirements. |

Delivery Detail: | 30-45 days or according to your requirements |

Specifications

1.100*100*6*8mm-900*300*16*28mm

2. Standard: GB,JIS,ASTM

3. Length: 6m/9m/12m

4. Origin: Tangshan, Hebei province

Description

1.Grade: Q235B, Q235, Q345B, SS400, A36

2.Standard: JIS/ ASTM/ GB/ BS

3.Length: 5.8m, 6m, 12m, or as the customers’ requirements.

4.Usage:

(1).used for the plant, high-rise building construction

(2).used for the bridge, shipment building

(3).used for lifting and transportation machinery, equipment manufacturing base building

(4).used for the support, foundation pile manufacturing

5. Payment terms: 30% tt in advance, the balance against the LC or the copy of BL.

6.Package: in bulk or in bundle.

Tech Datas

ACCORDING TO STANDARD: JIS G3192 OR GB/T11263-2005 | |||

H beam Section sizenma(mm) | Weight (kg/m) | ||

Height×Breadth | Web thichness | Flange thichness | |

100×100 | 6 | 8 | 16.9 |

125×125 | 6.5 | 9 | 23.6 |

150×150 | 7 | 10 | 31.1 |

175×175 | 7.5 | 11 | 40.4 |

200×200 | 8 | 12 | 49.9 |

250×250 | 9 | 14 | 71.8 |

300×300 | 10 | 15 | 93.0 |

300×300 | 15 | 15 | 105.0 |

350×350 | 12 | 19 | 134.9 |

400×400 | 13 | 21 | 171.7 |

148×100 | 6 | 9 | 20.7 |

194×150 | 6 | 9 | 29.9 |

244×175 | 7 | 11 | 43.6 |

294×200 | 8 | 12 | 55.8 |

340×250 | 9 | 14 | 78.1 |

390×300 | 10 | 16 | 104.6 |

440×300 | 11 | 18 | 120.8 |

482×300 | 11 | 15 | 110.8 |

488×300 | 11 | 18 | 124.9 |

582×300 | 12 | 17 | 132.8 |

588×300 | 12 | 20 | 147.0 |

100×50 | 5 | 7 | 9.3 |

125×60 | 6 | 8 | 13.1 |

150×75 | 5 | 7 | 14.0 |

175×90 | 5 | 8 | 18.0 |

198×99 | 4.5 | 7 | 17.8 |

200×100 | 5.5 | 8 | 20.9 |

248×124 | 5 | 8 | 25.1 |

250×125 | 6 | 9 | 29.0 |

298×149 | 5.5 | 8 | 32.0 |

300×150 | 6.5 | 9 | 36.7 |

346×174 | 6 | 9 | 41.2 |

350×175 | 7 | 11 | 49.4 |

396×199 | 7 | 11 | 56.1 |

400×200 | 8 | 13 | 65.4 |

446×199 | 8 | 12 | 65.1 |

450×200 | 9 | 14 | 74.9 |

496×199 | 9 | 14 | 77.9 |

500×200 | 10 | 16 | 88.1 |

596×199 | 10 | 15 | 92.4 |

600×200 | 11 | 17 | 103.4 |

700×300 | 13 | 24 | 181.8 |

800×300 | 14 | 26 | 206.8 |

900×300 | 16 | 28 | 240.1 |

Products Picture

- Q: Are Steel H-Beams resistant to warping or twisting?

- Steel H-Beams possess a high resistance to warping or twisting due to their unique design. The wide flange and vertical web of H-Beams contribute to their exceptional structural stability and ability to withstand bending forces. The symmetrical shape of H-Beams ensures the even distribution of loads, thereby minimizing the risk of warping or twisting. Moreover, H-Beams are commonly manufactured using high-strength steel, enhancing their ability to resist deformation when subjected to heavy loads or external forces. Consequently, Steel H-Beams are an optimal selection for a wide range of applications that demand robust and dependable structural components.

- Q: H steel compared with ordinary steel in the end what are the advantages and disadvantages?

- Structure: steel structure with high stability of hot-rolled H steel based, its scientific and reasonable structure, good flexibility and plasticity, high structure stability, suitable for bearing vibration and impact load of building structure, strong ability to resist natural disasters, especially suitable for some building structures with the earthquake. According to statistics, in the world of 7 or more devastating earthquake disaster, the H steel based steel structure damage to the smallest extent.

- Q: Can steel H-beams be used for bridges?

- Certainly! Bridges can indeed make use of steel H-beams. Due to their durability, versatility, and high strength-to-weight ratio, steel H-beams are frequently employed in the construction of bridges. These beams possess exceptional load-bearing capacity and can withstand heavy loads, making them suitable for a wide range of bridge designs and spans. Furthermore, steel H-beams exhibit resistance to corrosion, a vital characteristic for bridges that are exposed to environmental elements. The availability of these beams in various sizes and shapes enables engineers to design bridges that meet specific requirements. All in all, steel H-beams are a favored option when it comes to constructing bridges, thanks to their unwavering structural integrity and reliability.

- Q: Are steel H-beams suitable for modular construction?

- Modular construction can benefit greatly from the use of steel H-beams. These H-beams, also called I-beams or W-beams, are extensively utilized in the construction industry because of their high strength-to-weight ratio and versatility. The advantages of steel H-beams in modular construction are numerous. Firstly, their structural strength enables the construction of large, open spaces without the need for excessive support columns or walls. This feature is particularly valuable in modular buildings that require flexibility in interior layout and design. Moreover, H-beams are lightweight in relation to their load-bearing capacity, which makes them easier to transport and handle during the modular construction process. Their prefabricated nature also reduces on-site labor and time, resulting in quicker construction timelines and cost savings. Additionally, steel H-beams exhibit excellent durability and resistance to environmental factors such as fire, corrosion, and pests. Therefore, modular buildings constructed with H-beams have a longer lifespan and require minimal maintenance. Lastly, steel H-beams are easily recyclable, making them an environmentally sustainable choice for modular construction. Their high scrap value and recyclability contribute to minimizing the environmental impact of construction projects. In conclusion, steel H-beams are highly suitable for modular construction due to their structural strength, lightweight nature, durability, and sustainability. They enable the creation of flexible and spacious modular buildings while reducing construction time and costs.

- Q: How do you calculate the plastic moment capacity of steel H-beams?

- The plastic moment capacity of a steel H-beam can be calculated using the formula M = Fy * Z, where M is the plastic moment capacity, Fy is the yield strength of the steel, and Z is the plastic section modulus of the H-beam. The plastic section modulus can be determined by dividing the moment of inertia of the beam about its neutral axis by the distance from the neutral axis to the extreme fiber.

- Q: What are the different connection types for steel H-beams?

- The different connection types for steel H-beams include welded connections, bolted connections, and riveted connections.

- Q: Can Steel H-Beams be used in modular or prefabricated construction?

- Modular or prefabricated construction can utilize Steel H-Beams effectively. These H-Beams are frequently employed in construction projects owing to their robustness, endurance, and versatility. They offer exceptional structural support and can endure substantial loads, making them highly suitable for modular or prefabricated construction that necessitates swift and efficient assembly. In these construction methods, Steel H-Beams are often used as columns, beams, or trusses, providing a sturdy and stable framework for the modular components. Moreover, their standardized sizes and uniform shape make them effortless to transport and assemble on-site, further augmenting the efficiency of modular or prefabricated construction. In conclusion, due to their strength, adaptability, and ease of installation, Steel H-Beams are widely favored in this type of construction.

- Q: Can Steel H-Beams be used in hospital or healthcare facility construction?

- Steel H-Beams are suitable for use in hospital or healthcare facility construction. Due to their strength, durability, and load-bearing capacity, they are widely used in construction projects. In healthcare facilities, where the safety of patients and staff is paramount, steel beams can provide structural integrity and support for the building. Moreover, steel beams can be easily fabricated and installed, making them a popular option in construction projects. Additionally, steel beams are resistant to fire, pests, and rot, which are crucial considerations for maintaining a safe and hygienic environment in healthcare facilities. In conclusion, the use of Steel H-Beams in hospital or healthcare facility construction is both reliable and practical.

- Q: What is the height of the four fillet welds in H steel submerged arc welding, such as H600*300*6*12?

- The plate thickness is 6 and 12 respectively, and the fillet weld value is the same as the thickness of the thin plate (when the design does not require)

- Q: What are the fire protection requirements for steel H-beams?

- Various factors, such as the type of building, occupancy, and fire safety codes and regulations, influence the fire protection requirements for steel H-beams. In general, it is necessary to enhance the structural integrity of steel H-beams during a fire by providing fire protection. The main objective of fire protection for steel H-beams is to prevent the steel from reaching its critical temperature, which can weaken the beams. To achieve this, measures are taken to delay the heating of the steel and prevent premature failure. One commonly used method of fire protection for steel H-beams is applying fire-resistant coatings. These coatings are specifically designed to insulate the steel and create a barrier against the fire, slowing down the rise in temperature. They are applied to the exposed surfaces of the H-beams, providing a protective layer that reduces the transfer of heat to the steel. Another method of fire protection for steel H-beams involves encasing them in fire-resistant materials. This can be done by enclosing the H-beams within gypsum boards or concrete, which act as a physical barrier against the fire. The encasement shields the steel, preventing direct exposure to the flames and heat. The fire protection requirements for steel H-beams vary depending on the specific fire safety codes and regulations in place. These requirements may specify the type, thickness, and duration of fire resistance needed for the coatings or encasement. To determine the specific fire protection requirements for steel H-beams in a particular building or project, it is important to consult with a qualified fire protection engineer or local fire safety authorities. Complying with these requirements ensures the safety and structural stability of the building in case of a fire.

Send your message to us

H Shape Steel Structure Steel Column Beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords