Structural Steel H-Beam;

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

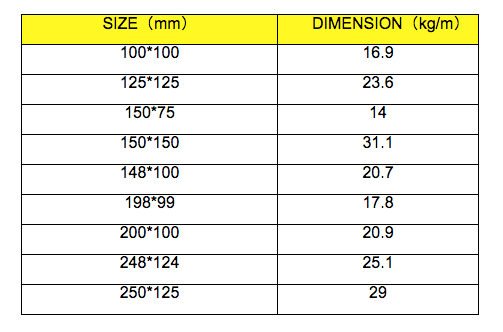

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Structural Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: What are the different types of steel H-beam connections used in seismic design?

- There are several types of steel H-beam connections used in seismic design, including bolted end plate connections, welded end plate connections, and moment-resisting connections. Bolted end plate connections involve attaching a steel plate to the ends of the beams using bolts. Welded end plate connections, on the other hand, involve welding the steel plates to the ends of the beams. Moment-resisting connections are designed to resist rotational forces and are typically used in buildings subjected to high seismic loads. These connections are more complex and involve welding or bolting additional steel plates and angles to the beams to increase their strength and stiffness.

- Q: Are steel H-beams resistant to seismic activity?

- Steel H-beams are generally known to be resistant to seismic activity. This is because steel is a highly durable and strong material, making it ideal for withstanding the forces generated during seismic events. H-beams are specifically designed to evenly distribute the load along their length, offering excellent structural support against vertical and lateral movements. Furthermore, steel H-beams are commonly used in earthquake-prone regions due to their superior ability to withstand seismic forces. The flexibility and elasticity of steel allow it to absorb and dissipate seismic energy, minimizing damage caused by ground shaking. Additionally, steel H-beams are often interconnected with other structural elements, such as columns and braces, forming a seismic-resistant system that effectively absorbs and redirects seismic forces. It is important to note, however, that the seismic resistance of steel H-beams can vary depending on factors such as design, construction quality, and adherence to building codes and regulations. To ensure that steel H-beams are appropriately designed and installed to withstand the specific seismic conditions of an area, proper engineering and construction practices must be followed. In conclusion, when designed and constructed properly, steel H-beams provide excellent resistance to seismic activity and are widely utilized in earthquake-resistant building structures.

- Q: Can steel H-beams be used in educational institutions and schools?

- Yes, steel H-beams can be used in educational institutions and schools. Steel H-beams are commonly used in construction for their strength, durability, and load-bearing capabilities. They are often used in the construction of bridges, high-rise buildings, and other large structures. In educational institutions and schools, steel H-beams can be used for various purposes such as supporting the framework of buildings, constructing gymnasiums and auditoriums, creating outdoor structures like canopies or walkways, and even for educational purposes in engineering or construction-related courses. The use of steel H-beams in educational institutions ensures the safety and stability of the structures, providing a conducive environment for learning and activities.

- Q: What are the different grades of steel used for manufacturing H-beams?

- Manufacturers commonly use different grades of steel to produce H-beams, each having distinct chemical compositions and mechanical properties that determine their suitability for various applications. Some commonly employed grades are as follows: 1. ASTM A36, a widely used low carbon steel grade, is highly favored for general structural purposes due to its exceptional weldability and machinability. 2. ASTM A572 exhibits greater strength and superior corrosion resistance compared to A36. It finds extensive use in applications requiring higher load-bearing capabilities, such as heavy construction and bridge building. 3. ASTM A992 is specially designed for wide-flange shapes like H-beams. It offers increased yield strength and enhanced ductility when compared to A36, making it ideal for structural applications that demand optimal performance. 4. ASTM A588 is renowned for its exceptional resistance to atmospheric corrosion. It is frequently employed in outdoor applications, including bridges and buildings located in harsh environments. 5. ASTM A709 primarily serves the purpose of constructing bridges and other infrastructure projects. With its high tensile strength, excellent toughness, and improved weldability, it is highly suitable for manufacturing H-beams in such applications. It is crucial to note that the selection of a specific steel grade relies on project requirements, including load-bearing capacity, environmental conditions, and other relevant factors. Seeking advice from a structural engineer or steel supplier can aid in determining the most appropriate grade for a given application.

- Q: What are the different design codes and standards for steel H-beams?

- Some of the different design codes and standards for steel H-beams include the American Institute of Steel Construction (AISC) 360, Eurocode 3, British Standards (BS) 5950, and the Canadian Standards Association (CSA) S16. These codes and standards provide guidelines and specifications for the design, fabrication, and construction of steel H-beams, ensuring structural integrity and safety.

- Q: What are the different types of steel H-beams?

- Different types of steel H-beams are available for specific applications and structural requirements. The following are the most common options: 1. W-beams, known as wide flange beams, are extensively used H-beams. They offer increased stability and support due to their wide flange. They are widely utilized in construction and are offered in various sizes and weights. 2. S-beams, also referred to as American Standard beams, have a narrower flange compared to wide flange beams. They are lighter and more cost-effective, making them suitable for smaller-scale applications or when weight is a concern. 3. European Standard beams (HEA, HEB, HEM) are designed according to European standards. They have different cross-sectional shapes, such as I-shaped or H-shaped profiles, and are commonly used in Europe for structural and engineering projects. 4. JIS beams, or Japanese Standard beams, are designed based on Japanese industrial standards. They are extensively used in Japan and other Asian countries and have distinct dimensions and specifications compared to other standards. 5. In addition to the standard types, specialized H-beams are available for specific applications. These include bearing piles (used in foundation construction), sheet pile beams (used in retaining walls or flood protection), and composite beams (consisting of a combination of materials for enhanced strength or unique properties). When selecting the type of steel H-beam for your project, it is essential to consider the specific requirements, such as load-bearing capacity, structural integrity, and compatibility with other construction materials. Consulting with a structural engineer or a steel supplier can assist in determining the most suitable H-beam for your specific needs.

- Q: Can steel H-beams be used for retaining walls?

- Indeed, steel H-beams are suitable for the purpose of retaining walls. In construction projects, they are frequently employed owing to their remarkable strength and durability. These beams possess the ability to withstand substantial loads and offer exceptional support to retaining walls. The H-shape design of the beam facilitates superior weight distribution and stability, rendering it an appropriate option for retaining walls that must withstand pressure from soil or other substances. Moreover, the installation of steel H-beams is effortless, and they boast a lengthy lifespan, which explains their widespread use in diverse construction applications, including retaining walls.

- Q: How do steel H-beams perform in areas with high wind loads?

- In areas with high wind loads, steel H-beams exhibit exceptional performance. The H-shaped design of these beams imparts remarkable strength and stability, rendering them highly impervious to lateral forces generated by powerful winds. The structural integrity of steel H-beams facilitates the uniform distribution of wind load throughout the entire beam, thereby minimizing the likelihood of failure or deformation. Moreover, steel possesses enduring qualities and pliability, further augmenting its efficacy in regions prone to strong winds. The elevated tensile strength of steel empowers it to endure the force exerted by powerful winds, providing outstanding resistance against bending or buckling. All in all, steel H-beams represent an ideal selection for construction projects in areas with high wind loads, as they furnish dependable and enduring support to structures in such circumstances.

- Q: Can Steel H-Beams be used in airport or transportation terminal construction?

- Steel H-Beams are indeed applicable for airport or transportation terminal construction. They are commonly utilized in construction ventures that necessitate structural reinforcement, such as airports and transportation terminals. These beams possess exceptional load-bearing capabilities and can endure heavy loads, rendering them suitable for erecting extensive structures like airports and terminals. Moreover, they are recognized for their robustness and extended lifespan, which are pivotal for infrastructure projects. Furthermore, Steel H-Beams can be effortlessly produced and incorporated, thereby facilitating efficient construction procedures. Overall, Steel H-Beams are a favored option in airport and transportation terminal construction owing to their potency, longevity, and easy installation.

- Q: Can steel H-beams be used in the construction of medical facilities or hospitals?

- Yes, steel H-beams can be used in the construction of medical facilities or hospitals. Steel H-beams are commonly used in construction due to their structural strength and versatility. They provide excellent load-bearing capabilities and can withstand heavy loads, making them suitable for constructing large and complex structures like hospitals. Additionally, steel H-beams are durable and resistant to fire and pests, which are crucial factors for maintaining the safety and functionality of medical facilities. The use of steel H-beams in hospital construction also allows for flexible and open floor plans, facilitating the incorporation of various medical equipment and the adaptation of spaces to meet evolving healthcare needs. Overall, steel H-beams offer numerous advantages in terms of strength, durability, safety, and adaptability, making them a suitable choice for the construction of medical facilities or hospitals.

Send your message to us

Structural Steel H-Beam;

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords