Gypsum Board For Ceiling 15mm High Quality High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

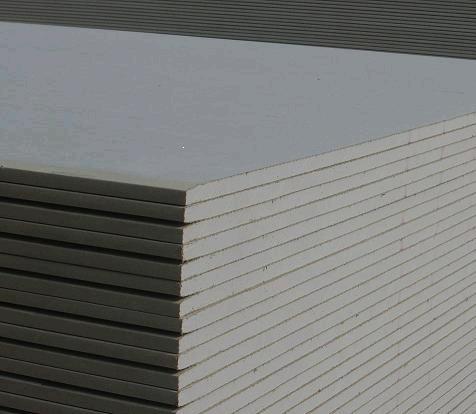

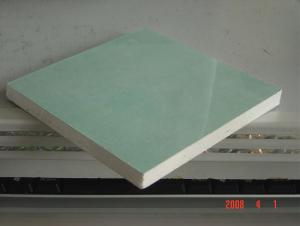

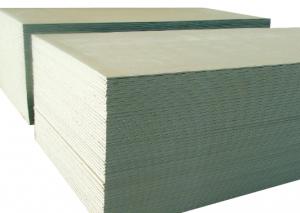

Gypsum board, also known as Drywall/Plaster board, is a panel used typically in interior construction to form a wall or ceiling. The panel has a gypsum core and is faced with heavy paper on both sides, one side specially treated for finishing. Also Known As:Gyp Board, Gypsum Board, Drywall, Sheetrock, Wall Board.

Product Applications:

Mainly used in those places with highg-rade decorationwhere strict acoustic environment is crucial,

such as theater, concert hall, museum, library, hearing room, gallery, auction house, gymnasium,

lecture hall, multifunctional hall, hotel lobby, hospital, shopping mall, piano practice room,

conference room, studio, recording room, KTV room, bar, industrial workshop, machine room, etc

Product Advantages:

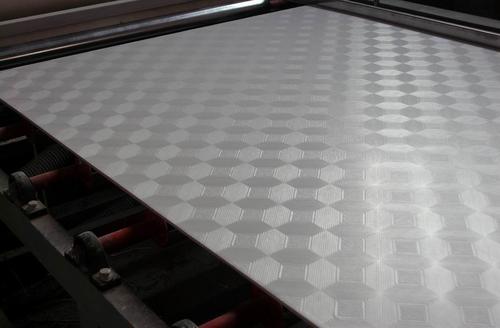

1) Environmental, dust and moisture resistant, easy to clean.

2) Commercial & good for decorative, popular designed patterns for your choosing.

3) Flexible suspension system makes each ceiling tile easily installed and disconnected

4) Easy to match lamps or other ceiling parts.

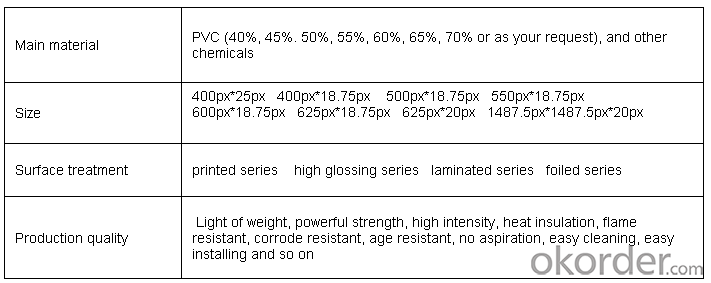

Main Product Features:

MATERIAL:GYPSUM BOARD

SURFACE:PAPER FACED

EDGE:SQUARE,TARERED

DENSITY:AS PER GB/T9775-1999

BREAKING STRENGTH:AS PER GB/T9775-1999

ANTI-FIRE FUNCTION:<30 MINS AS PER GB8624-1997

COMBUSTION PERFORMANCE:NON-COMBUSTIBLE MATERIAL

SIZE TOLERANCE:LENGTH/WIDTH<+-2.0MM

MOISTURE CONTENT: <2%

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

Images:

- Q: I have some plasterers doing some work in my kithchen at the moment, and i've just had the kitchen damp proffed with injection and a roll of bitchumen membrane up to approx a metre high all round the kitchen. The plasterers have told me that the dry wall won't stick to the bitchumen membrane, so have suggested putting up a stud frame all round the kitched so that they can screw the plasterboards to the new stud frame!! Is this really necessary?? Does plasterboarding with dry wall adhesive really not stick to sheet roll's of bitchumen?? Also, they have also told me that you can't drywall with foil back boards as the adhesive won't stick to the foil....is this also true???Many thanks

- plasterboard or sheetrock is not glued to any backing. It must be nailed or screwed onto a frame. never heard of the adhesive way.

- Q: Can you wipe the cement mortar on the gypsum board?

- Can not. Need to add a layer of cement board in the gypsum board, and then you can operate the tile.

- Q: Gypsum board light steel keel ceiling method

- This is determined according to the specifications of the fire board, the higher the price the more expensive, and the quality and strength is also very important, as well as its water resistance, fire and water balance, such a fire board to ensure the quality of construction works, Seoul Building Materials Co., Ltd. was established in 1982 is an integrated ceiling, partition system one of the earliest series of domestic R & D company, set light steel keel, gypsum board, mineral wool acoustic board, paint keel, calcium silicate board, fiber cement Pressure plate and other products specializing in the production and processing of the company, has a complete and scientific quality management system,

- Q: can you put a punch bag on plasterboard?

- Obviously you must mean plasterboard on brick? I am not certain but i am guessing this will cause cracks around the wall bracket and after time make cracks down the wall. Best answer if you could please.

- Q: Gypsum board ceiling can be installed sound what Mody

- You refer to the gypsum board hanging speakers, then to find hanging bars (ceiling of the keel), or additional hanging bars, it is not on the wall!

- Q: What does Plasterboard look like?

- Its a wooden window sill, plasterboard is what is on the wall bellow it, asbestos (to my knowledge) was never used as window sills, nor was used in place of plaster in old houses, or plaster board in new houses, it was used as roofing material on industrial buildings,

- Q: so I can have a wall basket

- It is OK if you use a proper plasterboard fixture, the ones with wings, and not add too much weight to the basket. Factor in the weight of the water you will have to use for the plants as well.

- Q: I have just had a new Combi boiler fitted and have had the old back boiler and fire disconected. The fire place in which the backboiler and fire fitted in is 18 inches deep and 4 1/2 ft wide and is plasterboard on a wooden frame. There is a thermalite chanell that the flue pipe runs up. What we would like to do is rip the plasterboard section out to open up the room more, I am not sure about whether it is safe to remover the thermalite bricks or not???

- Before you start make sure you have plenty dust sheets,to cover up furniture and carpets.Once that`s don`t you can tackle the job in hand.Lift up the hearth first,this should come up easily.Next channel around the fireplace,once that`s done there should be screws on either side of the surround.Removing that the surround should come away from the wall.Next is to chop away the fire brick and rubble that`s behind it,once that`s don`t you should be left with a hollow opening.You can either brick it up or board it which is easy for you,but make sure you put a air vent in there,which would help the chimney to breath and stop dampness in the chimney flue.I hope this is on use to you.

- Q: there are a lot of mice in my area, my cats are forever catching and killing them. my neighbour has had them inside her house (she has no cats). last night both my cats were upstairs, staring at the wall. i put them out when i went to bed and then heard all this scratching in the wall behind my bed. its a plasterboard wall filled with insulation and doesnt lead anywhere else, unless they've chewed their way thru the ceiling or chipboard floor. why on earth wud mice come in when they cant get food??? and how the heck do i get them out without making holes in the wall?

- in case you seize them and can't preserve them stumble on a no kill take care of on your section. In northern CA we've 9 Lives they take all of them, from feral to toddler kittens and each and every thing in between. They by no ability positioned them down and save them until eventually eventually followed. Now lower back to the area of warm temperature. I had a feral years in the past. I took an previous shaped laundry basket, positioned a pillow in it & positioned previous sea coast towels on suitable of the pillow and up the perimeters of the basket. She slept each and every evening even as it change into chilly, on my coated the front porch. I were given a tremendous used field became it on its section and positioned the basket contained in the field as wintry climate winds approached. She looked as if it would love it. strong success.

Send your message to us

Gypsum Board For Ceiling 15mm High Quality High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords