Aluminum PE Outdoor Roofing Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PE Aluminium Composite Panel for Outdoor Roofing Description

PE Aluminium Composite Panel for Outdoor Roofing is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of PE Aluminium Composite Panel for Outdoor Roofing

PE Aluminium Composite Panel for Outdoor Roofing | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of PE Aluminium Composite Panel for Outdoor Roofing

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of PE Aluminium Composite Panel for Outdoor Roofing

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of PE Aluminium Composite Panel for Outdoor Roofing

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

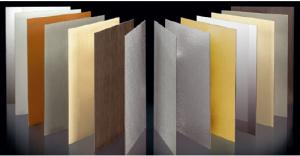

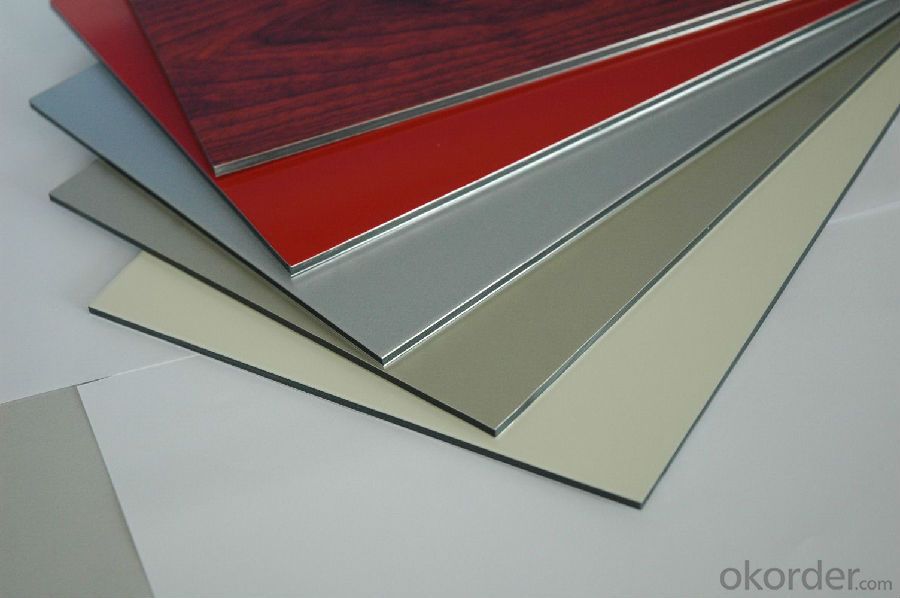

6. Image of PE Aluminium Composite Panel for Outdoor Roofing

7. Package and shipping of PE Aluminium Composite Panel for Outdoor Roofing

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for a comparison between aluminum and other metals, highlighting their distinct properties and characteristics.

- <p>Aluminum is a lightweight, corrosion-resistant metal with a low density, making it ideal for applications requiring strength without excessive weight. It is also a good conductor of heat and electricity. Unlike other metals like iron or copper, aluminum is not magnetic and has a lower melting point. It is also more abundant and cheaper to produce than many other metals, which makes it widely used in industries such as construction, transportation, and packaging. Aluminum's reactivity means it forms a protective oxide layer when exposed to air, which prevents further corrosion. In contrast, metals like stainless steel offer greater strength and resistance to corrosion, while copper has superior electrical conductivity. Each metal has its unique properties that make it suitable for specific applications.</p>

- Q: Is it possible to join aluminum pieces together using welding techniques?

- <p>Yes, aluminum can be welded. Welding aluminum is a common practice in various industries due to its lightweight and corrosion-resistant properties. Techniques such as Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Shielded Metal Arc Welding (SMAW) are used. However, aluminum welding requires specific precautions, such as using a clean, dry surface and a proper shielding gas to prevent oxidation, as aluminum readily reacts with oxygen.</p>

- Q: Explain the impact of using recycled aluminum on the environment.

- <p>Using recycled aluminum significantly reduces our environmental footprint. It requires only 5% of the energy needed to produce new aluminum from raw materials, thus conserving energy. Additionally, recycling aluminum reduces greenhouse gas emissions by up to 95% compared to aluminum production from bauxite ore. This lowers air pollution and helps combat climate change. Moreover, recycling aluminum conserves natural resources and reduces the need for mining, which has its own set of environmental impacts, including habitat destruction and water pollution. Overall, recycling aluminum is a sustainable practice that benefits the environment by reducing energy consumption, emissions, and resource extraction.</p>

- Q: What are the positive environmental impacts of utilizing recycled aluminum over newly produced aluminum?

- <p>Using recycled aluminum has several environmental benefits. It conserves natural resources by reducing the need for bauxite mining, which is the primary source of aluminum. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials, which can lead to a substantial reduction in greenhouse gas emissions. Additionally, recycling aluminum helps in reducing landfill waste, as it diverts used aluminum products from landfills. Moreover, it decreases the environmental impact associated with the production process, such as water pollution and habitat destruction. Overall, recycling aluminum is a more sustainable practice that contributes to a lower carbon footprint and a healthier environment.</p>

- Q: Besides other special pots, can other aluminum pots be used?

- Electromagnetic stove pot must be metal pot with magnetic and non-magnetic stainless steel, aluminum pot can not be used.

- Q: This question asks for the various applications or purposes of aluminum alloys.

- <p>Aluminum alloys are used in a wide range of applications due to their lightweight, high strength, and corrosion resistance. They are commonly used in the automotive industry for vehicle construction to reduce weight and improve fuel efficiency. In the aerospace industry, they are essential for constructing aircraft and spacecraft. Other applications include construction materials, such as window frames and roofing, and in consumer goods like beverage cans and electronic devices. Aluminum alloys are also utilized in machinery and transportation equipment, sports equipment, and various engineering components where a combination of strength, durability, and low weight is required.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum foil in the culinary process.

- <p>Aluminum foil offers several advantages in cooking, such as easy clean-up, even heat distribution, and the ability to create a seal for steaming or baking. It's also versatile, being suitable for both roasting and wrapping food for baking. However, there are disadvantages, including potential health concerns due to the leaching of aluminum into food, especially at high temperatures. Additionally, foil can tear easily, and it's not suitable for non-stick surfaces or use under broilers. Environmentally, it's not biodegradable and contributes to waste, which is a significant disadvantage.</p>

- Q: This question asks about the typical applications of aluminum pipes in various industries and settings.

- <p>Aluminum pipes are commonly used in a variety of applications due to their lightweight, corrosion resistance, and high thermal conductivity. They are extensively used in the automotive industry for parts like radiators and heat exchangers. In construction, aluminum pipes are utilized for heating, ventilation, and air conditioning (HVAC) systems. They are also used in the beverage industry for conveying and cooling liquids, as well as in the aerospace industry for fuel and hydraulic lines due to their strength-to-weight ratio. Additionally, aluminum pipes are found in industrial settings for compressed air and gas lines, and in marine applications for fuel and water systems.</p>

- Q: This question asks to outline the various environmental effects that result from the production of aluminum.

- <p>Aluminum production has several environmental impacts. It is energy-intensive, leading to high greenhouse gas emissions, primarily CO2, contributing to climate change. The process also generates toxic byproducts such as fluorides and cyanides, which can contaminate soil and water. Biodiversity is affected due to habitat destruction from mining activities. Additionally, aluminum production consumes significant amounts of water, which can strain local water resources. The industry also contributes to air pollution through the release of particulate matter and other pollutants. Overall, aluminum production poses a significant environmental challenge that requires sustainable practices and technologies to mitigate its impacts.</p>

- Q: Explain the interaction between aluminum and acids.

- <p>Aluminum reacts with acids to produce hydrogen gas and a salt of the acid. This reaction is a type of single displacement reaction where aluminum displaces hydrogen from the acid. The general reaction can be represented as 2Al + 6HCl 鈫?2AlCl鈧?+ 3H鈧? The aluminum metal is oxidized to form aluminum ions, while the hydrogen ions from the acid are reduced to form hydrogen gas. The specific products and reaction rates can vary depending on the type of acid and the conditions of the reaction.</p>

Send your message to us

Aluminum PE Outdoor Roofing Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords