Ground Cover or Polypropylene Woven Geotextile for Agriculture

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

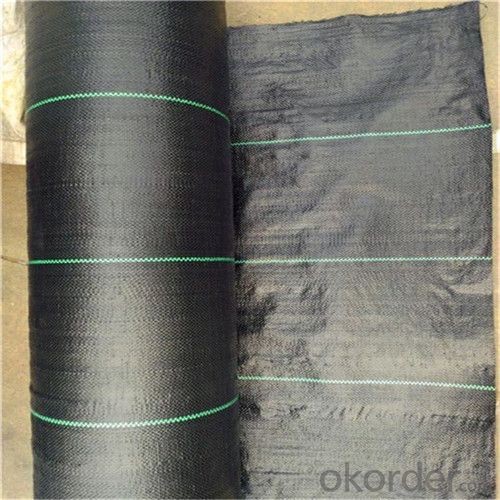

Polypropylene Woven Geotextile Description

Polypropylene woven geotextile is made from polypropylene flit yarn on circular loom and flat loom, manufactured using highly specialized fiber technology and processes to produce a range of versatile woven geotextiles.

Polypropylene Woven Geotextile Specification

Weight: 75gsm-400gsm

Width: 1m -6m

Length:as request

Color: white, black, green, as request

Strip: every 12", as request

Polypropylene Woven Geotextile Property:

1) Light weight, high strength, low elongation, easy to construct.

2) Reinforcement, separation, drainage and filtration, fencing function.

Polypropylene Woven Geotextile Application

Railways, highways, sport fields, earthwork projects, tunnels, coal mines, walls and slopes, environmental protection and so on.

Packaging & Shipping

Packing: Plastic film or woven bag;

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles effective in preventing soil contamination?

- Yes, geotextiles are effective in preventing soil contamination. They act as a barrier between the soil and potential contaminants, such as chemicals or pollutants, preventing them from leaching into the soil. Geotextiles also help in stabilizing the soil, reducing erosion, and promoting proper drainage. Overall, they play a crucial role in protecting soil quality and preventing contamination.

- Q: Are geotextiles suitable for use in waste containment systems?

- Yes, geotextiles are suitable for use in waste containment systems. They are commonly used as liners or covers in landfills and other waste management facilities to prevent the migration of contaminants and control leachate. Geotextiles provide filtration, separation, and reinforcement properties that enhance the overall performance and longevity of waste containment systems.

- Q: What are the factors to consider when selecting geotextiles for landfill applications?

- When selecting geotextiles for landfill applications, there are several factors that need to be considered. These include the strength and durability of the geotextile, its filtration and drainage capabilities, chemical resistance, and its ability to withstand long-term exposure to environmental conditions such as moisture and ultraviolet radiation. Additionally, factors such as cost, availability, and compliance with regulatory requirements should also be taken into account.

- Q: Geotechnical construction of the weather when there is any requirement

- Geotechnical construction of the weather when there is any requirement

- Q: What are the specifications for geotextiles in pond liner projects?

- The specifications for geotextiles in pond liner projects typically include factors such as weight, tensile strength, permeability, and puncture resistance. The geotextile should be heavy enough to provide sufficient protection against punctures and tears, while also allowing for water to pass through and prevent buildup on the liner. It should have high tensile strength to withstand the stresses of installation and long-term use. Additionally, the geotextile should meet industry standards and regulations for quality and durability in pond liner applications.

- Q: Geotextile a square meter how much money

- I professional production, ranging from 3-10 yuan

- Q: What is the size of the filament geotextile? What are the characteristics of the application?

- What is the size of the filament geotextile? What are the characteristics of the application?

- Q: Specification for Lap Length of Geotextile with Two Cloth

- 20cm I specialize in producing geotextile materials

- Q: Are geotextiles suitable for use in mining tailings containment?

- Yes, geotextiles are suitable for use in mining tailings containment. Geotextiles offer excellent filtration properties, high tensile strength, and durability, making them effective in preventing soil erosion and controlling water flow within tailings containment areas. They can also aid in the separation of different layers of tailings, improving the stability and overall performance of the containment system.

Send your message to us

Ground Cover or Polypropylene Woven Geotextile for Agriculture

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords