Green Aluminum Coil - Coated and Stucco Embossed Aluminium Coils Alloy 3003

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

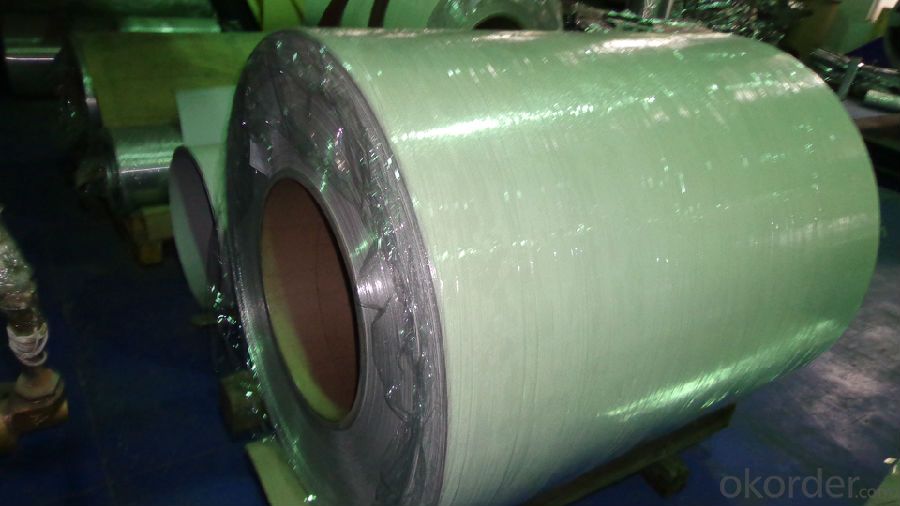

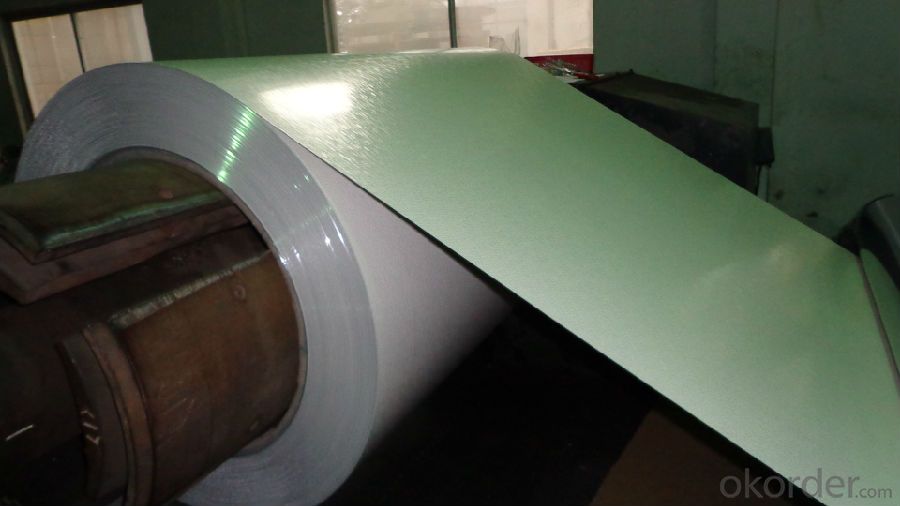

1.Structure of Coated and Stucco Embossed Aluminium Coils Alloy 3003

Alloy 3003, H44 is widely used in cold storages, refrigerators, ice-boxes, etc after being coated and stucco embossed.

We normally use 3003, H44 as base coils. Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of Coated and Stucco Embossed Aluminium Coils 3003

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. Coated and Stucco Embossed Aluminium Coils 3003 Images

4. Specification of Coated and Stucco Embossed Aluminium Coils 3003

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum coils be used in the production of electrical cables?

- Yes, aluminum coils can be used in the production of electrical cables. Aluminum is a widely used material in the electrical industry due to its excellent electrical conductivity and lightweight properties. Aluminum coils are commonly used to manufacture power cables, building wires, and other electrical conductors. They have been proven to be a cost-effective alternative to copper coils, which are more expensive but possess higher electrical conductivity. The use of aluminum coils in electrical cables can help reduce the overall weight of the cables, making them easier to install and handle. Additionally, aluminum coils have good corrosion resistance, making them suitable for outdoor and underground applications. However, it is important to note that aluminum has a lower tensile strength compared to copper, so proper design considerations and installation techniques must be taken into account to ensure the longevity and reliability of aluminum-based electrical cables.

- Q: Is it safe and effective to use an oven to heat an aluminum coil?

- <p>Yes, you can use an oven to heat an aluminum coil, but with caution. Aluminum has a high melting point and can withstand high temperatures, making it suitable for heating in an oven. However, it's crucial to ensure that the coil is clean and free of any non-stick coatings or residues that could produce toxic fumes when heated. Additionally, monitor the temperature and duration of heating to avoid overheating, which might cause the coil to warp or degrade. Always follow safety guidelines and manufacturer's instructions for your specific oven and aluminum coil.</p>

- Q: What are the different sizes available for aluminum coils?

- Aluminum coils are available in various sizes to meet the diverse needs of different industries and applications. The sizes of aluminum coils can vary depending on factors such as the intended use, manufacturing process, and customer requirements. Generally, aluminum coils are available in a range of thicknesses, typically ranging from 0.2mm to 8mm. The width of aluminum coils can vary from as narrow as a few inches to more than 60 inches. The length of aluminum coils can be customized, but standard lengths are often around 1000mm to 6000mm. The specific sizes available for aluminum coils may also depend on the manufacturing capabilities of the supplier or manufacturer. Some suppliers may offer a wide variety of sizes to cater to different customer demands, while others may have a more limited range of sizes. It is important to note that the availability of specific sizes may also be subject to minimum order quantities or lead times. Therefore, it is advisable to consult with the supplier or manufacturer to inquire about the specific sizes available and any limitations or requirements that may apply. Overall, the different sizes available for aluminum coils provide flexibility for customers to choose the most suitable dimensions for their specific applications and requirements.

- Q: What is the typical warranty period for aluminum coils?

- The typical warranty period for aluminum coils varies depending on the manufacturer and the specific application. However, it is common to find warranties ranging from 5 to 10 years for residential applications, while commercial warranties can extend up to 20 years or more. It is recommended to check with the manufacturer or supplier for the exact warranty details for specific aluminum coil products.

- Q: Are there any limitations on the embossing of aluminum coils?

- Yes, there are some limitations on the embossing of aluminum coils. One limitation is the thickness of the aluminum coil. Embossing is typically more difficult on thicker coils, as they require more force to achieve the desired pattern. Additionally, the embossing process may cause the coil to stretch or distort, particularly if the thickness is already close to the upper limit for embossing. Another limitation is the complexity of the embossing design. Intricate or detailed patterns may be more challenging to achieve on aluminum coils, especially if they have a lower gauge or thickness. The embossing process may not be able to accurately replicate intricate designs, resulting in a less defined or distorted pattern. The size of the aluminum coil can also pose a limitation. If the coil is too large, it may be difficult to emboss evenly across the entire surface. This can result in inconsistencies in the embossed pattern or uneven pressure being applied to the coil during the embossing process. Lastly, the type and quality of the aluminum can limit the embossing capabilities. Different alloys or grades of aluminum may have varying levels of malleability and resistance to embossing. Some alloys may be more prone to cracking or deforming during the embossing process, limiting the types of patterns that can be achieved. Overall, while embossing can be done on aluminum coils, the thickness, complexity of the design, size, and quality of the aluminum can all impact the limitations of the embossing process. It is important to consider these factors when embossing aluminum coils to ensure the desired results are achieved.

- Q: Are aluminum pie pans and aluminum foil considered green products? They are most certainly recyclable. Thanks.?

- Aluminium does not need to be clean to be recycled! You have to take aluminium to above 1000°C to melt and recycle it, and at that temperature any food scraps or similar substances on the aluminium would simply turn into carbon dioxide and water vapour and disappear!

- Q: Are there any limitations to the minimum coil length of aluminum coils?

- The minimum coil length of aluminum coils has certain limitations. These limitations are influenced by factors such as the manufacturing process, equipment capabilities, and the intended use of the coils. One limitation arises from the size and capacity of the manufacturing equipment. To ensure smooth operation and prevent damage during manufacturing, most coil production lines have a minimum length requirement. If the coil is too short, it may not be processed or handled properly by the equipment, resulting in production issues or defects. Another limitation is determined by the intended use of the coils. Certain applications may demand a minimum coil length to meet specific requirements or ensure optimal performance. For instance, industries like construction or automotive often utilize coils to create components or structures with precise length specifications. In such cases, the minimum coil length is determined by the end product's specifications. Furthermore, handling and transportation considerations also impact the determination of the minimum coil length. Coils that are too short might pose challenges in terms of handling, transportation, and storage, making them impractical or cost-inefficient. In conclusion, the minimum coil length of aluminum coils is constrained by manufacturing equipment capabilities, intended use, and practicality in terms of handling and transportation. These limitations guarantee efficient production processes, adherence to product specifications, and practicality within the overall supply chain.

- Q: What is the typical thermal expansion coefficient for aluminum coils?

- The typical thermal expansion coefficient for aluminum coils is around 23.1 x 10^-6 per degree Celsius (or 23.1 x 10^-6/°C). This coefficient represents the change in length of an aluminum coil per degree Celsius increase in temperature. It is important to note that this value may vary slightly depending on the specific alloy and composition of the aluminum coil.

- Q: Im trying to make a aluminum ring. I want it to be rock hard. PLZZAnswers that work get best answer

- First off, use the right alloy. Making the right alloys yourself is a recipe for disaster so it is best to buy them. There are a number of inexpensive alloys of aluminum that can be hard enough to be used as a ring. 5000 series, 6000 series and 7000 series are all pretty hard. If the alloy has a T in front of it, that means you can temper it by heating it then cooling it at a given rate (usually fast). To make the surface just a little bit harder, you can then anodize it (check out the yahoo group anodizing 101 for details - you can get some really pretty colors this way) and seal it. You can also coat it with a thin layer of a clear acrylic. Of course, if you really want ROCK hard, you can oxidize it, combine it with oxygen to make Al2O3 which is corundum, more commonly known as ruby/sapphire - one of the hardest materials known to man. You could also look up someone on the web that makes synthetic rubies and ask them to make you a ring from the ruby itself...then maybe do some engraving and gold leaf on it so that the metal is set in the gem rather than vice versa! That would be pretty cool! Also about as hard as you can get and totally unique.

- Q: How are aluminum coils manufactured to specific dimensions?

- Aluminum coils are manufactured to specific dimensions through a process known as rolling. In this process, large aluminum ingots are heated and then passed through a series of rolling mills, where they are gradually reduced in thickness and elongated. By adjusting the speed and pressure of the rolling mills, manufacturers can control the dimensions of the aluminum coils, ensuring they meet the required specifications.

Send your message to us

Green Aluminum Coil - Coated and Stucco Embossed Aluminium Coils Alloy 3003

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords