Cheap RP HD HP UHP Grade Graphite Electrodes for Electric Arc Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

Topfly Material has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line.

Graphite electrodes, widely used in steelmaking, non ferrous, silicon industry. According to their level of quality, it can be divided into RP, HP and UHP grade. The item here is HD grade graphite electrodes, Bulk Density: ≥1.58g/cm3, Resistivity: ≤8.5ohm. Diameter is 75-600mm, length is 1800±100mm. We welcome your inquiry!

2.Main Features of the Graphite Electrode

(1) Pure carbon content

(2) Competitive price

(3) High density ≥1.58g/cm3 and low resistivity ≤8.5ohm

(4) Large quantity in stock, about 2500MT.

(5) RP HP UHP grade for your choice

3.Graphite Electrode Images

More products for your reference:

Packaging: Wooden Pallets with Steel Strips

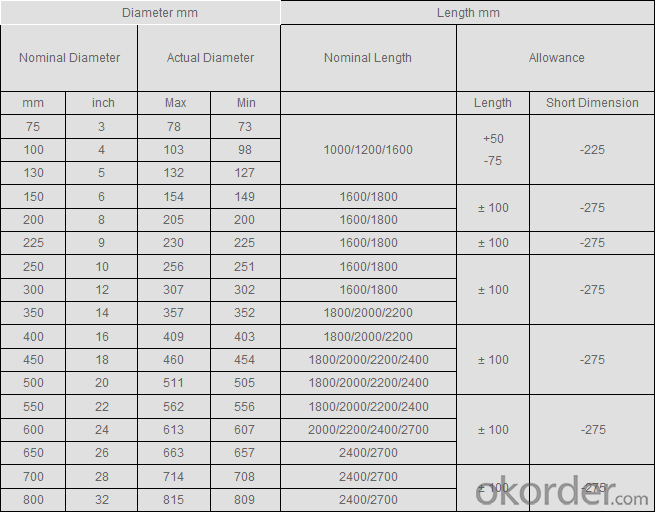

4.Graphite Electrode Specification

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(2) MOQ

For trial order, we accept 5 MT.

(3) Payment term

30% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q: What are the factors affecting the service life of graphite electrode in ultra high power arc furnace?

- China's graphite electrode quality standard (YB/T4090-2000) to evaluate the quality of the ultra high power graphite electrode is defined 6 physicochemical indexes, including resistivity, flexural strength, elastic modulus, bulk density and linear expansion coefficient as the quality evaluation index, ash as a reference index.

- Q: Why should supercapacitors use graphite as electrode material?

- Because the graphite material's electrochemical stability is good, can let the super capacitor withstand the higher monomer voltage. The electrode is not easy to wear out.

- Q: Use of graphite in steelmaking

- At present in the world (MgO-C brick raw material for graphite and magnesium) as refractory material, has been widely used in steelmaking, has become a traditional use of graphite.

- Q: What is the graphite furnace electrode with a diameter of 400?

- With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- The key is you use and what type of need, say, abroad, what Dongyang, sigley are good, but also, very expensive, you can also choose to try our home

- Q: What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- Carbon electrodes, however, are less likely to be less controllable because of their microstructure, or have some effect on the electric field, if they are sensitive signals

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- External electronic wire and the directional movement of ions in the solution of the directional movement between the poles of a closed loop, so that the two electrode reaction, electron transfer process, ordered a current converting chemical energy to electrical energy.Attention, here, "the ion does not go ashore, the electron does not enter the water"." That is the external circuit of graphite electrode is composed of electron flow and electrolyte ion flow; graphite electrode is to produce voltage and electrolyte, and to provide or absorb electrons

- Q: What's the use of carbon?

- Oxidation resistant coating graphite electrode. A graphite electrode coated with an antioxidant protective layer is applied to form a protective layer that is conductive and resistant to oxidation at high temperature, thereby reducing electrode consumption during steelmaking.

- Q: How long is the graphite electrode machining cycle?

- The dust produced in the processing of graphite electrode is relatively large, the possible intrusion to the machine tool guide screw and spindle, which requires a corresponding machining device of graphite graphite dust machine, sealing better, because the graphite toxic.

- Q: What is the application of wire cutting with graphite electrode?

- Machine: wire cutting wire, wire EDM, wire EDM wire is the cutting machine.

Send your message to us

Cheap RP HD HP UHP Grade Graphite Electrodes for Electric Arc Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches