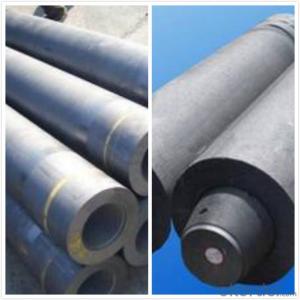

Graphite Electrode for Arc Furnace RP Grade

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 MT m.t.

- Supply Capability:

- 2000 MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Description

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to

700mm. Our products own the following characteristics: low electric resistance, good electric and

thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

Applications

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

Programmable properties

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

Graphite Electrode Grades

General Specifications for Graphite Electrodes

ITEM | Unit | UHP | HP | RP | |||

350-450mm | 500-700mm | 350-450mm | 500-700mm | 350-450mm | 500-700mm | ||

Bulk Density | g/cm³ | 1.65-1.73 | 1.65-1.74 | 1.62-1.72 | 1.62-1.72 | 1.54-1.61 | 1.54-1.61 |

Specific Resistivity | μΩM | 4.2-6.0 | 4.5-5.8 | 5.5-6.8 | 5.6-7.0 | 7.0-9.0 | 7.0-9.5 |

Flexural Strength | Mpa | 11.0-15.0 | 10.0-14.0 | 10.5-14.5 | 10.0-13.5 | 8.0-11.0 | 7.0-10.0 |

Elastic Modulus | Gpa | 8.5-11.0 | 8.0-12.0 | 6.0-9.3 | |||

CTE (100-600)°C | 10-6/C | 1.30-1.45 | 1.65-1.95 | 1.85-2.25 | |||

ASH | % | 0.1-0.3 | 0.1-0.3 | 0.1-0.3 | |||

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- During electrolysis, cations move toward the cathode, electrons are reduced at the cathode, anions are moved toward the anode, electrons are lost at the anode and oxidized. And you use both sides of the graphite rod, is inert electrode, so there will be no copper ions added to the solution, copper in the solution of consumption, the color of natural shallow.

- Q: What is the graphite furnace electrode with a diameter of 400?

- With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: Synthesis techniques of carbon nanotubes

- The synthesis techniques of carbon nanotubes are mainly arc method, laser ablation (Zheng Fa) method, catalytic cracking or catalytic chemical vapor deposition (CCVD), and directional control growth method based on various synthesis techniques.

- Q: What are the losses in graphite electrode?

- In what environment is the loss, friction, or in the case of high temperature, high temperature will be oxidized, and if in the case of friction, you can first use more wear-resistant graphite material. So please ask this question clearly, and then answer you, thank you.

- Q: How can the graphite powder be processed into high quality carburizing agent? Thank you

- So that impurities on the high, so basically can not be processed into so-called quality, and can leave a contact, discuss each other

- Q: What kinds of carbon are there?

- Graphite electrode class can be divided into ordinary power graphite electrode according to the allowable current density. High power electrode and ultra high power electrode.

- Q: What is anodized graphite?

- According to the production method of brush, there are two kinds. One is colored brush, that is, metal graphite brush. One is black brush. The black brush is made of petroleum coke, pitch coke, carbon black, charcoal and natural graphite powder and so on. Some binders (such as coal tar pitch, coal tar and artificial resin etc.) are added to the black brush. The resin binder by curing brush manufactured for high resistance brush, and the calcined product called carbon brush and graphite brush (with natural graphite as the main raw material) graphitised after product called electrographite brush,

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- The problem is this. I have done the test of electrolytic copper sulfate, and the anode produced the same phenomenon. Finally, the chemistry teacher told me that it was because the graphite was broken in the process of electrolysis

- Q: What about graphite electrodes for steel mills?

- Hebei North graphite electrode factory produces various specifications of graphite electrode, with low resistance, high density, small ash, and so on, so that less tons of steel-making, quality is good

- Q: Graphitized anode, cathode and graphite electrode, respectively How can one differentiate and use differently?

- Compared with other materials of graphite anode plate has high temperature resistance, good electrical and thermal conductivity, easy machining, good chemical stability, acid and alkali resistance, low ash content; for electrolytic solution, preparation of chlorine, caustic soda, salt alkali electrolytic solution preparation; application such as graphite anode plate can be used as conductive anode electrolytic salt solution preparation of caustic soda. Graphite anode plate can be used as conductive anode in electroplating industry. It is an ideal material for electroplating. It can make electroplating products have the advantages of smoothness, delicacy, wear resistance, corrosion resistance, high brightness and not easy to change color.

1. Manufacturer Overview

| Location | Shizuishan,China |

| Year Established | 2004 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | " Mid East;Western Europe;North America" |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Graphite Electrode for Arc Furnace RP Grade

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 MT m.t.

- Supply Capability:

- 2000 MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords