High Quality Graphite Electrode Chemistry for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications

Graphite Electrodes Used for steel making in arc furnace

Dia:200mm-500mm

Super quality

Competitive price

2. Specifications for RP, HP, UHP graphite electrodes with nipples:

RP | HP | UHP |

Electrode: Bulk Density≥ 1.56g/cm3 Elastic Modulus≤ 9.3GPa Thermal Expansion Coefficient≤ 2.7x10 -6/°C Ash≤ 0.5%

Nipple: Bending Strength≥ 14.0MPa Elastic Modulus≤ 13.7GPa Thermal Expansion Coefficient≤ 2.5 x10 -6/°C Ash≤ 0.5% | Electrode: Bulk Density≥ 1.65g/cm3 Elastic Modulus≤ 10.0GPa Thermal Expansion Coefficient≤ 2.2x10 -6/°C Ash≤ 0.3%

Nipple: Bending Strength≥ 16.0MPa Elastic Modulus≤ 14.0GPa Thermal Expansion Coefficient≤ 2.0 x10 -6/°C Ash≤ 0.3% | Electrode: Bulk Density≥ 1.68g/cm3 Elastic Modulus≤ 14.0GPa Thermal Expansion Coefficient≤ 1.9x10 -6/°C Ash≤ 0.2%

Nipple: Bending Strength≥ 18.0MPa Elastic Modulus≤ 16.0GPa Thermal Expansion Coefficient≤ 1.4 x10 -6/°C Ash≤ 0.2% |

3. Packing:

In wooden cases strapped with steel bands.

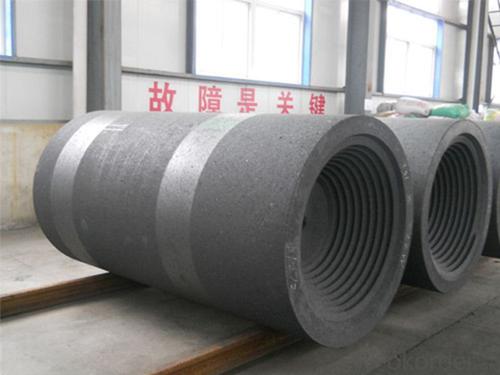

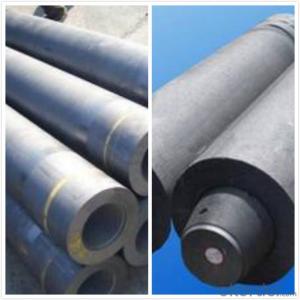

4.Pictures of Graphite Electrodes Factory

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty Graphite Electrodes with high power ?

Our factory could produce qualified products and good delivery time, cause we have many graphite electrodes in stock to our clients. So we can offer you stock products if you need urgent.

②How to guarantee the quality of the products Graphite Electrodes with high power?

We have established purchasing quality control system, and we have inspector in the factory to check the quality. each good should be appreoved by the inspectors ,then, could be permit to do shipment.;

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory to do production or do delivery as cusotmers' request.

- Q: Is graphite electrode good for foreign trade?

- I do graphite electrode production, but also do trade. The profit depends on the price you talked about. It should be around 2000.

- Q: What is the graphite furnace electrode with a diameter of 400?

- With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- Graphite electrode has good electrical and chemical stability. It has high mechanical strength, low impurity content and good vibration resistance at high temperature. It is a good conductor of heat and electricity. Qingdao Chenyang graphite graphite electrode quality is good, they are a direct manufacturer of graphite electrode. Hope to be of some help to you.

- Q: The use of graphite as an electrode in alumina electrolysis

- The technical knowledge of electrolytic aluminum, cleaning and maintenance of alumina equipment, you can search for Baidu on the green, looking for.

- Q: The reason why graphite is used as electrode

- Good chemical stabilityGraphite has good chemical stability at room temperature. It can resist acid, alkali and organic solvent.

- Q: The difference between graphite electrode and graphite rod

- The difference between an electrode and a rod is that the electrode has a lead conductor, and the rod is not.

- Q: What is the application of wire cutting with graphite electrode?

- Greatly shorten the preparatory time of mechanical processing, and improve the level of automation of the whole process of machining, and also enhance the ability of the manufacturing system to adapt to changes in production conditions.

- Q: Are graphite and carbon electrodes the same? What kinds of ore furnaces are used?

- Graphite electrode should be relatively pure, composed of graphite.

- Q: How does graphite produce solar cells?

- Gerrit J said: "despite the modifications, but the inherent nature of graphene remains unchanged, is a significant advantage of composite materials."

- Q: 800KVA and 12500 EAF transformer data graphite electrode furnace.

- Graphite project: Project Description: steel furnace and iron smelting furnace, ferrosilicon smelting, electrolytic aluminum and so on, all use large surface graphite electrode.

Send your message to us

High Quality Graphite Electrode Chemistry for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords