10 Oz Non Woven Geotextile Fabric for Dam Construction by Good Woven Geotextile Fabrics Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

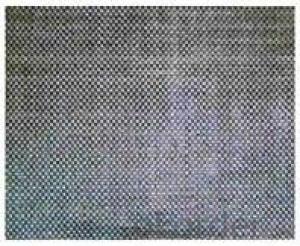

WOVEN GEOTEXTILES

1 High Performance

2 High Tensile Modulus

3 Monofilament

4 lit Film

Woven geotextiles consist of monofilament, multifilament, slit-film and/or fibrillated slit-film yarns - often in Woven geotextiles Image combinations - that are woven into a geotextile on conventional textile weaving machinery using a wide variety of traditional, as well as proprietary, weaving patterns. The variations are many and most have a direct influence on the physical, mechanical and hydraulic properties of the fabric.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

- Q: What are the considerations for geotextile selection in road rehabilitation projects?

- When selecting geotextiles for road rehabilitation projects, there are several important considerations to keep in mind. Firstly, the geotextile should have sufficient strength and durability to withstand the expected loads and stresses in the road environment. It should also be resistant to degradation from environmental factors such as ultraviolet (UV) radiation and chemicals. Another consideration is the desired function of the geotextile. Different types of geotextiles offer various benefits, such as separation, filtration, drainage, or reinforcement. The specific requirements of the road project will determine which function is most important. Additionally, the properties of the soil and subgrade should be considered when selecting a geotextile. The geotextile should be compatible with the soil type and provide the necessary soil stabilization or separation capabilities. It is crucial to assess the project's soil conditions and consult with geotechnical engineers or experts to determine the appropriate geotextile specifications. Lastly, cost-effectiveness is an essential consideration. The selected geotextile should provide the desired performance while being economically viable for the project. Considering the long-term benefits and expected lifespan of the geotextile can help in making a cost-effective decision. Overall, the considerations for geotextile selection in road rehabilitation projects involve strength, durability, desired function, compatibility with soil conditions, and cost-effectiveness.

- Q: Do you have a drainage board and geotextile on the roof

- Good, but you use very little, the purchase is difficult, the price will not be cheap Huazhi geotextile material manufacturers

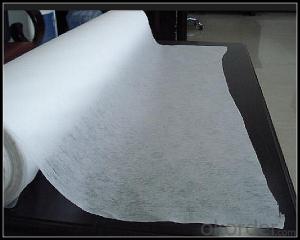

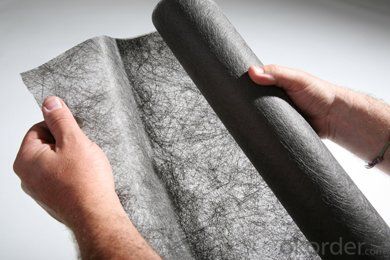

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: This is a large sample of gravel anti-filter how this project count

- Lack of slope and total length, can not accurately calculate the amount of engineering. Approximate estimates of cross-sectional area, then only a few simple graphics: clay tamping (rectangular), coarse gravel (trapezium), gravel and gravel (zoned plus parallel quadrilateral), geotextile (four sections)!

- Q: Geotextile cloth how many square feet

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: What are the different factors to consider for geotextile selection in mining applications?

- When selecting geotextiles for mining applications, several factors need to be considered. These include the required strength and durability of the geotextile to withstand the specific mining conditions, such as heavy machinery, abrasion, and chemical exposure. The permeability and filtration capabilities of the geotextile are also crucial to ensure proper drainage and prevent clogging. Additionally, factors like installation ease, cost-effectiveness, and compliance with environmental regulations should be taken into account to make an informed decision for geotextile selection in mining applications.

- Q: Can geotextiles be used in golf course construction?

- Yes, geotextiles can be used in golf course construction. They are often used to provide erosion control, soil stabilization, and drainage solutions in areas such as golf course bunkers, greens, fairways, and tee boxes. Geotextiles can help prevent soil erosion, improve water drainage, and enhance the overall durability and maintenance of golf course surfaces.

- Q: Consult geotextile and geomembrane is not the same thing?

- Geomembrane completely soiled geotextile is to keep the wet state of water will evaporate

- Q: PET geotextile is what?

- PET for the polyester on behalf of the name, PET geotextile is also divided into many kinds, such as: broken geotextile, filament geotextile, filament weaving, etc., I understand only these. Look at what you mean.

- Q: What is the role of geotextiles in geotechnical engineering?

- Geotextiles play a crucial role in geotechnical engineering as they are used to enhance soil stability, reinforce slopes, and improve drainage systems. These permeable fabrics help prevent soil erosion, control sediment movement, and distribute loads efficiently. Additionally, geotextiles can be employed in various construction projects, such as roadways, embankments, and retaining walls, to provide strength and durability to the soil structure.

Send your message to us

10 Oz Non Woven Geotextile Fabric for Dam Construction by Good Woven Geotextile Fabrics Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords