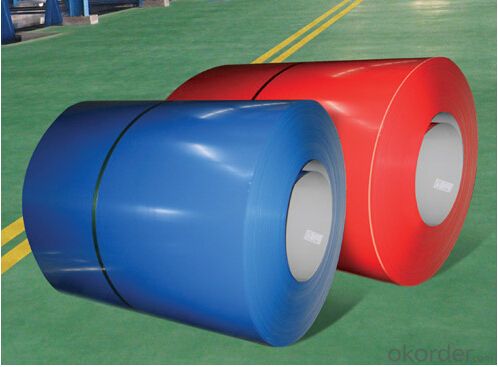

Good Quality of Prepainted Galvanized Steel Coil from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

2. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

3.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

- Q: How are steel coils used in the manufacturing of agricultural structures?

- Due to their durability, strength, and versatility, steel coils play a vital role in the manufacturing of agricultural structures. Typically made from high-quality steel, these coils are utilized in various ways throughout the construction process of agricultural buildings such as barns, silos, and storage facilities. One primary application of steel coils in agricultural structures is seen in the creation of the building's framework. The coils are unwound, cut into specific lengths, and then bent, shaped, and welded together to form the structural framework. The exceptional strength and rigidity of steel coils make them an ideal choice for withstanding the heavy loads and harsh environmental conditions commonly found in agricultural settings. Moreover, steel coils are also used in the production of different components and accessories for agricultural structures. These coils can be transformed into panels, roofing sheets, doors, and windows, which are essential elements in constructing agricultural buildings. The ability to customize the shape, size, and thickness of the steel coils allows for flexibility in design and ensures that the finished structure meets the specific requirements of the agricultural application. Furthermore, steel coils play a crucial role in providing protection and safety within agricultural structures. They are employed in fabricating fencing and gates, creating secure boundaries and preventing unauthorized access. Steel coils can also reinforce the walls and floors of the building, enhancing its stability and durability. Additionally, steel coils offer excellent resistance to corrosion, which is particularly important in agricultural structures due to exposure to moisture, chemicals, and other corrosive elements. Their durability ensures that the structure remains intact and functional for an extended period, thereby reducing maintenance and replacement costs. In conclusion, steel coils are indispensable in the manufacturing of agricultural structures. Their strength, durability, versatility, and resistance to corrosion make them an ideal choice for constructing the framework, components, and accessories of these buildings. By utilizing steel coils in the manufacturing process, agricultural structures can be built to withstand heavy loads, harsh environmental conditions, and provide long-lasting protection for agricultural operations.

- Q: What are the dimensions of steel coils used in the storage tank industry?

- The dimensions of steel coils used in the storage tank industry can vary depending on the specific requirements of the tank being manufactured. However, in general, steel coils used for storage tanks are typically available in various sizes and thicknesses. The width of steel coils can range from around 600 millimeters to 2,400 millimeters, while the length can vary from several meters to tens of meters. The thickness of the coils can also vary, typically ranging from 1.5 millimeters to 10 millimeters or more. These dimensions are determined by factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank. The specific dimensions for a given storage tank project would be determined by the tank manufacturer or designer, in accordance with industry standards and specific project specifications.

- Q: basically all the info you can find about s1 tool steel i found a bunch about annealing, and hardening, tinsel strength and stuff like that but i need MORE!!!!!

- S1 Tool Steel

- Q: Can steel coils be welded?

- Yes, steel coils can be welded. Welding is a common method used to join steel coils together or to other steel components, allowing for the formation of strong and durable connections in various applications.

- Q: can anyone tell me the way to bring back the shine to the stainless steel kitchen sink . It has become dull.

- after cleaning the sink, wipe down with a small amount of baby oil. it will shine like new.

- Q: What are the different types of steel coil coating materials?

- There exist various steel coil coating materials utilized in diverse industries and applications. Some frequently encountered types encompass: 1. Polyester: Renowned for their resilience and ability to withstand weathering, polyester coil coating materials find frequent application in outdoor settings like roofing and cladding. They offer exceptional protection against fading, chalking, and corrosion. 2. Polyvinylidene Fluoride (PVDF): PVDF coil coating materials exhibit remarkable resistance to chemicals, UV radiation, and weathering. They are commonly employed in architectural contexts, providing prolonged color retention and excellent defense against harsh environmental conditions. 3. Polyurethane: Possessing a high degree of flexibility and adhesion, polyurethane coil coating materials prove ideal for scenarios necessitating resistance to abrasion, impact, and bending. The automotive and appliance industries commonly rely on them. 4. Epoxy: Epoxy coil coating materials are celebrated for their remarkable adhesion and corrosion resistance. Industries such as metal furniture, storage tanks, and machinery frequently utilize them to ensure long-lasting protection against chemicals and abrasion. 5. Silicone Modified Polyester (SMP): SMP coil coating materials combine the robustness of polyester with the flexibility of silicone. They are prevalent in agricultural and industrial settings, offering outstanding resistance to chipping, cracking, and peeling. These merely serve as a few instances of the diverse array of steel coil coating materials currently available in the market. The selection of a coating material hinges upon the specific requirements of an application, including durability, weather resistance, chemical resistance, and aesthetics.

- Q: How are steel coils used in the manufacturing of automotive fenders?

- Steel coils are used in the manufacturing of automotive fenders by being processed and shaped into the desired fender shape. The coils are first uncoiled and then sent through a series of machines that cut and shape the steel into the specific dimensions and contours required for the fender design. These shaped steel pieces are then welded or bolted together to form the final fender structure, which is later painted and installed onto the vehicle.

- Q: I am thinking of buying a stainless steel necklace, but I need to know if it will discolor. My brothers ring turned brown, but he forgot what kind of metal it was. Also answer if I can wear it in the shower because I wear my other necklace in it.

- I would say don't wear it in the shower because it will tarnish and it could rust.

- Q: What are the dimensions of steel coils used in automotive part manufacturing?

- The dimensions of steel coils used in automotive part manufacturing can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry range from 0.5mm to 3mm in thickness and 600mm to 2000mm in width. The length of the coils can also vary, typically ranging from 1000mm to 6000mm.

- Q: What are the common processing defects in steel coils?

- The common processing defects in steel coils include surface imperfections such as scratches, dents, and stains, as well as edge wave, coil set, camber, and crossbow. Other defects may include coil breaks, oil spots, rust, and uneven thickness or width variation.

Send your message to us

Good Quality of Prepainted Galvanized Steel Coil from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords