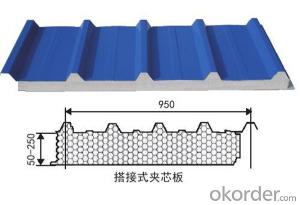

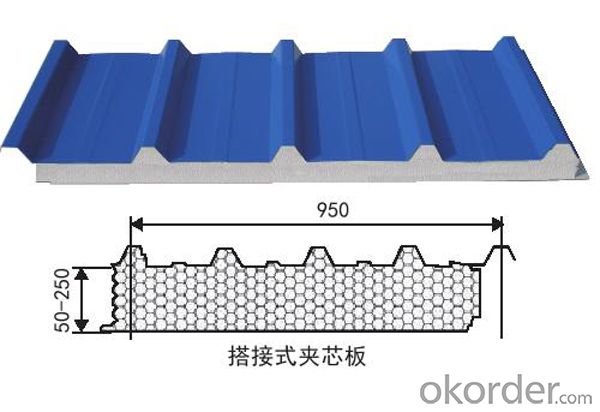

GL prepainted steel roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS | Grade: | AISI,ASTM,BS,DIN,GB,JIS | Thickness: | 0.17mm-0.6mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | Corrugated sheet | |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Roofing,Ceiling,Roof | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | as per customers request | Zinc coating: | 60-275g/m2 | Surface processing: | Regular spangle,minimal spangle |

Packaging & Delivery

| Packaging Detail: | Standard seaworthy or as your requirement. |

| Delivery Detail: | Within 9 days after confirming the order. |

Specifications

Prepaint corrugated roofing sheet

1.our material are from big mill

2.surface and edge is glossy

3.our package is export pa

Prepainted corrugated steel roofing sheets

Production

Standard | JIS G3302 1998, ASTM A653M/A924M 2004,or according to your request |

Thickness | 0.13mm-1.5mm |

Width | 400mm-1250mm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Length | We can adjust the length according to your request |

Wave depth | As to requirement |

Zinc Coating | 40g/m2-275g/m2 |

Surface treatment | Color-Coated & Galvanized |

Color | All RAL color |

Coat | 25±5μm on front coating and 7± 2μm on back coating |

Temper | 1.Full hard |

2.Commercial quality | |

3. Dry, chromate, skin passed, tension level, shining. | |

Spangle | Regular spangle, minimized spangle and zero spangle |

Tensile Strength | >300mpa |

Yield Strength | 370-380mpa |

Application | various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

MOQ | 50Ton |

Specification

Process ability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

- Q: Can steel sheets be used for construction formwork or molds?

- Yes, steel sheets can be used for construction formwork or molds, although they may not be as commonly used as other materials such as plywood or timber. Steel sheets are durable, strong, and can provide a smooth and even surface for casting concrete. They are particularly suitable for large-scale construction projects where formwork needs to withstand high pressures and loads. Steel sheets can be custom-designed and fabricated to meet specific project requirements, offering flexibility in shape, size, and configuration. However, it is important to consider the cost, weight, and availability of steel sheets compared to other formwork materials before making a decision.

- Q: What is the average thickness of steel sheets?

- The average thickness of steel sheets can vary depending on various factors such as the specific type of steel, its intended application, and industry standards. However, in general, steel sheets can range in thickness from around 0.4 millimeters (0.016 inches) to several millimeters (0.1 inches or more). It is important to note that different industries and applications may have specific requirements for steel sheet thickness, so it is always best to consult relevant standards or specifications for accurate information.

- Q: Do the steel sheets have a smooth surface finish?

- Indeed, the steel sheets possess a polished surface texture.

- Q: Can steel sheets be used for manufacturing electrical enclosures?

- Yes, steel sheets can be used for manufacturing electrical enclosures. Steel is a commonly used material for constructing electrical enclosures due to its durability, strength, and ability to provide necessary protection for electrical components. The use of steel sheets ensures that the enclosure is sturdy and can withstand various environmental conditions. Additionally, steel offers good electromagnetic shielding properties, which can help protect sensitive electronic equipment from interference. Steel sheets are also fire-resistant, making them suitable for manufacturing enclosures that need to meet safety regulations. Overall, steel sheets are a reliable choice for manufacturing electrical enclosures due to their characteristics and suitability for the purpose.

- Q: What is the difference between a brushed and polished steel sheet?

- A brushed steel sheet and a polished steel sheet differ in terms of their surface finishes. A brushed steel sheet is characterized by a pattern of parallel lines or scratches on its surface, created using abrasive materials or tools. The purpose of brushing is to give the steel sheet a textured appearance, which helps to hide fingerprints, scratches, and wear over time. It also provides a more industrial, matte finish. On the other hand, a polished steel sheet has a smooth and glossy surface. Polishing involves using polishing compounds or abrasive materials to remove imperfections, scratches, and oxidation from the steel surface. This process creates a reflective and mirror-like finish, enhancing the aesthetic appeal of the steel sheet. Polished steel sheets are commonly used in applications where appearance and visual appeal are important, such as architectural design, interior decoration, and high-end products. In summary, the main difference between a brushed and polished steel sheet lies in their surface finishes. Brushed steel sheets have a textured, matte appearance, while polished steel sheets have a smooth and glossy, mirror-like finish. The choice between the two depends on the desired aesthetic, functional requirements, and the intended application of the steel sheet.

- Q: What are the common thicknesses available for steel sheets?

- The common thicknesses available for steel sheets typically range from 0.5 mm to 25 mm, depending on the specific application and industry requirements.

- Q: What are the different thickness gauges available for steel sheets?

- There are several thickness gauges available for steel sheets, including the commonly used gauges such as 18, 20, 22, 24, and 26 gauge.

- Q: Can steel sheets be used for food processing or storage?

- No, steel sheets should not be used for food processing or storage. While steel is a durable and commonly used material in many industries, including food processing, it is not suitable for direct contact with food. Steel sheets may contain various chemicals, such as zinc coating or other metallic coatings, which can potentially contaminate the food and pose health risks. Additionally, steel sheets are prone to rusting, and the presence of rust can also contaminate the food. Therefore, it is recommended to use food-grade materials such as stainless steel or food-grade plastic for food processing and storage to ensure the safety and quality of the food.

- Q: What are the different sheet metal joining techniques for steel sheets?

- Steel sheets can be joined using various techniques. Welding is commonly used, where the edges of the sheets are melted and fused together using heat and pressure. Different welding techniques like arc, spot, or laser welding can be used depending on the requirements. Riveting is another method, involving the use of metal fasteners called rivets. Holes are drilled in the sheets, and the rivets are inserted and deformed to secure the joint. This technique is suitable for structural applications due to its strength and durability. Bolting involves using bolts and nuts to connect the sheets. Holes are drilled, and bolts are inserted through them, with nuts tightened on the other side. Bolting allows for easy disassembly and reassembly, making it suitable for applications requiring frequent maintenance or repairs. Adhesive bonding is a technique where a strong glue is used to bond the sheets. The adhesive is applied between the surfaces, and pressure is applied for proper bonding. This method provides a clean and aesthetically pleasing joint without the need for drilling holes or using fasteners. Clinching is a cost-effective and quick method for joining steel sheets. It involves deforming the sheets using a punch and die, creating a mechanical interlock. This technique does not require additional materials and is suitable for various applications. The choice of joining technique depends on factors such as the specific application, required strength, durability, cost, and ease of assembly. Each technique has its own advantages and limitations.

- Q: How much is one meter for laser cutting steel plates?

- The above price is for low carbon steel. The price of stainless steel is lower than that of low carbon steel. Mainly nitrogen, a large amount.Of course, the specific price with the processing capacity of the size, the shape of the parts (compare all holes can not be completely by the meter, whether to count) freight, whether it is with material processing have a great relationship.

Send your message to us

GL prepainted steel roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords