Geotextile Menards PP Nonwoven Geotextile with High Strength for Road Construction and Civil Engineering Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

1. Specifications for PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

Material | PP(polypropylene) or PET(polyester) |

Technics/process | Needle punched / thermally bonded |

Specification | 100g/m-1300g/m2 |

Width | 1m6m(as you demand) |

Length | 100m(as you demand) |

Colour | White, black |

Packing | PE film and woven cloth |

Load | According to your specification |

Payment terms | T/T or L/C |

Delivery time | Within 3 weeks |

Application | Geotextiles with various indicators of quality, with good stress -- strain and toughness, seepage performance and uniformity, and width, etc., And is applicable to roads, water, rail, mining dams, rivers, airports and other civil engineering, anyone in the works played reinforcement, segregation, filtration, filtration, drainage, and then extend the project life, reduced cost and easy construction, and it is easy to ensure the quality of the project. |

2. Property for PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

1). Good air and water permeability-interspace in the fibers made it favorable water permeability.

2). Corrosion resistant-geotextile is made from polyester, featuring resistance to acid and alkali ,non-corroding,no worm-eaten,anti-oxidation.

3). Good water transmissibility and filtration- it can form drainage channels inside soil mass to drain redundant water and air out of the soil mass.

4). High intensity-geotextile can keep sufficient strength and elongation in dry and wet condition due to the use of plastic fiber.

5). Easy construction,low weight,easy operation,simple construction

3. Property for PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

1). Isolation

Short fiber needle punched geotextile can prevent the mixture of construction

materials featuring different physical properties (such as soil mass and sandstone,soil mass and concrete)

2). Filtration

Its good water and air permeability let water flow through it so as to effectively control

sandrock running down.

3). Reinforcement

Geotextile helps to enhance the soil mass tensile strength and non-deformability and structural stability so as to improve soil mass quality.

4). Protection

It can effectively make the concentrated stress diffuse,transfer or decompound,and guard the soil mass against the destruction of external force.

5). Anti-puncture

Combine with geomembrane and form compound waterproofing material to act a part of anti-puncture.

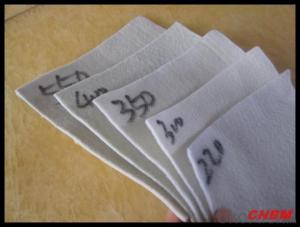

4. Photos for PP/PET Needle Punched Short Fiber Nonwoven Geotextile for Road Construction

- Q: 300g / m2 geotextile package is what it means

- 300g / m2 Geotextile: refers to the weight of 300g per square meter (model) 300g / m2 geotextile package: refers to the outsourcing; with 300g of geotextile to wrap something; for example: With 300g / m2 geotextile wrapped gravel. The

- Q: How do geotextiles help in the reinforcement of soil?

- Geotextiles help in the reinforcement of soil by providing stability and strength to the soil structure. They act as a barrier between different soil layers, preventing their mixing and maintaining their integrity. Geotextiles also distribute the load evenly across the soil, reducing the risk of settlement or subsidence. Additionally, they improve drainage and filtration by allowing water to pass through while preventing the loss of fine particles. Overall, geotextiles enhance the overall performance and longevity of soil in various engineering and construction applications.

- Q: Geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: Can geotextiles be used in embankment reinforcement?

- Yes, geotextiles can be used in embankment reinforcement. Geotextiles are commonly used in civil engineering projects to improve the stability, strength, and durability of soil structures such as embankments. They are placed within the soil layers to provide reinforcement, filtration, and drainage capabilities, reducing the risk of erosion and enhancing the overall performance of the embankment.

- Q: How are geotextiles tested for quality assurance?

- Geotextiles are tested for quality assurance through a series of standardized tests and evaluations. These include physical properties testing such as tensile strength, tear resistance, and puncture strength, as well as hydraulic properties testing like permeability and filtration efficiency. Additionally, durability and chemical resistance tests are conducted to ensure the geotextiles can withstand long-term exposure to various environmental conditions. These rigorous quality assurance measures help to determine the performance and suitability of geotextiles for specific applications.

- Q: Geotextile and geogrid difference

- Different geotextile used to prevent seepage, geogrid used to reinforce the geotextile is mainly used to seepage, isolation, geogrid are generally used in reinforced reinforcement, the two are essential differences in the use of the process Sometimes used in the same project, such as high-speed, railway and other engineering production grid is made of polypropylene, polyvinyl chloride and other polymer polymer by thermoplastic or molded two-dimensional grid or a certain height of the three-dimensional Dimensional grid grid, when used as a civil engineering, known as geogrid. Engineering applications: roads, railways, abutments, approach roads, docks, dams, slag and other soft soil foundation reinforcement, retaining walls and road surface cracking engineering and other fields. Fiberglass mesh used in the external walls, wall paint, the main material to prevent the junction of different mortar and other plastering material cracking, hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Common non-woven fabrics, water layer inside the use, polyethylene polypropylene waterproof also used.

- Q: Where can the general use of geotextile water can be bought

- Huashi geotextile manufacturers need to be linked

- Q: Are geotextiles commonly used in riverbank protection applications?

- Yes, geotextiles are commonly used in riverbank protection applications. They are used to stabilize the soil, prevent erosion, and provide a barrier against high water flow. Geotextiles are often preferred due to their durability, permeability, and ability to withstand harsh environmental conditions.

- Q: Filtering geotextile calculation

- The amount of consultation and happy it

- Q: How do geotextiles help with filtration in drainage systems?

- Geotextiles help with filtration in drainage systems by acting as a barrier that prevents the passage of fine particles while allowing water to pass through. They effectively filter out sediment, debris, and other contaminants, ensuring that only clean water flows through the drainage system. This helps to maintain the system's functionality and prevent clogging or blockages.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geotextile Menards PP Nonwoven Geotextile with High Strength for Road Construction and Civil Engineering Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords