Geotextile Bricoman - Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

1. Introduction of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

Filament woven geotextile: It is made of high strength polypropylene, polyester, nylon or mixed them together, all of which keep the original strength.

They were wovened together to form the pilotaxitic texture, which can keep certain structure and improve the original strength, It is widely used in river, coast, harbour, highway, railway, wharf, tunnel, bridge and other geotechnical engineering.

The woven geotextile is a invaluable product and can be used for different kinds of request, for example, filtrition, seperation, reinforcement, protection and others.

2. Property of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

High strength: Low deformation

Durability: Steady property, not easy to resolved, air-slaked and can keep the original property long term,

Anti-erosion: Anti-acid, anti-alkali, resist insects and mould.

Permeability: The woven geotextile can control the sieve size to retain certain permeability.

3. Specifications of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

Specification: 100g/m2-800g/m2

Material: Polypropylene or Polyester

Width: 1-7m

Length: 50-100m or as request

Color: White

Certificate: ISO9001 ISO14001 BV

4. Technical Data of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

PP Polypropylene Pet Polyester Continuous Filament Woven Geotextile | |||||||||||

Physical Properties | Test method | Unit | Typical Value | ||||||||

Material | Polyester/Polypropylene | ||||||||||

Unit Weight | ASTM D 5261 | g/m2 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1300 |

Color | White | ||||||||||

Mechanical Properties | |||||||||||

Tensile strength at break MD | ASTM D 4595 | KN/M ≥ | 50 | 75 | 100 | 130 | 160 | 180 | 200 | 230 | 360 |

Tensile strength at break CD | ASTM D 4595 | KN/M ≥ | 35 | 52 | 70 | 90 | 112 | 126 | 140 | 160 | 280 |

Elongation at break MD | ASTM D 4595 | % ≤ | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

Elongation at break CD | ASTM D 4595 | % ≤ | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

CBR Puncture Strength | ASTM D 6241 | KN | 4 | 6.9 | 11 | 14 | 18 | 20.5 | 23 | 24 | 28 |

Tear Strength | ASTM D 4533 | KN | 0.6 | 1 | 1.3 | 1.6 | 1.9 | 2 | 2.2 | 2.3 | 3.2 |

Hydraulic Properties | |||||||||||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | ||||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | ||||||||

Width:max 5.4m standard 3.6m other colors available | |||||||||||

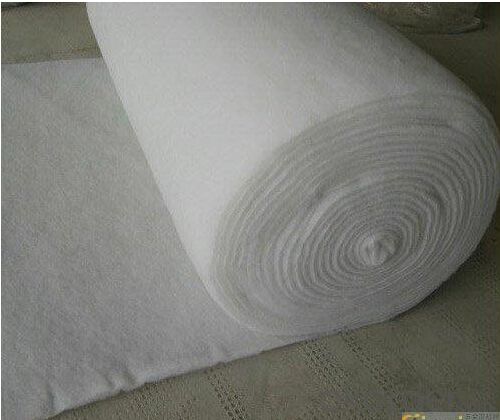

5. Some Photos of Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles for Construction Use

6. RFQ

1) What's your payment terms?

T/T or L/C at sight

2) What's your delivery time?

Within 15days against deposit received or original LC received

3) What's your pacakge?

Per roll with one woven bag

- Q: What are the different factors to consider for geotextile selection in agricultural applications?

- Some of the different factors to consider for geotextile selection in agricultural applications include the required strength and durability of the geotextile, permeability and filtration properties, resistance to chemicals and biological degradation, compatibility with soil and crops, installation and maintenance requirements, and cost-effectiveness.

- Q: Are geotextiles suitable for use in railway ballast stabilization?

- Yes, geotextiles are suitable for use in railway ballast stabilization. Geotextiles help to improve the strength and stability of the ballast layer by preventing the migration of fines and providing reinforcement. They also help to distribute loads evenly, reduce track settlement, and increase the overall lifespan of the railway track.

- Q: Can geotextiles be used for reinforcement of paved surfaces?

- Yes, geotextiles can be used for reinforcement of paved surfaces. Geotextiles are commonly used in civil engineering projects as a way to enhance the performance and longevity of paved surfaces. They provide reinforcement and stabilization by distributing loads and reducing the risk of cracking, rutting, and other forms of pavement distress. Additionally, geotextiles can also serve as a barrier against moisture and prevent the intrusion of fine particles into the pavement layers.

- Q: Can geotextiles be used in embankment reinforcement?

- Yes, geotextiles can be used in embankment reinforcement. Geotextiles are commonly used in civil engineering projects to improve the stability, strength, and durability of soil structures such as embankments. They are placed within the soil layers to provide reinforcement, filtration, and drainage capabilities, reducing the risk of erosion and enhancing the overall performance of the embankment.

- Q: How do geotextiles affect groundwater flow?

- Geotextiles can either enhance or restrict groundwater flow depending on their permeability and installation method. Permeable geotextiles can allow water to infiltrate through them, facilitating groundwater recharge and promoting natural drainage. Conversely, impermeable geotextiles can prevent water from passing through, altering the natural flow of groundwater and potentially causing waterlogging or surface runoff issues. The selection and proper installation of geotextiles are crucial to ensure they positively impact groundwater flow and maintain the hydrological balance of an area.

- Q: Geotextile seepage seams how to deal with

- First geotextile is not waterproof, you say is a composite geomembrane, seams with a welding machine welding, can also use ks hot melt welding. Huazhi engineering materials manufacturers to answer your questions

- Q: Are geotextiles resistant to chemicals?

- Yes, geotextiles are generally resistant to chemicals.

- Q: Can geotextiles be used in coastal erosion control structures?

- Yes, geotextiles can be used in coastal erosion control structures. Geotextiles are commonly used to stabilize slopes, reinforce soil, and control erosion in various construction projects. In coastal areas, they can be employed to prevent erosion of beaches, dunes, or shorelines by acting as a barrier against the movement of sediment and soil. Geotextiles provide an effective solution for coastal erosion control structures due to their permeability, strength, and ability to withstand harsh environmental conditions.

- Q: How do geotextiles help in preventing soil erosion in agricultural fields?

- Geotextiles help in preventing soil erosion in agricultural fields by acting as a barrier between the soil and external forces such as wind and water. They stabilize the soil by reducing surface runoff, preventing sedimentation, and promoting the growth of vegetation. Geotextiles also enhance filtration and drainage, allowing water to flow through while retaining soil particles, thus minimizing the risk of erosion.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geotextile Bricoman - Continuous Filament Spunbond Needle Punched Polypropylene or Polyester Geotextiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords