Geotextil Nt 2500 Thermal Non-Woven Geotextile for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

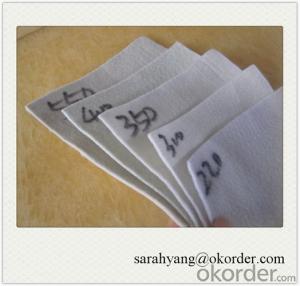

1. Specifications

1) Weight / Mass: 100g/m2-800g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PET

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: What are the key differences between woven and nonwoven geotextiles?

- The key differences between woven and nonwoven geotextiles lie in their manufacturing processes and physical characteristics. Woven geotextiles are made by interlacing yarns or fibers together to create a stable and strong fabric. On the other hand, nonwoven geotextiles are produced by bonding or felting fibers together without any weaving process. In terms of physical characteristics, woven geotextiles generally have higher tensile strength and puncture resistance due to their interlaced structure. They also offer better filtration properties as the open spaces between the woven yarns allow for effective water flow. Nonwoven geotextiles, however, have a higher permittivity, meaning they have a greater ability to allow water to pass through. Another notable difference is their durability. Woven geotextiles tend to be more resistant to UV degradation and offer better long-term performance, making them suitable for applications that require high strength and stability over time. Nonwoven geotextiles, although less durable, are often used for short-term projects or where filtration and separation are the main requirements. Overall, the choice between woven and nonwoven geotextiles depends on the specific application and desired properties. Woven geotextiles are typically favored for their strength and longevity, while nonwoven geotextiles are preferred for their filtration capabilities and cost-effectiveness in certain applications.

- Q: Are geotextiles resistant to rodent penetration?

- Yes, geotextiles are generally resistant to rodent penetration.

- Q: Construction Method of Sand and Gravel Cushion on Slope Soil Geotextile

- Online to find some relevant construction methods, Google library on a lot. After downloading, modify, targeted to add that is the slope of geotextile sand and gravel cushion construction method.

- Q: Geotextile longitudinal and lateral elongation gap is too much how to adjust

- 1. The elongation at break of the geotextile is divided into longitudinal elongation at break and transverse elongation at break. Generally speaking, the elongation at longitudinal and transverse faults is not very different. GB GB / T-2008 standard requirements geotextile longitudinal and lateral elongation between 20% -100% are qualified. 2. Longitudinal transverse fracture elongation gap is too large, you can check the mixing hopper, carding machine is mixed evenly, combing evenly. 3. Acupuncture machine too fast or too high acupuncture may lead to geotextile longitudinal and transverse elongation gap, you can try to debug the speed of the next needle machine. 4. Appropriate to add some industrial oil can enhance the geotextile rupture strength, and elongation at break.

- Q: Can geotextiles be used in agricultural applications?

- Yes, geotextiles can be used in agricultural applications. Geotextiles are commonly employed in agriculture for various purposes such as soil stabilization, erosion control, weed suppression, and drainage management. They can be used to enhance crop growth, reduce soil erosion, and improve water filtration, making them a valuable tool in agricultural practices.

- Q: How do geotextiles contribute to the safety of transportation infrastructure?

- Geotextiles play a crucial role in enhancing the safety of transportation infrastructure by providing soil stabilization, erosion control, and drainage management. They prevent soil movement and erosion, which can undermine the stability of roads, slopes, and embankments. Geotextiles also help improve the load-bearing capacity of the soil, reducing the risk of structural failure or settlement. Additionally, these materials promote effective drainage by allowing water to pass through while filtering out fine particles, preventing waterlogging and soil saturation. Overall, geotextiles contribute to the overall durability, longevity, and safe functioning of transportation infrastructure.

- Q: What is the representative batch of geotextile?

- Geotextile batch is 2000 square meters.

- Q: What are the different geotextile installation techniques in filtration?

- Some of the different geotextile installation techniques in filtration include direct placement, trench installation, and wrapping. Direct placement involves placing the geotextile directly on the soil surface, while trench installation involves burying the geotextile in a trench or cut. Wrapping technique involves wrapping the geotextile around a structure or pipe to provide filtration. These techniques are used to enhance filtration and prevent soil erosion in various construction and environmental projects.

- Q: Can geotextiles be used for reinforcement of pipeline trenches?

- Yes, geotextiles can be used for the reinforcement of pipeline trenches. They provide stability and support by preventing soil erosion and minimizing the movement of soil particles. Additionally, geotextiles can enhance the overall performance and longevity of the pipeline by reducing stress on the pipes and preventing damage caused by shifting soil.

- Q: How do geotextiles help in separating different soil layers?

- Geotextiles help in separating different soil layers by acting as a barrier between the layers, preventing their intermixing. The geotextiles have a permeable structure that allows water to pass through while retaining the soil particles, thus maintaining the integrity of each layer. This separation is crucial in various applications, such as road construction, landscaping, and erosion control, as it enhances the stability and performance of the soil layers.

Send your message to us

Geotextil Nt 2500 Thermal Non-Woven Geotextile for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords