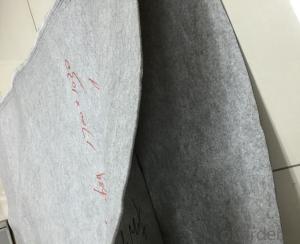

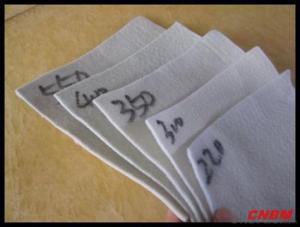

Geotextil 300 Gr/M2 Geogrid Geotextile Short Fiber Non Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

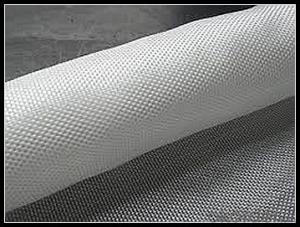

Uniaxial Geogrid

It is is a smooth high density proethylene(HDPE) Geogrid manufactured with the highest quality . This product is used in applications that require excellent chemical resisitance and endurance properties.

Properities of Uniaxial Geogrid :

High strength , Good flexibility, anti-aging, resisting acid and Alkaline.

Usage of Uniaxial Geogrid :

Make reinforcement for various kinds of soil foundation enhance and improve bearing ability if the roadbed .make reinforcement for retaining wall, steep slope, dam and bridge abutment under stress status for long term thus to improve quality and prolong service life of the project .

Specification of the Uniaxial Geogrid

TGDG35 TGDG50 TGDG80 TGDG110 TGDG120 Width : <= 2.5m

Length : 50—100m Color : black

Packaging : Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods: within 15 days after receiving the deposit

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in green roof applications?

- Yes, geotextiles can be used in green roof applications. Geotextiles are often used as a protective barrier or filter layer in green roofs to prevent soil erosion and aid in drainage. They can help retain moisture and provide stability to the growing medium, promoting healthy plant growth on green roofs.

- Q: Can geotextiles be used in the protection of bridge abutments?

- Yes, geotextiles can be used in the protection of bridge abutments. Geotextiles are commonly employed to provide erosion control, soil stabilization, and filtration in various civil engineering applications. By placing geotextiles along the abutments, they can help prevent soil erosion, reinforce the embankment, and provide a stable foundation for the bridge structure, thereby enhancing the overall protection of bridge abutments.

- Q: 300 grams per square meter of anti-geotextile there? what price

- Hello, 300 grams of geotextile with less, the best near the purchase of the specific price of the price can be a private letter or telephone I Hua Zhi geotextile material manufacturers for you to answer

- Q: What is the use of the black network when the shop is paved?

- Roadbed can not hold, tamper with, it is similar to the old man with a mud house, mud with a wheat bran

- Q: Roof geotextile isolation layer sets what the amount

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: What is the effect of highway geotextile on highway construction?

- Highway geotextile is a new type of civilized artifacts in the construction of the time, laying highway geotextile can improve the carrying capacity of the road, can improve the use of the road in the process of structural damage. As the geotextile has the role of shock absorption, and has a high elasticity and resistance to deformation, so you can make the road to bear the load and stress more uniform. In the project using Hongxiang new geotextile can also improve the rigidity of the road, help to reduce road cracks.

- Q: Can geotextiles be used in soil erosion control on construction sites?

- Yes, geotextiles can be used in soil erosion control on construction sites. Geotextiles are permeable fabrics that can be placed on the soil surface to prevent erosion by stabilizing the soil and allowing water to pass through while retaining sediment. They are effective in controlling erosion, reducing sediment runoff, and maintaining soil integrity during construction activities.

- Q: Are geotextiles environmentally friendly?

- Yes, geotextiles are environmentally friendly. They are made from natural or synthetic fibers that are biodegradable and do not release harmful substances into the environment. Geotextiles also help to prevent soil erosion, promote vegetation growth, and improve water quality, making them a sustainable solution for various environmental applications.

- Q: Composite geotextile 20-500-0.5 what it means

- You should not write it right

- Q: Geotextile price

- I am specializing in the production of geotextile and other materials, wish smooth

Send your message to us

Geotextil 300 Gr/M2 Geogrid Geotextile Short Fiber Non Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords