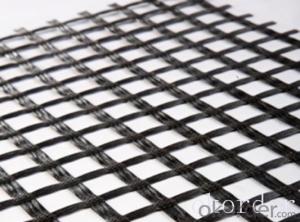

Uniaxial High Strength Geogrids with Highest Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Biaxial

In case of water streams construction, geogrid application allows planting trees and shrubs along the banks protecting them from ablation. Geogrids are an economical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

20KN/M--50KN/M

Material:

Plastic

width:

1-6m

Certificate:

CE,ISO

Production function

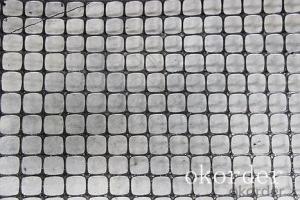

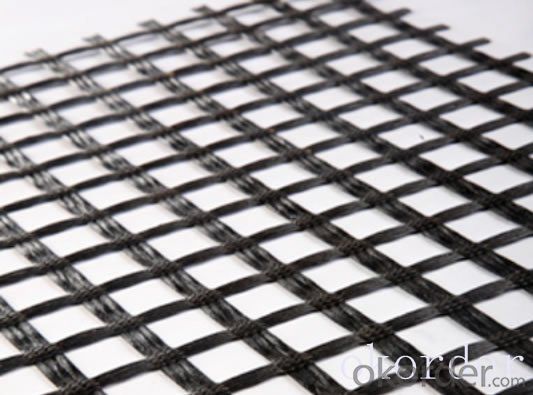

1:Tensile strength, high creep degeneration small, it has good flexibility, low elongation at break, and effectively solved the engineering distortion and quite a shift, adapt to the environment soil, and can meet the retaining wall of high grade highway tall role.

2:Effectively improve the bearing the reinforcement embedded locks, bite role, great enhancement the bearing capacity of the foundation, effective constraint of soil lateral displacement, enhance the foundation stable performance.

3: Compared with the traditional grille has more strength, high bearing capacity is strong, prevent ageing, friction coefficient.

4: Effectively avoid in construction process by a few words of rolling, damage caused by the construction damage.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the distance between the waterproof plate and the top of the tunnel? What are the relevant provisions of this specification?

- Some of the design drawings, the specification seems to be unable to find, which is related to the location of longitudinal flexible drainage pipe

- Q: How do geogrids improve the performance of retaining walls?

- Geogrids improve the performance of retaining walls by providing tensile strength and reinforcement to the soil, thereby increasing the stability and load-bearing capacity of the wall. They prevent soil erosion and lateral movement, reducing the risk of wall failure. Additionally, geogrids distribute the applied loads more uniformly, minimizing differential settlement and reducing the overall stress on the retaining wall structure.

- Q: What are the factors that affect the installation quality of geogrids?

- There are several factors that can affect the installation quality of geogrids. These include the preparation of the subgrade or foundation, proper alignment and positioning of the geogrid, adequate tensioning during installation, proper overlapping or connection of geogrid panels, and adequate cover material to protect the geogrid from damage. Additionally, factors such as soil type, compaction, and environmental conditions can also influence the overall installation quality of geogrids.

- Q: Can geogrids be used in retaining wall drainage systems?

- Yes, geogrids can be used in retaining wall drainage systems. Geogrids are commonly used to reinforce soil and provide stability to retaining walls. They can also be employed as part of a drainage system to help manage water pressure and prevent the accumulation of excess water behind the wall. By allowing for efficient drainage, geogrids can enhance the overall performance and longevity of retaining walls.

- Q: How do geogrids improve pavement performance?

- Geogrids improve pavement performance by enhancing the structural integrity of the pavement layers. They distribute the load and stress more evenly, reducing cracking and rutting. Geogrids also prevent the lateral movement of soils, which helps to maintain the stability of the pavement and reduces maintenance costs in the long run.

- Q: What are the advantages of using geogrids in ground improvement for settlement control?

- Geogrids offer several advantages in ground improvement for settlement control. Firstly, they provide increased soil stability by distributing loads more evenly, thereby reducing settlement and preventing soil erosion. Secondly, geogrids enhance soil reinforcement, increasing the bearing capacity of the ground and allowing for the construction of heavier structures. Additionally, these materials are easy to install and cost-effective, saving time and money during the ground improvement process. Overall, geogrids offer a reliable and efficient solution for settlement control and improved ground stability.

- Q: Are geogrids suitable for use in mining applications?

- Yes, geogrids are suitable for use in mining applications. Geogrids are commonly used in mining operations for various purposes such as soil stabilization, slope reinforcement, and erosion control. They provide strength and stability to the mining infrastructure, improving safety and efficiency. Additionally, geogrids are cost-effective and durable, making them an ideal choice for mining applications.

- Q: What is the typical geogrid roll weight for specific applications?

- The typical geogrid roll weight for specific applications can vary depending on the specific requirements and design considerations of the project. However, geogrid rolls used in common applications such as soil stabilization or retaining wall construction typically range from 20 to 100 pounds per roll.

- Q: What are the typical properties and characteristics of geogrids?

- Geogrids are typically made of high-strength polymers or fiberglass materials and are used in civil engineering applications such as soil stabilization and reinforcement. They possess a high tensile strength, allowing them to distribute loads more effectively and improve the overall stability of the soil. Geogrids also exhibit excellent resistance against biological degradation, chemicals, and UV rays, ensuring their durability and long lifespan. They have a flexible and lightweight nature, making them easy to handle and install. Geogrids are known for their ability to improve soil confinement, prevent soil erosion, and enhance the performance of various construction projects.

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials made from polymers, typically high-density polyethylene (HDPE) or polyester, that possess a unique set of properties and characteristics. These include high tensile strength, low elongation, and excellent resistance to chemical degradation and biological attack. Geogrids also have a high modulus of elasticity, which allows them to distribute stress and improve the load-bearing capacity of soils and aggregates. They are typically lightweight and easy to handle, making them convenient for construction applications. Geogrids exhibit excellent dimensional stability and resistance to creep, ensuring their long-term effectiveness. They are also resistant to UV degradation and have a long design life. Overall, geogrids are versatile materials that provide reinforcement, stabilization, and confinement in various civil engineering projects, such as road construction, slope stabilization, and erosion control.

Send your message to us

Uniaxial High Strength Geogrids with Highest Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords