Geogride Stragrip Sg-150 Self-Adhesive Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Self-Adhesive Fiberglass Geogrid Description:

Self-Adhesive Fiberglass Geogrid can be used to enhancement of permanent bearable toft including roads and railways embankment, slopes, tunnel, airfields, parks, docks and ground which cargo lays on and their main usage

Main Features of Self-Adhesive Fiberglass Geogrid:

1.Enhance the bearing capacity of road foundation and extend the duration of roads.

2.Prevent road surface from collapse, crack and being dirty.

3.Be convenient for construction, timesaving and cut down the cost of maintenance.

4.Prevent tunnel from crack occurring.

5.Further solidity slopes to proof water and soil from losses.

6.Reduce the surface thickness of the ground.

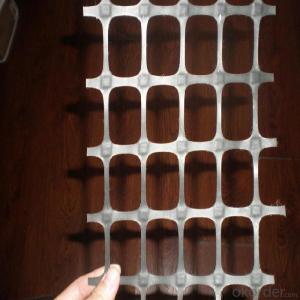

Self-Adhesive Fiberglass Geogrid Images

Self-Adhesive Fiberglass Geogrid Specification:

Item | TGSG15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | |||||

Unit | MD | CD | MD | CD | MD | CD | MD | CD | |

True initial Modulus in Use | KN/m | 15 | 15 | 20 | 20 | 30 | 30 | 40 | 40 |

True Tensile Strength @2% Strain | KN/m | 5 | 5 | 7 | 7 | 11 | 11 | 16 | 16 |

True Tensile Strength @5% Strain | KN/m | 7 | 7 | 14 | 14 | 21 | 21 | 32 | 32 |

Junction Efficiency | % | 100 | 100 | 100 | 100 | ||||

Flexural Stiffness | mg-cm | 280.000 | 780,000 | 900,000 | 1,200,000 | ||||

Aperture Stability | kg-cm/deg | 3.1 | 4.8 | 4.3 | 3.4 | ||||

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | ||||

Resistance to Long Term Degradation | % | 100 | 100 | 100 | 100 | ||||

Unit Weight | g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | ||||

Rolls Dimensions (Length, Width) | m | 50×3.95 | 50×3.95 50X5 | 50×3.95 | 50×3.95 | ||||

Lading Capacity | Rolls/40HC | 300 | 260 | 140 | 100 | ||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the factors that affect the installation cost of geogrids?

- The factors that affect the installation cost of geogrids include the type and quality of the geogrid material, the size and complexity of the project area, the required preparation of the site, the method of installation (such as manual or mechanical), the labor and equipment costs, and any additional materials or accessories needed for proper installation.

- Q: Should the municipal geogrid be included in the area of overlap, and, if necessary, the proportion of the area to be included?

- The measurement of municipal geogrid shall not be included in the overlap area

- Q: The ground treatment is full of geogrid is not along the line direction

- Generally paved along the direction of the road

- Q: Can geogrids be used in railway track stabilization?

- Yes, geogrids can be used in railway track stabilization. Geogrids are commonly used in various civil engineering applications, including railway track stabilization, to improve the stability and performance of the tracks. They provide reinforcement and prevent lateral movement of the ballast, ensuring better load distribution and reducing track deformation.

- Q: Which is the most suitable for Highway Subgrade

- We are specializing in the production of geogrid. The words are basically according to design drawings, but if you use it, most or two-way plastic and steel grating, durable plastic relatively longer, of course, the price is higher; two-way plastic instead.

- Q: Physical characteristics of geogrid construction method

- 2, check the geogrid reinforced asphalt pavement or cement: Geogrid laying layer at the bottom of asphalt or cement, can reduce rutting depth, prolong the fatigue life of the pavement, but also can reduce the asphalt or cement pavement thickness, in order to save costs.3, one-way geogrid for reinforcing the dam and road slope and retaining wall: the traditional embankment especially filling high embankment filling and often need to shoulder edge easy compaction, resulting in slope rainwater invasion, collapse phenomenon, at the same time with a gentle slope, covers an area of large, retaining wall have the same problem with Geogrid embankment slope or retaining wall reinforcement can be reduced by two points a area, prolong service life, reduce the cost of 20 - 50%.4, one-way geogrid to reinforce the River seawall: made of stone cage, with the grid and use, prevent the dam washed collapse, stone cage is permeable and can reduce the impact of the waves, prolong the life of the dam, save manpower, shorten the construction period.5, one-way geogrid for processing landfills: Geogrid and other synthetic materials using a combination of Soil Treatment Landfill, can effectively solve the problem of gas emissions derived from the uneven settlement of foundation, and can improve the landfill to maximize storage capacity.6, one-way geogrid special purpose: low temperature resistance. Low temperature resistance of geogrid Lianyi, at - 45 C and 50 C - repeated 200 cycles, the performance indexes meet the requirements, and has been applied to the test of the Qinghai Tibet railway, the North less ice permafrost and ice rich permafrost and ice rich permafrost bad geology.

- Q: Which instrument is used to measure the permeability of geotextiles?

- Geotextile is a member of the geosynthetics, which is divided into the nonwoven geotextiles and geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention, protection, light weight, high tensile strength, good permeability, high temperature resistance, anti freezing, anti-aging, corrosion resistance. Non woven geotextile (polyester geotextile, non-woven geotextile), also known as geotextile, which is made of synthetic fibers by acupuncture or woven into the water permeability of Geosynthetics

- Q: How to distinguish the vertical and horizontal geogrid

- Generally do not distinguish between vertical and horizontal

- Q: What is the difference between polyethylene geogrid and uni directional high strength geogrid

- Purpose of service life. OneThe bidirectional grid is suitable for increasing the bearing capacity of the road (ground) base, and the service life of the Yan Changlu base. TwoThe utility model relates to a bidirectional grid which is suitable for preventing the collapse of the road surface and the generation of cracks.

- Q: How do geogrids improve the performance of reinforced soil retaining walls?

- Geogrids improve the performance of reinforced soil retaining walls by adding tensile strength and enhancing stability. They are typically made from high-strength materials such as polyester or polypropylene, which provide reinforcement to the soil mass. When geogrids are incorporated into the retaining wall design, they effectively distribute the applied loads, reducing the stress on the soil and preventing wall failure. Additionally, geogrids increase the overall stiffness of the reinforced soil, minimizing deformation and settlement. This reinforcement technique enables the construction of taller and more structurally sound retaining walls, ensuring long-term stability and improved performance.

Send your message to us

Geogride Stragrip Sg-150 Self-Adhesive Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords