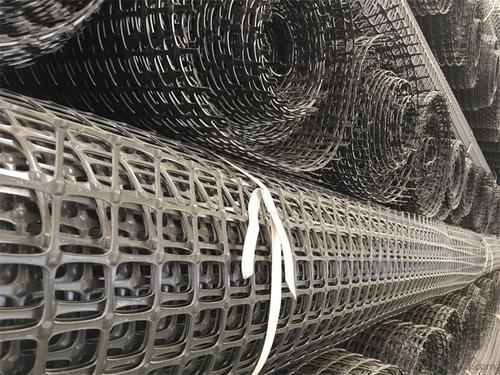

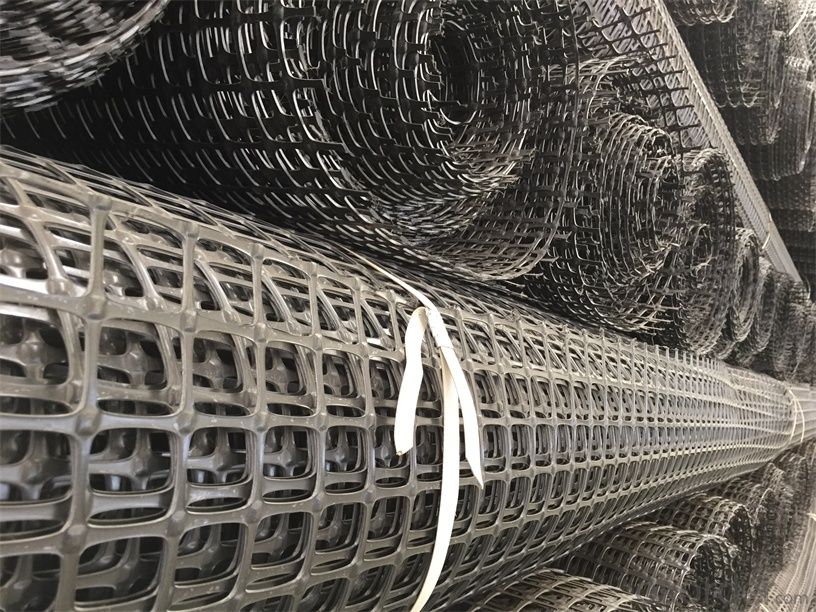

High Tensile Strength Black Uniaxial Geogrids for Roads

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: How are geogrids manufactured?

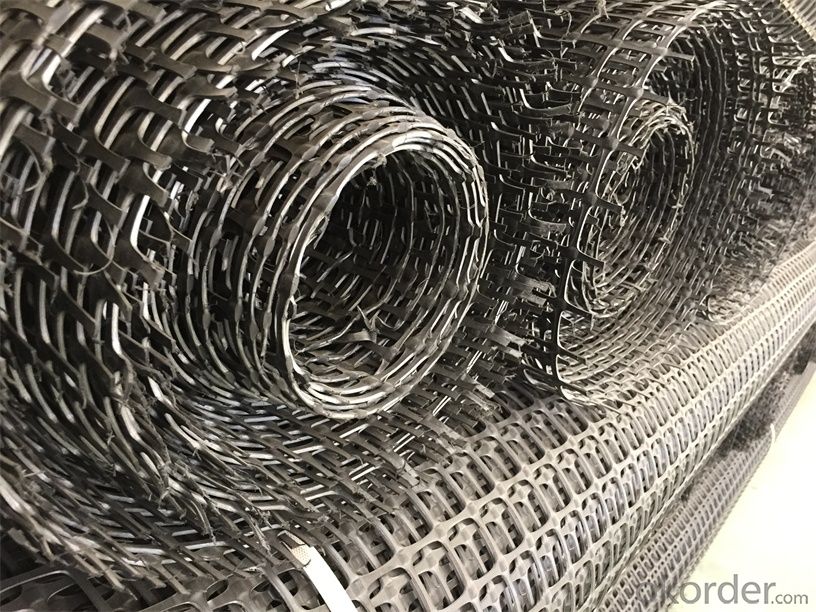

- Geogrids are manufactured through a process known as extrusion, where high-density polyethylene (HDPE) or polypropylene (PP) materials are melted and forced through a die to create a continuous mesh-like structure. This structure is then stretched in different directions to orient the polymer molecules, giving the geogrid its strength and stiffness. The material is then cooled, cut to the desired length, and rolled into large rolls for distribution and use in various geotechnical applications.

- Q: Do geogrids affect the permeability of soil?

- Yes, geogrids can affect the permeability of soil. Geogrids are commonly used as reinforcement materials in civil engineering projects to improve the stability and load-bearing capacity of soils. By distributing the applied loads over a larger area, geogrids reduce the pressure on the soil particles, which can minimize soil compaction and increase the void space within the soil. This can enhance the permeability of the soil, allowing water to flow more freely through it. Therefore, geogrids can have a positive impact on the permeability of soil.

- Q: What is the 110 type bidirectional geogrid?

- Geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching. It can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

- Q: Who knows the laying method of geogrid?

- The first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of Geogrid are folded up then fill in 0.1 meters (coarse) sand, prohibit filling and promote both sides to the middle, prohibit all mechanical without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand to prevent, level measurement, uneven fill thickness, to be leveling correct 25T vibratory roller pressure two times. (5) as the second layer of geogrid layer construction method with the first method, and finally filling in 0.3m (coarse sand), filling in the same way as the first layer, using 25T hydrostatic roller two times, so subgrade reinforcement is dealt with. (6) in the third layer (coarse sand) after rolling, along the line in the longitudinal slope on both sides of the geogrid two, overlapping 0.16m, and connected with the same method, and then start the earthwork construction work, laying geogrid in slope protection, each layer must measure the laying of lines, each side to ensure the slope renovation of geogrid buried in slope soil 0.10m. (7) when the geogrid is filled with two layers of soil, that is to say, the thickness of 0.8m is required to lay a layer of geogrid at the same time on both sides, and so on. (8) the Subgrade after timely slope renovation, and dry rubble slope protection, in addition to each side of the roadbed...

- Q: What is the recommended geogrid aperture size?

- The recommended geogrid aperture size depends on various factors such as the soil type, project requirements, and design specifications. It is typically determined through engineering analysis and testing to ensure optimal performance and stability.

- Q: The geogrid is not less than 3 meters on each side, what does it mean?

- At present, the largest width of single geogrid is 6 meters

- Q: Which kind of polypropylene geogrid belongs to the geogrid?,Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogridPlastic geogrid?

- Which kind of geogrid belongs to geogrid?Plastics geogrids divided tgsg and geogrid, geogrid and unidirectional polypropylene geogrid and unidirectional polyethylene geogrid, tgsg material is polypropylene;

- Q: Are geogrids suitable for erosion control on riverbanks?

- Yes, geogrids are suitable for erosion control on riverbanks. Geogrids provide stabilization and reinforcement to the soil, preventing erosion and maintaining the integrity of the riverbank. They are effective in withstanding the forces of water flow and offer long-term stability, making them an ideal solution for erosion control on riverbanks.

- Q: Can geogrids be used in mechanically stabilized earth walls?

- Yes, geogrids can be used in mechanically stabilized earth walls. Geogrids are commonly used as reinforcements in mechanically stabilized earth walls to improve their stability and strength. They effectively distribute the forces within the soil and reduce potential wall failure.

- Q: What are the advantages of using geogrids in ground improvement for slope stabilization?

- Geogrids offer several advantages in ground improvement for slope stabilization. Firstly, they provide enhanced soil reinforcement, increasing the overall strength and stability of the slope. This helps to prevent soil erosion and slope failure, reducing the risk of landslides. Additionally, geogrids distribute the applied loads more uniformly, which reduces the stress on the soil and prevents localized failures. They also improve the bearing capacity of the soil, allowing for the construction of structures or roads on slopes that would otherwise be unsuitable. Moreover, geogrids are lightweight and easy to install, making them a cost-effective and efficient solution for slope stabilization projects.

Send your message to us

High Tensile Strength Black Uniaxial Geogrids for Roads

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords