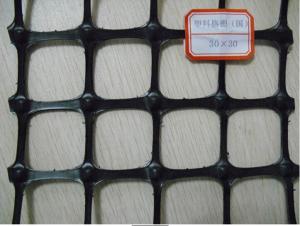

Woven Polyester Geogrids Geocomposite Geomembrane for Rock Fill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The description of Geocomposite Geomembrane for Rock fill dam and transportation tunnel

Made by non woven geotextile and PE/PVC geomembrane. Categories are including geotextile and geomembrane, geomembrane with non woven geotextile on both sides, non woven geotex-tile with geomembrane on both sides, multi-layer geotextile and geomembrane.

Specification of eocomposite Geomembrane for Rock fill dam and transportation tunnel:

L. One geotextile and one geotextile, geotextile: 100 - 800g/m', geomembrane O. 1-I. Omm.

2. Geomembrane with geotextile on both sides: Geotextile 100 - 400G/M2; Geomembrane: 0.2 - l. Omm

3. Geotextile with geomembrane on both sides: Geotextile 100 - 800G/M2; Geomembrane: 0.1- 0.8mm

Features or Property of Geocomposite Geomembrane for Rock fill dam and transportation tunnel:

L. Good flexibility

2. Separation, reinforcement and protection

3. Waterproofing

Application of Geocomposite Geomembrane for Rock fill dam and transportation tunnel:

L. Reinforcement in channel

2. Embankment, reservoir

3. Waterproofing in reservoir

4. Rock fill dam and transportation tunnel

Production Standard of Geocomposite Geomembrane for Rock fill dam and transportation tunnel:

GB/T17642-2008

Area |

|

Hydraulic | Lagooning and Water Treatment, Ornamental Ponds, Golf Courses Aquaculture and Desalination Water LagoonsTanks, Reservoirs, Liquid WasteFloating Cover SolutionsDrainage and FiltrationShading Cover Solutions |

Environment | Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers |

- Q: What are the advantages of using geogrids in mechanically stabilized aggregate bases?

- Some advantages of using geogrids in mechanically stabilized aggregate bases include increased load-bearing capacity, improved stability and performance, reduced construction and maintenance costs, and enhanced longevity of the pavement structure. Geogrids distribute and restrain the applied loads more evenly, reducing the stress on the underlying soil and aggregate layers. This results in higher load-bearing capacity and improved resistance against settlement, rutting, and pavement deformation. Additionally, geogrids help in maintaining the integrity of the aggregate base by preventing lateral spreading and enhancing interlocking between the aggregate particles. The use of geogrids also reduces the amount of aggregate material required for construction, leading to cost savings. Moreover, the improved stability provided by geogrids can extend the lifespan of the pavement structure, reducing the need for frequent maintenance and repairs.

- Q: meters. Material: tgsg. This section of subgrade for soft soil foundation (water) what is the purpose and principle of this treatment? Seeking answers experienced master change, or in the design the unit did. Thank you. Do a detailed description of indebted forever. My understanding is...Geogrid width of 3 meters, the berm soil subgrade body laying 1.4 meters, laying 1.6

- Do you understand the true role of geogrid?

- Q: Can geogrids be used in railway track stabilization?

- Yes, geogrids can be used in railway track stabilization. Geogrids are commonly used in civil engineering projects to improve soil stability, reinforce weak subgrades, and minimize lateral movement. In railway track stabilization, geogrids can be installed beneath the ballast layer to enhance load distribution, reduce track settlement, and increase the overall strength of the track system.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in sandy soils?

- Geogrids improve the performance of mechanically stabilized slopes in sandy soils by providing additional reinforcement and stability. They are typically made of high-strength polymer materials and are placed within the soil to distribute loads and increase the overall strength of the slope. The geogrids act as a barrier, preventing the movement of soil particles and reducing the risk of erosion. This reinforcement helps to maintain the integrity of the slope, preventing it from sliding or collapsing. Additionally, geogrids can enhance the overall lifespan of the slope by reducing the stress on the soil and mitigating the effects of settlement.

- Q: How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing additional strength, stability, and reinforcement to the structure. They help distribute and transfer the loads more efficiently, improving the overall stability and resistance to deformation of the geotextile tubes.

- Q: Are geogrids suitable for use in reinforced slopes?

- Yes, geogrids are generally suitable for use in reinforced slopes. They provide strength and stability to the soil, reducing the risk of slope failure and erosion. Geogrids improve the load-bearing capacity of the slope, distribute stresses more evenly, and enhance the overall performance and longevity of the slope reinforcement system.

- Q: How do geogrids help in reducing construction material consumption?

- Geogrids help in reducing construction material consumption by providing reinforcement and stabilization to soil or aggregates, allowing for the use of thinner layers of materials. This reduces the overall amount of materials required for construction, leading to cost savings and more sustainable practices.

- Q: Can geogrids be used in underground mining applications?

- Yes, geogrids can be used in underground mining applications. Geogrids are commonly used in mining operations for reinforcement and stabilization of soil or rock structures. They provide support to prevent soil or rock movement, enhance load distribution, and improve overall stability in underground mining operations.

- Q: What is the recommended installation method for geogrids?

- The recommended installation method for geogrids is to ensure proper preparation of the subgrade, followed by unrolling the geogrid on top and securing it with stakes or pins. It is important to overlap the geogrid panels correctly and avoid any wrinkles or folds. Finally, cover the geogrid with the desired fill material and compact it properly to maximize the effectiveness of the geogrid.

- Q: What is the effect of confinement on geogrid performance?

- The effect of confinement on geogrid performance is generally positive. Confinement helps improve the stability and load-bearing capacity of geogrids by restraining lateral movement and enhancing soil-geogrid interaction. It prevents the geogrid from elongating or deforming under heavy loads, leading to better reinforcement and increased structural integrity. Confinement also reduces the potential for geogrids to slip or creep, improving their long-term performance and durability.

Send your message to us

Woven Polyester Geogrids Geocomposite Geomembrane for Rock Fill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords