Geocells Suppliers UK - Self-Adhesive Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

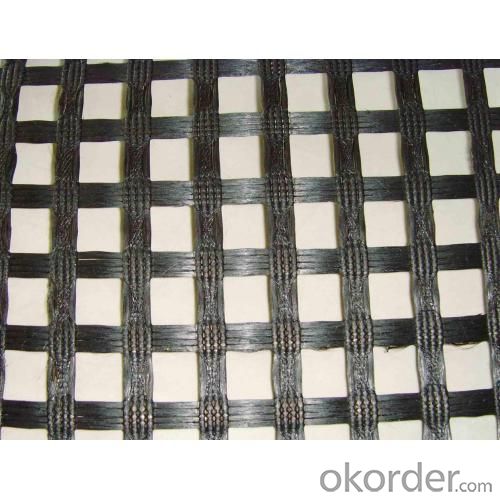

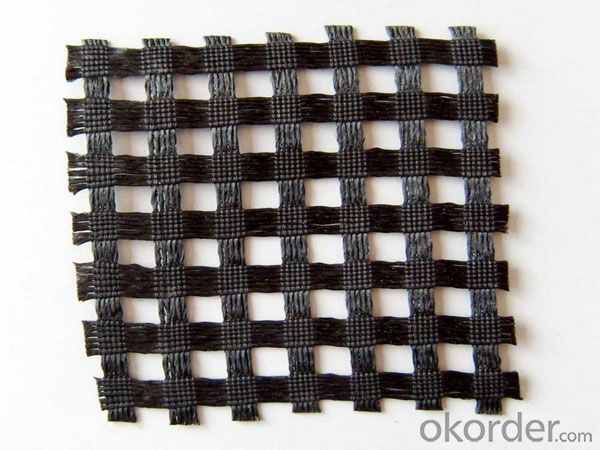

Structure of Self-adhesive Fiberglass Geogrid Description:

Self-adhesive Fiberglass Geogrid is a kind of reinforcement product, which uses the anti-acid& alkali basalt continuous filament (BCF) to produce gridding base material with advanced knitting process, sized with silane and coated with PVC. The stable physical properties make it both high and low temperature resistant and highly resistant to deformation.

Main Features of Self-adhesive Fiberglass Geogrid:

Can be used under super-low tmperature and have good thrmal stability.

High tensile strength and low elongation

Good physical and chemical stability, strong resistance to biological erosion and climate changes

Could replace steel-plastic geogrid in coal mine.

Self-adhesive Fiberglass Geogrid Images

Self-adhesive Fiberglass Geogrid Specification:

| Item | Width (mm) | Thickness (mm) | Surface Weight (g/m2) | Breaking Strength (N/5cm ) | Elongation at Break(%) | Breaking Elongation (mm) | |||

| Basalt Fiber Geogrid | 1000±30 | 0.8-0.9 | 303 ±15.15 | Warp | Weft | Warp | Weft | Warp | Weft |

| 3038.86 ±151.943 | 2688.86 ±134.443 | 6.67 ±0.3335 | 3.53 ±0.1765 | 13.34 ±0.667 | 7.07 ±0.3535 | ||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Are geogrids resistant to puncture?

- Yes, geogrids are generally resistant to puncture due to their high tensile strength and durability. They are designed to withstand puncture forces from sharp objects or heavy loads, making them suitable for various applications in civil engineering and construction projects.

- Q: Geosynthetic materials for flood control materials

- Such SPE.Shows that a large number of engineering practice, geomembrane impervious good, general permeability coefficient K =10cm/s ~ 10cm/s; has great flexibility and adaptability to deformation ability; have good aging ability, under water, water is more durable. According to the anti aging test, it can be concluded that the service life of the polymer geomembrane buried in soil and water can be up to 50 years, and the service life of the high-density geomembrane in the dam is more than 100 years. Mainly made of geogrid, geogrid, belt, soil gabion, geotextile tube, geotextile bag, Geomat, EPS, geocell and so on, it is used for soil reinforcement and reinforcement. Such as the reinforcement of soft soil foundation, steep slope, retaining structure built in the stable foundation, embankment collapse rescue.

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications varies depending on the specific requirements of the project. However, commonly used shapes include square, rectangular, and hexagonal apertures. These shapes provide different levels of stability, soil confinement, and load distribution, allowing engineers to select the most suitable option based on factors such as soil type, slope angle, and anticipated loads.

- Q: What are the different materials used to manufacture geogrids?

- Geogrids are manufactured using various materials such as polyester, polypropylene, high-density polyethylene (HDPE), and fiberglass. These materials offer different strengths, durability, and chemical resistances, allowing geogrids to be customized for various applications in civil engineering and construction projects.

- Q: How do geogrids help in reducing construction costs?

- Geogrids help in reducing construction costs by providing reinforcement and stabilization to the soil, allowing for the use of less expensive and lower-quality fill materials. Additionally, they increase the load-bearing capacity of the soil, reducing the need for extensive excavation and costly foundation construction. Geogrids also minimize the risk of soil erosion, which can lead to costly repairs and maintenance. Overall, geogrids offer a cost-effective solution for improving soil stability and reducing construction expenses.

- Q: Polypropylene geogrid

- Of course, geogrid has HDPE material, this subtle geogrid is heard, I also do the geogrid distribution for 6 years, general polypropylene geogrid, geogrid is bidirectional and unidirectional geogrid, the hope can help you,

- Q: Are geogrids resistant to microbial attack?

- Yes, geogrids are typically resistant to microbial attack.

- Q: How do geogrids enhance the stability of landfill slopes?

- Geogrids enhance the stability of landfill slopes by creating a reinforced structure that prevents soil erosion and slope failures. They provide additional tensile strength to the soil, distribute lateral loads more evenly, and increase overall slope stability. Additionally, geogrids help to control soil settlement and improve drainage, reducing the risk of landslides and ensuring long-term stability of the landfill slopes.

- Q: How do geogrids improve the performance of geosynthetic clay liners?

- Geogrids improve the performance of geosynthetic clay liners by enhancing their tensile strength and reducing lateral movement or deformation. The geogrids act as a reinforcement layer, providing additional stability and support to the clay liner. This helps to prevent cracking, shifting, and erosion of the liner, ultimately enhancing its overall performance and durability.

- Q: How do geogrids help in reducing the carbon footprint of a project?

- Geogrids help in reducing the carbon footprint of a project by providing a sustainable and environmentally-friendly solution for soil stabilization and reinforcement. By using geogrids, less excavation and material are required, reducing the need for transportation and minimizing energy consumption. Additionally, geogrids can extend the lifespan of infrastructure, reducing the need for frequent repairs and replacements, which further reduces carbon emissions associated with construction.

Send your message to us

Geocells Suppliers UK - Self-Adhesive Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords