Geogride Stragrip Sg-150 Self-Adhesive Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

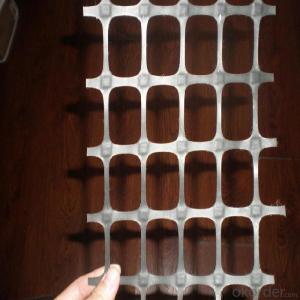

Structure of Self-Adhesive Fiberglass Geogrid Description:

Self-Adhesive Fiberglass Geogrid can be used to enhancement of permanent bearable toft including roads and railways embankment, slopes, tunnel, airfields, parks, docks and ground which cargo lays on and their main usage

Main Features of Self-Adhesive Fiberglass Geogrid:

1.Enhance the bearing capacity of road foundation and extend the duration of roads.

2.Prevent road surface from collapse, crack and being dirty.

3.Be convenient for construction, timesaving and cut down the cost of maintenance.

4.Prevent tunnel from crack occurring.

5.Further solidity slopes to proof water and soil from losses.

6.Reduce the surface thickness of the ground.

Self-Adhesive Fiberglass Geogrid Images

Self-Adhesive Fiberglass Geogrid Specification:

Item | TGSG15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | |||||

Unit | MD | CD | MD | CD | MD | CD | MD | CD | |

True initial Modulus in Use | KN/m | 15 | 15 | 20 | 20 | 30 | 30 | 40 | 40 |

True Tensile Strength @2% Strain | KN/m | 5 | 5 | 7 | 7 | 11 | 11 | 16 | 16 |

True Tensile Strength @5% Strain | KN/m | 7 | 7 | 14 | 14 | 21 | 21 | 32 | 32 |

Junction Efficiency | % | 100 | 100 | 100 | 100 | ||||

Flexural Stiffness | mg-cm | 280.000 | 780,000 | 900,000 | 1,200,000 | ||||

Aperture Stability | kg-cm/deg | 3.1 | 4.8 | 4.3 | 3.4 | ||||

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | ||||

Resistance to Long Term Degradation | % | 100 | 100 | 100 | 100 | ||||

Unit Weight | g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | ||||

Rolls Dimensions (Length, Width) | m | 50×3.95 | 50×3.95 50X5 | 50×3.95 | 50×3.95 | ||||

Lading Capacity | Rolls/40HC | 300 | 260 | 140 | 100 | ||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: I am a quality inspector, I would like to know what is the standard implementation of Geogrid

- 4:YT030 geotextile effective aperture measuring instrument5:YT040 type dynamic testing instrument for geotextiles6:YT050 type geotextile wear tester

- Q: How do geogrids improve the bearing capacity of foundations?

- Geogrids improve the bearing capacity of foundations by increasing soil stability and reinforcement. They act as a mesh or lattice-like structure that is placed within the soil, distributing the load more evenly and preventing soil from shifting or settling. This helps to reduce settlement and improve the overall strength and stability of the foundation.

- Q: Are geogrids resistant to UV degradation?

- Yes, geogrids are typically resistant to UV degradation. They are often manufactured using materials that have been treated or designed to withstand exposure to ultraviolet (UV) rays from the sun, ensuring their durability and longevity in outdoor applications.

- Q: Introduction of steel plastic grille

- Construction technology of steel plastic grille

- Q: Are geogrids resistant to aging?

- Yes, geogrids are generally resistant to aging. They are designed to withstand long-term exposure to environmental factors such as UV radiation, temperature fluctuations, and chemical exposure, which helps to maintain their strength and durability over time.

- Q: Can geogrids be used in streambank stabilization applications?

- Yes, geogrids can be used in streambank stabilization applications. Geogrids are commonly used in these applications to reinforce and stabilize slopes and banks, preventing erosion and soil movement. They provide strength and support to the soil, allowing vegetation to establish and grow, further enhancing the stability of the streambank.

- Q: Can geogrids be used in soil reinforcement for load-bearing platforms?

- Yes, geogrids can be used in soil reinforcement for load-bearing platforms. Geogrids are commonly used in civil engineering projects to improve the stability and strength of soil. They are effective in distributing loads, reducing soil settlement, and preventing soil erosion, making them suitable for reinforcing load-bearing platforms.

- Q: Can geogrids be used in reinforcement of underground parking structures?

- Yes, geogrids can be used in the reinforcement of underground parking structures. Geogrids are commonly used to provide stability and support to soil and rock structures. In underground parking structures, they can be used to reinforce the soil and prevent movement or collapse, ensuring the safety and longevity of the structure.

- Q: What are the long-term durability characteristics of geogrids?

- Geogrids have excellent long-term durability characteristics. They are designed to withstand harsh environmental conditions, including high temperatures, moisture, and chemical exposure. Geogrids are made from high-strength materials, such as polyester or polypropylene, which provide resistance against degradation and maintain their structural integrity over time. They have a long service life and can effectively retain soil, stabilize slopes, and reinforce paved surfaces for many years without significant deterioration.

- Q: How do geogrids enhance the stability of steep railway embankments?

- Geogrids enhance the stability of steep railway embankments by providing reinforcement and confinement to the soil. They are placed within the embankment, creating a strong and stable structure that can withstand the forces of gravity and lateral movements. Geogrids distribute the load more evenly, reducing the risk of slope failure and erosion. Additionally, they improve the shear strength of the embankment, preventing soil movement and ensuring long-term stability.

Send your message to us

Geogride Stragrip Sg-150 Self-Adhesive Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords