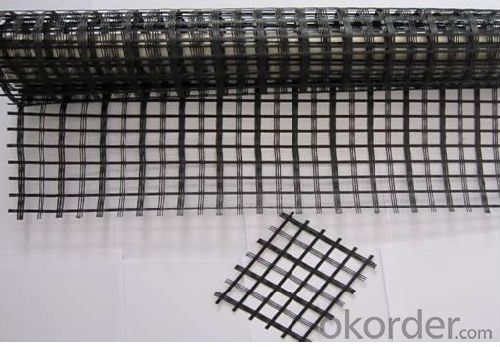

Geocells for Driveways - Fiberglass Geogrid with Good Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

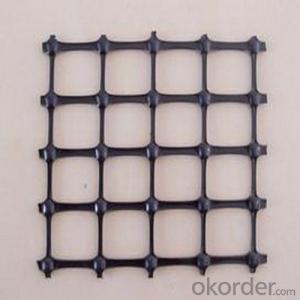

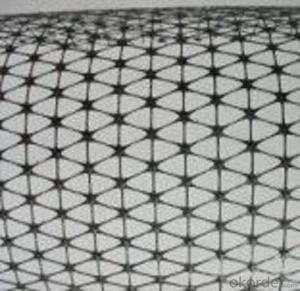

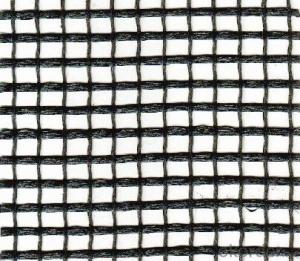

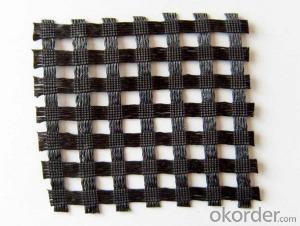

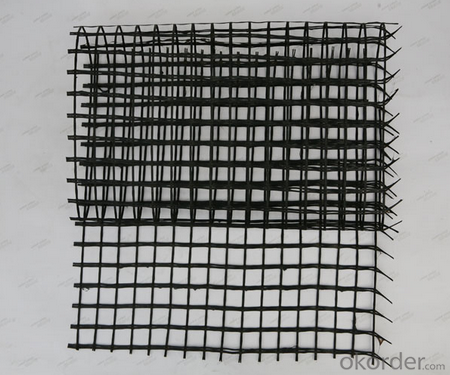

composite geogrid is made by blending high tensile steel wire which is specially processed and polyethylene (P.E.), and adds other accessory ingredients and though squeezing out to make it become complex belt that gas good tension resistance, and the surface ha rough embossing, which makes the reinforced geosynthetics belt. Based on the single belt and arranged by knitting or clamping vertically and horizontally according to certain space and fused on their connection points by using specially reinforced fusion-jointing technique, which makes the reinforced geogrid.

Performance

High intensity and small distortion

Slow creep

Anti-corrosive, long-term service life, steel plastic geogrid material with steel plastic material as its protector, and with various accessory ingredients to make the product have the abilities if anti-aging and anti-oxidation resisting permant project more than 100 years, and the performance is superior, the size stability is good.

The construction is convenient, the cycle is short, the cost is low; it is easy to lay down, join, locate, avoids overlapping cross over, but reduces the project cycle effectively, saves the building cost of projects by 10%--50%.

Application

The products are applied widely in railway, bridge, dock, retaining wall, dam ti reinforce the soft soil’s foundation and to resist the road surface’s crack.

Specifications

The high-strength One-way (vertical) Geogrid

Item | GSZ30 | GSZ50 | GSZ80 | GSZ100 | GSZ120 | GSZ150 |

Vertical limit-tensile strength KN/m ≥ | 30 | 50 | 80 | 100 | 120 | 150 |

Vertical limit elongation(%)≤ | 3 | |||||

The tensile strength of elongation at 1%KN/m ≥ | 23 | 38 | 63 | 81 | 98 | 125 |

The high-strength steel-plastic Two-way (vertical and horizontally) Geogrid

Item | GSZ30-30 | GSZ45-45 | GSZ60-60 | GSZ80-80 | GSZ100-100 | GSZ120-120 |

Biaxial ultimate tension KN/m ≥ | 30 | 45 | 60 | 80 | 100 | 120 |

Biaxial ultimate elongation (%)≤ | 3 | |||||

The tensile strength of elongationat 1% KN/m ≥ | 23 | 36 | 48 | 63 | 81 | 98 |

Packaging and storage

The Steel plastic composite geogrid, the length of the product roll is decided by the construction requests. The rolls are to be horizontally placed and not more than 6 layers high.

Unless otherwise specified, the production should be stored in a non-corrosive gas, non-dust, well-ventilated, dry and rainproof area.

It is recommended that the room temperature should be maintained below 35°C,and humidity should be always maintained below 65%

- Q: What kind of circumstances need to shop geogrid

- In the treatment of bad foundation, or the transformation of the old road, geogrid can quickly improve the bearing capacity of the foundation, speed up the progress of construction; control of soft ground settlement development, shorten the construction period, so that the early use of the road.

- Q: Are there any limitations or drawbacks of using geogrids?

- Yes, there are limitations and drawbacks to using geogrids. Some of the limitations include the need for proper installation and compaction to achieve desired performance, as well as the requirement for an appropriate soil structure to effectively interlock with the geogrid. Additionally, geogrids may not be suitable for certain soil types, such as highly compressible or expansive soils. Other drawbacks include potential damage during installation, high cost compared to conventional soil reinforcement methods, and potential long-term degradation due to environmental factors.

- Q: What is the recommended geogrid roll width for specific applications?

- The recommended geogrid roll width for specific applications can vary depending on factors such as soil conditions, load requirements, and project specifications. It is best to consult with a geotechnical engineer or geosynthetics expert to determine the appropriate geogrid roll width for your specific application.

- Q: How do geogrids help in reducing maintenance costs?

- Geogrids help in reducing maintenance costs by providing reinforcement to the soil, increasing its stability and load-bearing capacity. This prevents the need for frequent repairs and maintenance due to soil erosion, settlement, or structural failures. Geogrids also improve drainage, reducing the accumulation of water and preventing damage to the infrastructure, thereby minimizing maintenance expenses in the long run.

- Q: What is the width of glass fiber grating 100cm

- 1 meters wide,???? Is there anything to ask

- Q: Technical specifications of glass fiber grating

- Specification EGA1 * 1A-N EGA1 * 1CA-N EGA1 * 2A-N EGA2 * 2C-N EGA1 * 1A EGA1 * 1CA EGA1 * 1B EGA2 * 2A EGA2 * 2CA * 2B fracture strength of EGA1 * EGA2 * EGA2 * 2B-N * 1B-N * 1C * EGA2 *

- Q: Are geogrids suitable for use in mine tailings containment?

- Yes, geogrids are suitable for use in mine tailings containment. Geogrids are commonly used in various civil engineering applications, including mine tailings containment, due to their high tensile strength, durability, and ability to reinforce soil. They can effectively stabilize and reinforce the tailings, preventing slope failures and controlling erosion. Additionally, geogrids can enhance the overall stability and longevity of the containment system, making them a reliable choice for mine tailings management.

- Q: What are the cost considerations for using geogrids in construction projects?

- Some cost considerations for using geogrids in construction projects include the initial cost of purchasing and installing the geogrids, the potential cost savings in reducing the amount of traditional materials needed, the cost of maintenance and repair over time, and the overall long-term cost-effectiveness compared to alternative construction methods.

- Q: How do geogrids enhance the stability of railway track embankments?

- Geogrids enhance the stability of railway track embankments by providing reinforcement and preventing soil erosion. They are placed within the embankment layers, creating a strong and stable foundation. The geogrids distribute the load from the trains more evenly, reducing settlement and the risk of track deformation. Additionally, they improve drainage and prevent water accumulation, which can weaken the embankment structure. Overall, geogrids increase the longevity and performance of railway track embankments by enhancing their stability and reducing maintenance needs.

- Q: What is the calculation method of geogrid?

- Geogrid width is the most commonly used 4 meters, the length of a roll is commonly used in the 50 meters, 100 meters; the thickness of the grid is uncertain,

Send your message to us

Geocells for Driveways - Fiberglass Geogrid with Good Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords