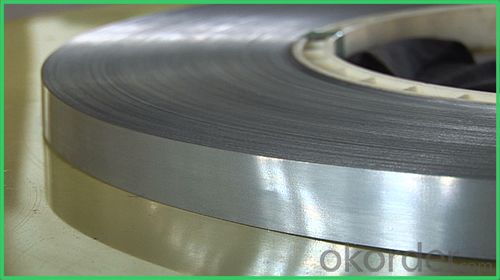

GCr15 Bearing Steel Special Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Bearing Steelsat great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

.

Product Advantages:

OKorder's Bearing Steels are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Packaging & Delivery of Bearing Steel GCr15

Mark: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted.

Standard seaworthy packing or as customer required

Delivery time: Within 30 days after order is confirmed.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the different methods of surface hardening for special steel?

- There are several methods of surface hardening for special steel, including carburizing, nitriding, induction hardening, flame hardening, and laser hardening.

- Q: How does special steel contribute to the manufacturing of medical implants?

- Special steel plays a vital role in the manufacturing of medical implants by offering superior strength, corrosion resistance, and biocompatibility. These properties are crucial for ensuring the longevity and functionality of implants, allowing them to withstand the harsh conditions within the human body. Additionally, special steel can be shaped and machined into complex forms, enabling the production of intricate and customized implants to meet the specific needs of patients. Overall, special steel is essential for producing high-quality and reliable medical implants that enhance patient outcomes and improve their quality of life.

- Q: What are the different methods of surface thermal spraying for special steel?

- There are several different methods of surface thermal spraying for special steel, including flame spraying, arc spraying, plasma spraying, and high-velocity oxy-fuel (HVOF) spraying. Each method involves heating and melting a coating material, which is then propelled onto the steel surface to form a protective layer. These methods offer varying levels of coating thickness, adhesion, and durability, depending on the specific requirements of the application.

- Q: How is high-strength alloy steel used in the production of structural components?

- High-strength alloy steel is commonly used in the production of structural components due to its exceptional strength-to-weight ratio and durability. It provides the necessary strength and stability required for structural applications, such as bridges, buildings, and infrastructure. The high-strength properties of alloy steel allow for the creation of lighter and more efficient structures, reducing material and construction costs while ensuring structural integrity and safety.

- Q: What are the properties of magnesium alloys?

- Magnesium alloys are known for their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. They have good heat dissipation capabilities, making them suitable for applications in the automotive and aerospace industries. Additionally, magnesium alloys exhibit good machinability, electromagnetic shielding, and damping properties, making them versatile for various engineering applications.

- Q: What are the different methods of measuring the hardness of special steel?

- There are several methods available for measuring the hardness of special steel. These methods can be categorized into two main categories: destructive and non-destructive testing. 1. Rockwell Hardness Test: This is a widely used destructive testing method that measures the depth of penetration of an indenter into the steel surface. The Rockwell hardness test provides a hardness value based on the resistance of the steel to indentation. It is a simple and quick method that requires minimal sample preparation. 2. Brinell Hardness Test: Another destructive testing method, the Brinell hardness test, involves applying a known load to a hardened steel ball and measuring the diameter of the indentation left on the steel surface. The hardness value is determined based on the ratio of the applied load to the surface area of the indentation. 3. Vickers Hardness Test: This is a micro-indentation test that utilizes a diamond pyramid-shaped indenter. The Vickers hardness test measures the diagonal length of the indentation left on the steel surface and calculates the hardness value based on the applied load. 4. Knoop Hardness Test: Similar to the Vickers test, the Knoop hardness test is a micro-indentation method that uses a diamond pyramid-shaped indenter. However, instead of measuring the diagonal length of the indentation, it measures the length of the long axis. This test is particularly useful for measuring the hardness of thin steel samples or steel coatings. 5. Ultrasonic Hardness Test: This non-destructive testing method measures the hardness of steel by analyzing the propagation of ultrasonic waves through the material. The hardness value is determined based on the correlation between the velocity of the waves and the hardness of the steel. 6. Magnetic Hardness Test: This non-destructive testing method utilizes magnetic properties to measure the hardness of steel. It involves applying a magnetic field to the steel and measuring the magnetic response. The hardness value is determined based on the correlation between the magnetic response and the hardness of the steel. It is important to note that each method has its advantages and limitations, and the choice of method depends on factors such as the type of steel, the required accuracy, the sample size, and the available equipment and expertise.

- Q: What are the main characteristics of creep-resistant steel?

- Creep-resistant steel possesses high strength and resistance to deformation at elevated temperatures. It maintains its mechanical properties even under long-term exposure to high stress and high temperatures. Its ability to resist creep, or the gradual deformation under stress, makes it suitable for applications in power plants, boilers, and other high-temperature environments. Additionally, creep-resistant steel exhibits good resistance to corrosion and oxidation, ensuring its durability and longevity in harsh conditions.

- Q: How is maraging steel used in the production of rocket and missile components?

- Maraging steel is commonly used in the production of rocket and missile components due to its exceptional strength, toughness, and resistance to corrosion. Its unique properties allow for the creation of lightweight yet highly durable parts, such as rocket nozzles, casings, and guidance systems. Additionally, maraging steel can withstand extreme temperatures and pressures, making it suitable for the demanding conditions of space and military applications.

- Q: How does special steel perform in terms of machinability?

- Special steel typically has good machinability due to its composition and specific manufacturing processes. It is often designed to have improved cutting and chip formation properties, allowing for easier and more efficient machining operations. This allows manufacturers to achieve high precision and productivity when working with special steel, making it a favorable choice for various applications.

- Q: How is high-speed tool steel used in the production of machining tools?

- High-speed tool steel is used in the production of machining tools due to its exceptional hardness and ability to retain its cutting edge even at high temperatures. This steel is used to create tool bits, inserts, and drill bits that are capable of withstanding the high speeds and forces involved in machining processes. Its high wear resistance and heat resistance properties make it an ideal choice for manufacturing cutting tools that can efficiently shape and form various materials during machining operations.

Send your message to us

GCr15 Bearing Steel Special Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords