GB Standard Steel H Beam 294mm-346mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 294mm-346mm with High Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 294*302*12.0 | 83.4 | 300*305*15.0 | 105 |

| 300*300*10.0 | 93.0 | 346*174*6.0 | 41.2 |

Usage & Applications of GB Standard Steel H Beam 294mm-346mm with High Quality For Sale:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of GB Standard Steel H Beam 294mm-346mm with High Quality for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truc4. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

4. Delivered by 40' GP/HP container or bulk vessel.

Production flow of GB Standard Steel H Beam 294mm-346mm with High Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

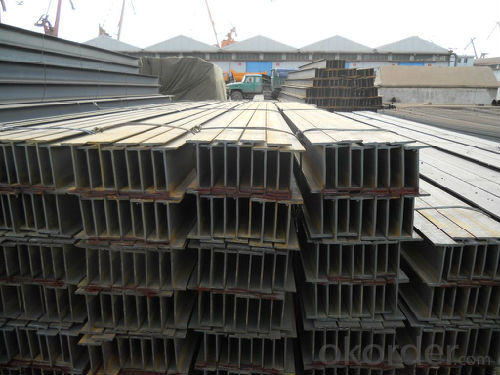

Images of GB Standard Steel H Beam 294mm-346mm with High Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What is the weight of a typical steel H-beam?

- The weight of a typical steel H-beam can vary depending on its size and dimensions. However, as a general guideline, an H-beam weighing around 33 pounds per foot (or approximately 49 kilograms per meter) is considered typical. It is important to note that the weight can vary based on factors such as the specific alloy of steel used, the manufacturing process, and any additional modifications or treatments applied to the H-beam. For accurate and precise weight information, it is recommended to refer to the manufacturer's specifications or consult with a structural engineer.

- Q: What are the common factors that affect the cost of steel H-beams?

- The cost of steel H-beams can be affected by a multitude of factors. These factors include: 1. Raw material costs: The prices of the raw materials used to produce steel H-beams, such as iron ore and coal, can have a significant impact on the overall cost. Fluctuations in these material prices directly influence production costs and subsequently the selling price of the H-beams. 2. Manufacturing process: The manufacturing process of steel H-beams involves several stages, including melting, casting, rolling, and heat treatment. The efficiency and complexity of these processes can impact the cost. Technological advancements, energy consumption, labor costs, and equipment maintenance expenses all contribute to determining the overall manufacturing cost. 3. Market demand and supply: The demand and supply dynamics of steel H-beams can influence their cost. When demand is high and supply is limited, prices tend to be higher. Conversely, when demand is low and supply is excessive, prices may decrease. Factors such as market conditions, construction projects, and economic conditions all affect the demand and supply of steel H-beams. 4. Transport and logistics: The cost of transporting steel H-beams from the manufacturing facility to the customer's location can impact the final price. Factors such as distance, transportation methods, fuel prices, and handling charges all contribute to the overall cost. Additionally, import duties, taxes, and tariffs imposed by different countries can also affect the cost of steel H-beams. 5. Quality and specifications: The quality and specifications of steel H-beams can influence their cost. Higher-quality materials, superior finishes, and precise dimensions can result in higher prices. Furthermore, specific requirements such as custom sizes, lengths, or special coatings can increase production costs and, subsequently, the selling price. 6. Competition and market conditions: The level of competition in the steel industry can influence the cost of H-beams. Intense competition among manufacturers can lead to price wars and lower prices. Economic factors, global trade policies, and market trends also impact the cost of steel H-beams. It is essential to note that these factors may vary depending on geographic location, industry-specific requirements, and other external factors. As a result, the cost of steel H-beams can fluctuate over time due to changes in any or all of these factors.

- Q: What is the load-bearing capacity of H steel spans 6 meters and 300 * 300? How is it calculated?

- Unable to bear too much weight. It is recommended to use more than 600*300*12*18 H steel.

- Q: Can steel H-beams be used for supporting mining infrastructure?

- Yes, steel H-beams can be used for supporting mining infrastructure. H-beams are commonly used in construction and civil engineering projects due to their strength and versatility. They are designed to withstand heavy loads and provide structural support, making them suitable for use in mining infrastructure. The mining industry often requires robust support systems to ensure the stability and safety of underground tunnels, shafts, and other mining structures. Steel H-beams are ideal for this purpose as they offer high load-bearing capacity and resistance to bending, making them capable of withstanding the challenging conditions found in mining environments. Additionally, steel H-beams can be easily customized to meet specific project requirements. They can be cut to various lengths and welded together to form larger structural elements, allowing for the creation of complex support systems tailored to the unique needs of mining infrastructure. Furthermore, steel H-beams are durable and have a long lifespan, reducing the need for frequent maintenance or replacement. This is particularly important in the mining industry, where downtime and maintenance costs can significantly impact productivity and profitability. In summary, steel H-beams are a suitable choice for supporting mining infrastructure due to their strength, versatility, and durability. They provide the necessary support and stability required in mining environments, making them an excellent option for constructing and reinforcing underground mining structures.

- Q: What are the common connection methods for steel H-beams?

- The common connection methods for steel H-beams include welding, bolting, and using mechanical connections such as clips or brackets. Welding is the most common method and involves fusing the beams together using heat and filler material to create a strong, permanent connection. Bolting is another popular method, where steel plates are drilled and bolted onto the flanges of the H-beams to hold them together. This method allows for easier disassembly or modification if needed. Mechanical connections, such as clips or brackets, are often used for temporary or adjustable connections and provide a quick and easy way to connect H-beams without the need for welding or drilling. These connections are usually used for lighter loads or non-structural applications. Ultimately, the choice of connection method depends on the specific requirements of the project, such as load capacity, ease of installation, and the need for future modifications.

- Q: Can steel H-beams be used in railway or subway construction?

- Railway or subway construction can certainly utilize steel H-beams. These beams, also known as I-beams, are extensively used in the construction industry due to their robustness and durability. They are commonly employed as load-bearing components in various structures, such as bridges, buildings, and railway or subway tracks. When it comes to railway or subway construction, steel H-beams are typically utilized as support beams for elevated tracks or platforms. These beams play a crucial role in providing the required structural integrity and stability to bear the weight of trains and passengers. They are specifically designed to withstand heavy loads and high pressure, ensuring the safety and dependability of the railway or subway system. Steel H-beams offer several advantages for railway or subway construction. Firstly, their strength-to-weight ratio is high, allowing them to support heavy loads while being comparatively lightweight themselves. This aspect is extremely important in railway or subway construction as it enables the efficient utilization of materials and reduces the overall weight of the structure. Furthermore, steel H-beams possess resistance against deformation and corrosion, rendering them suitable for long-term usage in outdoor and underground environments. They are capable of enduring the harsh conditions associated with railway or subway systems, including exposure to weather, vibrations, and moisture. Moreover, steel H-beams are easily accessible and cost-effective, making them the preferred choice for construction projects. They can be manufactured, transported, and installed with ease, saving both time and resources during the construction process. To conclude, steel H-beams are extensively employed in railway or subway construction due to their strength, durability, and cost-effectiveness. They provide the necessary support and stability for elevated tracks or platforms, ensuring the safety and reliability of the transportation system.

- Q: How do steel H-beams perform in areas with high levels of humidity or moisture?

- Steel H-beams perform well in areas with high levels of humidity or moisture due to their corrosion-resistant properties. The steel used in H-beams is typically coated with protective finishes, such as galvanization or epoxy coatings, which prevent rust and corrosion. This ensures the structural integrity of the beams, even in environments prone to moisture or humidity.

- Q: Can steel H-beams be used in the construction of residential towers or skyscrapers?

- Yes, steel H-beams can be and are commonly used in the construction of residential towers and skyscrapers. These beams provide structural support and are known for their strength, durability, and ability to withstand heavy loads.

- Q: What is the difference between hot-rolled and cold-formed steel H-beams?

- H-beams made of steel can be produced using two different methods: hot-rolling and cold-forming. These methods result in H-shaped cross-section beams that have distinct characteristics. Hot-rolled steel H-beams are created by heating a large steel billet or ingot to extremely high temperatures and then shaping it through rolling. This process involves intense heat, making the steel more malleable and easier to shape. As a result, the finished product has a rougher surface texture. Hot-rolled H-beams typically have wider flanges and thicker webs compared to cold-formed H-beams. They are commonly used in heavy-duty construction projects that require high strength and load-bearing capacity. On the other hand, cold-formed steel H-beams are manufactured by shaping cold-rolled or galvanized steel coils into the desired H-shaped profile. This process takes place at room temperature, without the use of heat. Cold-formed H-beams have a smoother surface finish and more precise dimensions compared to hot-rolled beams. They also tend to have thinner flanges and webs, making them lighter and more suitable for applications where weight reduction is important. Cold-formed H-beams are commonly used in light to medium-duty construction, such as residential buildings and infrastructure projects. In terms of mechanical properties, hot-rolled H-beams generally have higher yield and tensile strength compared to cold-formed H-beams. This is because the intense heat during the hot-rolling process allows the steel to undergo grain refinement and achieve better mechanical properties. On the other hand, cold-formed H-beams usually have lower strength but higher ductility and toughness. They can deform more before failure, making them more resistant to bending and deformation. In summary, the main differences between hot-rolled and cold-formed steel H-beams lie in the production process, surface finish, dimensions, and mechanical properties. Hot-rolled beams are produced at high temperatures, have a rougher surface, and are used in heavy-duty construction. Cold-formed beams are manufactured at room temperature, have a smoother surface, and are suitable for lighter construction applications.

- Q: How do steel H-beams contribute to natural ventilation in buildings?

- Steel H-beams play a significant role in enhancing natural ventilation in buildings. They contribute to natural ventilation by providing structural support for large openings such as windows, doors, and skylights, which allow the free flow of air into and out of the building. The H-beams are typically used in the construction of building frames, where they form the main structural elements that support the weight of the building. Their design allows for the creation of wide-span openings, which can be strategically positioned to maximize airflow and ventilation. By incorporating these large openings into the building's design, steel H-beams facilitate the intake of fresh air from the outside. This fresh air then displaces the stale indoor air, creating a natural circulation that helps maintain a healthy and comfortable indoor environment. Moreover, steel H-beams can be used to support various ventilation systems such as louvers, vents, and exhaust fans. These systems can be integrated into the openings created by the H-beams to further enhance the flow of air and improve natural ventilation. Another way steel H-beams contribute to natural ventilation is by allowing for the installation of shading devices such as sunshades or awnings. These devices can be attached to the H-beams, providing shade from direct sunlight while still allowing air to pass through. This helps to reduce solar heat gain and maintain a comfortable indoor temperature without relying heavily on mechanical cooling systems. In summary, steel H-beams contribute to natural ventilation in buildings by providing structural support for large openings, facilitating the intake and circulation of fresh air, accommodating various ventilation systems, and allowing for the installation of shading devices. These features help to improve indoor air quality, reduce energy consumption, and create a more sustainable and comfortable built environment.

Send your message to us

GB Standard Steel H Beam 294mm-346mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords