GB Standard Steel H Beam 200*200*8.0mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 200*200*8.0mm with Good Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 200*200*8.0 | 49.9 | 250*125*6.0 | 29.0 |

| 248*124*5.0 | 25.1 | 244*175*7.0 | 43.6 |

Usage & Applications of GB Standard Steel H Beam 200*200*8.0mm with Good Quality For Sale:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Production flow of GB Standard Steel H Beam 200*200*8.0mm with Good Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

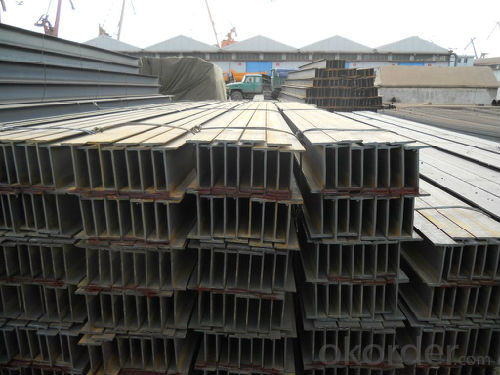

Images of GB Standard Steel H Beam 200*200*8.0mm with Good Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Why is it that the steel pile is low in cost and easy to construct, and it can be changed when there is an obstacle

- The H steel has wide flange, large lateral rigidity and strong bending resistance. It is about 5 to 10% of that of I-beam, and the flange two surfaces are parallel to each other, so the structure is convenient.

- Q: Does the cross section of corrugated steel H have this section in PKPM?

- H type steel corrugated webs, by corrugated webs and the upper and lower flange, flange and bottom flange plate in parallel or at some angle, corrugated webs perpendicular to the flange between the side fillet weld may be double fillet, depending on the corrugated web thickness and welding process decision

- Q: 300 * 150 * 6.5 * 9 H steel is used as steel beam, span 6 meters, spacing 2 meters, laying steel plate, 15 cm soil

- Q235 hot rolled H steel 300 x 150 x 6.5 x 9, weight per meter of 0.373KN. Wx=490000mm fand. Section modulus flexural strength design value of 215N/mm -. Uniform basic combination of load value Q, span 6m, the maximum bending moment design value of M=490000 * 215 =105350000N - M 105.35KN - m, q=105.35 * 8/6 L = 23.41KN/m.

- Q: Can Steel H-Beams be used in foundation or basement construction?

- Yes, steel H-beams can be used in foundation or basement construction. These beams are commonly used to provide structural support and stability to the foundation or basement walls. They offer high strength and durability, making them suitable for withstanding heavy loads and ensuring the structural integrity of the building.

- Q: Are steel H-beams resistant to UV radiation?

- Steel H-beams are not inherently resistant to UV radiation. Steel is a material that can be susceptible to corrosion and deterioration when exposed to UV radiation over an extended period of time. However, there are various methods to protect steel H-beams from UV radiation, such as applying a protective coating or using weather-resistant materials during the manufacturing process. These measures can help to enhance the durability and longevity of steel H-beams when exposed to UV radiation. It is important to consider the specific application and environmental conditions in order to determine the most suitable approach for protecting steel H-beams from UV radiation.

- Q: What are the considerations for designing with steel H-beams?

- When designing with steel H-beams, there are several considerations to keep in mind. Firstly, it is important to consider the structural requirements and load capacity of the H-beams. This includes understanding the expected loads and forces that the beams will bear, as well as the span and spacing requirements. Secondly, the dimensions and properties of the H-beams must be carefully chosen to ensure they meet the design specifications. This involves considering the beam's depth, width, and thickness, as well as the material grade. Additionally, the connection details between the H-beams and other structural elements need to be carefully designed to ensure proper load transfer and structural integrity. This includes selecting appropriate fasteners and welding techniques, as well as providing adequate bracing and reinforcement. Furthermore, factors such as fire resistance, corrosion protection, and seismic design considerations should also be taken into account when designing with steel H-beams. Overall, designing with steel H-beams requires a thorough understanding of structural engineering principles, material properties, and design codes to ensure a safe and efficient structure.

- Q: Can steel H-beams be used for supporting industrial silos or storage tanks?

- Yes, steel H-beams can be used for supporting industrial silos or storage tanks. Steel H-beams are commonly used in construction and engineering projects due to their high strength and durability. They provide excellent structural support and can withstand heavy loads, making them suitable for supporting large and heavy structures like industrial silos or storage tanks. H-beams can be easily welded or bolted together to create a strong and stable support system, ensuring the stability and safety of the silos or tanks. Additionally, steel H-beams have the advantage of being resistant to corrosion, which is important in industrial environments where the storage of chemicals or other corrosive materials may occur. Overall, steel H-beams are a reliable and cost-effective choice for supporting industrial silos or storage tanks.

- Q: How do steel H-beams perform in vibration-prone environments?

- Steel H-beams are known for their excellent performance in vibration-prone environments. The unique design of H-beams, with their wide flanges and vertical web, provides superior rigidity and strength, making them highly resistant to vibrations. This structural shape helps to distribute the load evenly, minimizing the effects of vibrations on the beam. By using steel as the material for H-beams, they offer exceptional durability and stability, which is crucial in environments where vibrations are common. Steel has a high modulus of elasticity, meaning it can withstand and absorb vibrations without undergoing significant deformation or damage. This property makes steel H-beams a reliable choice for structures exposed to dynamic loads, such as bridges, high-rise buildings, and industrial facilities. Furthermore, steel H-beams can be fabricated with additional measures to enhance their performance in vibration-prone environments. These measures include using thicker flanges, increasing the beam's depth, or incorporating damping materials. By taking these steps, the H-beams can further dampen vibrations and reduce their effect on the overall structure. In conclusion, steel H-beams are well-suited for vibration-prone environments due to their inherent strength, rigidity, and durability. Their unique design and properties enable them to withstand vibrations without compromising the structure's stability. When properly designed and executed, steel H-beams provide a reliable and efficient solution for structures that need to perform well in such challenging conditions.

- Q: Are steel H-beams suitable for rooftop structures?

- Steel H-beams are indeed suitable for rooftop structures. Their strength and durability make them an excellent option for bearing heavy loads on rooftops. They can easily support various rooftop structures like solar panels, HVAC systems, and equipment. Moreover, steel H-beams offer exceptional structural support, guaranteeing the stability and safety of the rooftop structure. Furthermore, they possess corrosion resistance and a longer lifespan compared to alternative materials, establishing them as a dependable choice for rooftop applications.

- Q: Are steel H-beams suitable for structures with complex geometries?

- Steel H-beams are commonly used in construction due to their high strength-to-weight ratio and versatility. However, when it comes to structures with complex geometries, their suitability may depend on various factors. Firstly, steel H-beams are typically produced in standard sizes and shapes, which may not be ideal for structures with irregular or intricate geometries. In such cases, custom fabrication or additional structural elements might be required to adapt the H-beams to the complex geometry, which can increase costs and complicate the construction process. Secondly, steel H-beams are most effective in structures that require long-span support or need to withstand heavy loads. Their inherent strength and rigidity make them suitable for structures like bridges, warehouses, and high-rise buildings. However, for structures with complex geometries that do not necessarily require long-span support or heavy load-bearing capacity, alternative construction materials or structural systems might be more appropriate. That being said, steel H-beams can still be used in structures with complex geometries, especially when combined with other structural components or advanced engineering techniques. By incorporating additional beams, trusses, or bracing, it is possible to distribute loads more evenly and enhance the structural integrity of the complex geometry. In conclusion, while steel H-beams are a versatile choice for many construction projects, their suitability for structures with complex geometries may depend on the specific requirements and design constraints. Consulting with structural engineers and architects is crucial to determine the best approach and select the most suitable materials for such projects.

Send your message to us

GB Standard Steel H Beam 200*200*8.0mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches