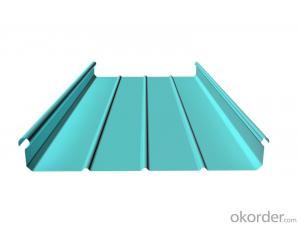

GAVANIZED RIB MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GAVANIZED Rib Lath is widely used as plaster backing on ceilings, walls and stud partitions. Rib Lath is also ideal for refurbishing damaged or aged masonry walls when a key for rendering is not certain due to disintegration or softening of the wall face.

1.Material:Hot-dipped galvanized sheet

2.Application:

1).Construction formwork mesh has very good engineering quality and construction security;

2).Construction formwork mesh as the concrete permanent assembly

free sheet is much convenient for engineering design and processing;

3).Construction formwork mesh is widely used in tunnels,bridges and valve system and so on

to make the process of construction much more fast and stable.

ZINC COATING: G30 WEIGHT: 4.5KG/SHEET

- Q: What are the different surface finishes available for steel sheets?

- There are several different surface finishes available for steel sheets, including mill finish, hot-rolled pickled and oiled, cold-rolled, galvanized, and coated finishes such as zinc, paint, or epoxy. Each finish offers unique properties and appearances, catering to different applications and requirements.

- Q: Are steel sheets suitable for oil and gas industry applications?

- Yes, steel sheets are suitable for oil and gas industry applications. Steel sheets offer excellent strength, durability, and corrosion resistance, making them ideal for various applications in the oil and gas industry, such as storage tanks, pipelines, and offshore platforms. Additionally, steel sheets can withstand high temperatures and extreme conditions, making them a reliable choice for this industry.

- Q: Q235 is hot rolled steel or cold rolled steel?

- Q235 hot rolling and cold rolling are available, depending on availabilityThe need for heating the material before hot rolling, rolling process or rolling, usually heated to above the recrystallization temperature, such as more than 1000 degrees; cold rolling is the process does not require heating of the material, or the material is heated to the temperature below the recrystallization.

- Q: Can steel sheets be used for heat transfer applications?

- Yes, steel sheets can be used for heat transfer applications due to their high thermal conductivity and ability to withstand high temperatures. They are commonly used in various industries, such as HVAC systems, automotive manufacturing, and power generation, for efficient heat transfer and dissipation.

- Q: How are steel sheets tested for quality and performance?

- Steel sheets are tested for quality and performance through a series of rigorous tests, such as tensile strength testing, hardness testing, dimensional accuracy inspection, surface finish examination, and corrosion resistance evaluation. These tests ensure that the steel sheets meet the required standards, specifications, and performance expectations, ensuring their durability and suitability for various applications.

- Q: Can the steel sheets be easily engraved or etched?

- Yes, steel sheets can be easily engraved or etched using various techniques such as laser engraving or chemical etching.

- Q: What is the average yield strength of steel sheets?

- The average yield strength of steel sheets varies depending on the specific grade and thickness of the steel. However, it typically ranges from 250 to 400 megapascals (MPa).

- Q: What is the process of embossing on steel sheets?

- The process of embossing on steel sheets involves creating raised or recessed designs on the surface of the steel by applying pressure with specialized tools or dies. This is typically done through a combination of heat and pressure, which allows the metal to be deformed and take on the desired pattern or texture.

- Q: What are the common widths of steel sheets?

- The common widths of steel sheets typically range from 24 inches to 72 inches, with increments of 6 inches.

- Q: How do steel sheets perform in tensile strength?

- Steel sheets have high tensile strength, meaning they are able to withstand large amounts of stretching or pulling forces without breaking or deforming.

Send your message to us

GAVANIZED RIB MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords