Galvanized coil in steel material SGCC hot-dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34257 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

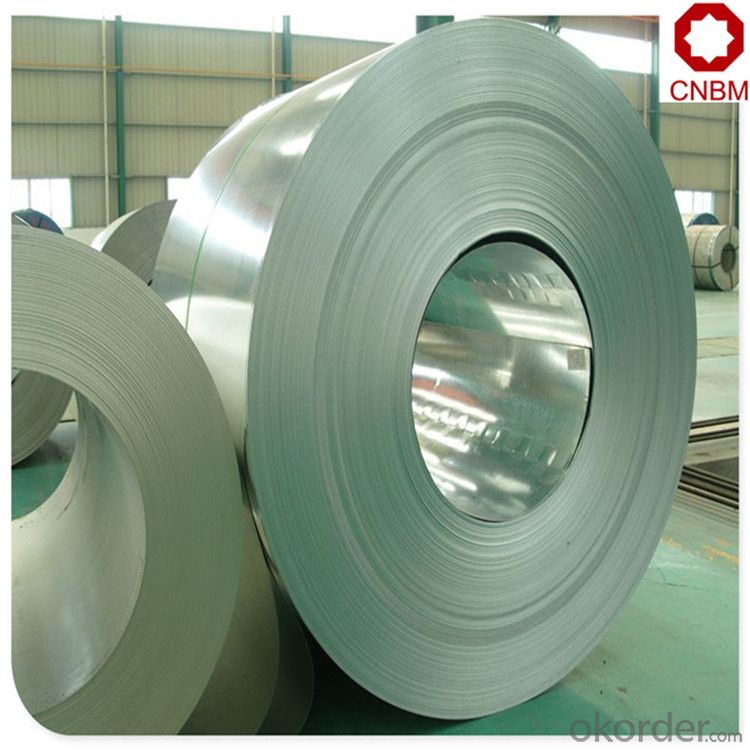

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

Certificate:

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development

- Q: In the game RuneScape, the concept of the fictitious metal, Rune has intrigued me. On an equal area AND weight basis (with a possible 10 lb exception) what metal is 256% stronger than steel?

- Depending on carbon content, alloy content and heat treatment, steel can have almost any yield strength you want it to. It can be as low as 250 MPa or as high as 1700 MPa. That's more than your 256% difference right there. So maybe the answer should be itself.

- Q: what exactly does it mean when some sword makers refer to finding the truth of steel. I have heard that many have tried to find the truth but i dont really understand what there is to find.

- I am unsure of what the Truth of Steel is, but here is the Riddle of Steel (from Conan) Thulsa Doom: Yes! You know what it is, don't you boy? Shall I tell you? It's the least I can do. Steel isn't strong, boy, flesh is stronger! Look around you. There, on the rocks; a beautiful girl. Come to me, my child... Thulsa Doom: [coaxes the girl to jump to her death] Thulsa Doom: That is strength, boy! That is power! What is steel compared to the hand that wields it? Look at the strength in your body, the desire in your heart, I gave you this! Such a waste. Contemplate this on the tree of woe. Crucify him!

- Q: How are steel coils recycled?

- Steel coils can be recycled through a process that involves melting them down in a furnace, removing impurities, and then shaping the molten steel into new coils or other steel products. This recycling method helps conserve resources, reduce waste, and significantly cut down on energy consumption compared to producing steel from raw materials.

- Q: Do any tour players use steel shafted woods? And are there any real advantages to having steel shafted woods? I have only played with one person to use steel shafted woods, he tells me thats because he cant hit it straight with graphite, however he is a very short hitter.

- Graphite shafts are generally better for the amateur golfer. Graphite shafts are more forgiving than stell shafts. With graphite shafts, it is easier to get the ball in the air, and keep your ball trajectory always with good height. For SOME above average golfers and tour professionals, steel shafted woods find their way into their bags. This is because steel shafts have the ability of being more precise in terms of direction. However, to hit steel shafted woods, you need a lot of power and a slightly faster than normal tempo. Point is, if your a golfer that plays this sport for the leisure, or don't want to be stressed, take the graphite shafts. But if you're a single-digit handicapper, and feel you're physically fit ALL THE TIME, then go ahead and try the steel shafts.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts by being uncoiled and then fed into a machine that cuts and forms the bolts. The coils provide a continuous supply of high-quality steel, ensuring consistent and precise production of bolts.

- Q: How are steel coils used in the production of metal buildings?

- Steel coils are used in the production of metal buildings as they are rolled into sheets and then formed into various structural components such as beams, columns, and roof panels. These coils allow for efficient mass production and provide a high-strength and durable material that ensures the structural integrity of the metal building.

- Q: I really need help what is the origon of stainless steel?

- In metallurgy, stainless steel, also known as inox steel or inox from French inoxydable, is a steel alloy with a minimum of 10.5% chromium content by mass.

- Q: Can steel coils be painted or coated?

- Yes, steel coils can be painted or coated. Painting or coating steel coils is a common practice to enhance their aesthetic appeal, protect against corrosion, and improve durability.

- Q: What are the common applications of cold-rolled stainless steel coils?

- Cold-rolled stainless steel coils are widely used in various industries due to their unique characteristics and versatility. Some common applications of these coils include: 1. Automotive Industry: Cold-rolled stainless steel coils are used in the automotive industry for manufacturing parts such as exhaust systems, trim, and body panels. The high corrosion resistance and aesthetic appeal of stainless steel make it an ideal choice for these applications. 2. Construction Industry: Stainless steel coils are extensively used in the construction industry for roofing, cladding, and structural components. The durability, strength, and resistance to corrosion make cold-rolled stainless steel coils a preferred material in buildings, bridges, and other infrastructure projects. 3. Kitchen Appliances: Stainless steel coils are commonly used in the production of kitchen appliances such as refrigerators, ovens, and dishwashers. The hygienic properties, easy maintenance, and sleek appearance of stainless steel make it a popular choice for these applications. 4. Food Processing Industry: Cold-rolled stainless steel coils find extensive use in the food processing industry due to their non-reactive nature and resistance to corrosion. These coils are used for manufacturing equipment, storage tanks, and conveyor systems in food processing plants. 5. Medical Equipment: Stainless steel coils are widely used in the medical industry for manufacturing surgical instruments, implants, and medical devices. The biocompatibility, strength, and resistance to corrosion of stainless steel make it suitable for these critical applications. 6. Oil and Gas Industry: Cold-rolled stainless steel coils are used in the oil and gas industry for various applications, including pipelines, storage tanks, and offshore platforms. The high resistance to corrosion and extreme temperature conditions make stainless steel a reliable choice in this demanding industry. 7. Aerospace Industry: Stainless steel coils are employed in the aerospace industry for manufacturing aircraft components, engine parts, and structural elements. The lightweight yet high-strength properties of stainless steel make it an ideal material for these applications. Overall, the common applications of cold-rolled stainless steel coils span across diverse industries, including automotive, construction, kitchen appliances, food processing, medical, oil and gas, and aerospace. The unique combination of durability, corrosion resistance, strength, and aesthetic appeal make stainless steel coils a preferred choice in various industrial sectors.

- Q: What are the weight ranges for steel coils?

- The weight ranges for steel coils can vary depending on the specific type and size, but they typically range from a few hundred kilograms to several metric tons.

Send your message to us

Galvanized coil in steel material SGCC hot-dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34257 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords