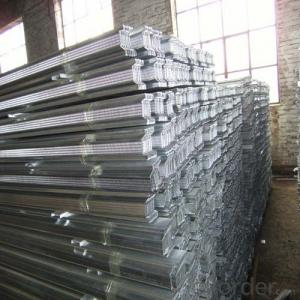

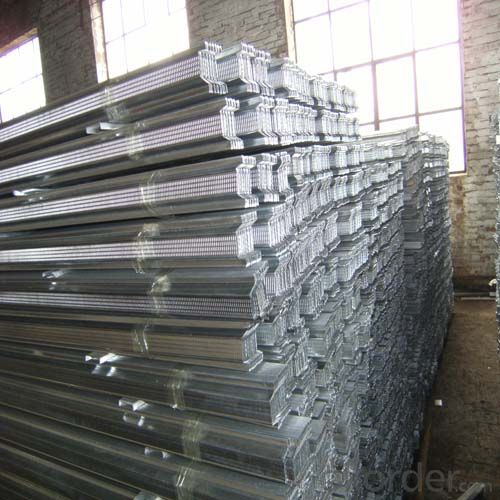

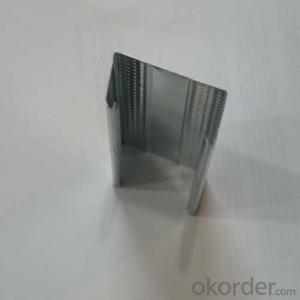

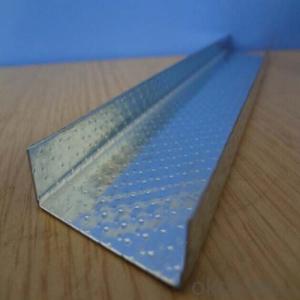

Galvanized Steel Material Furring Channel For Drywall Ceiling Grid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

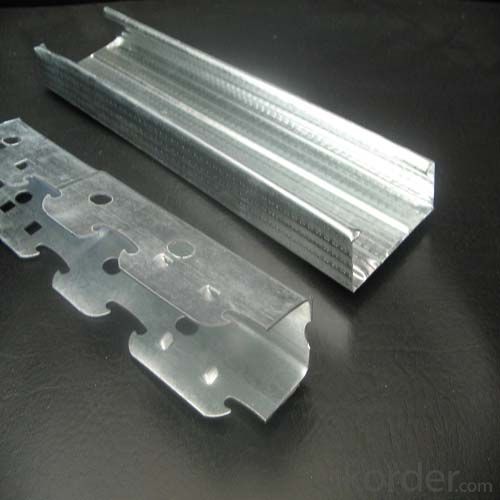

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

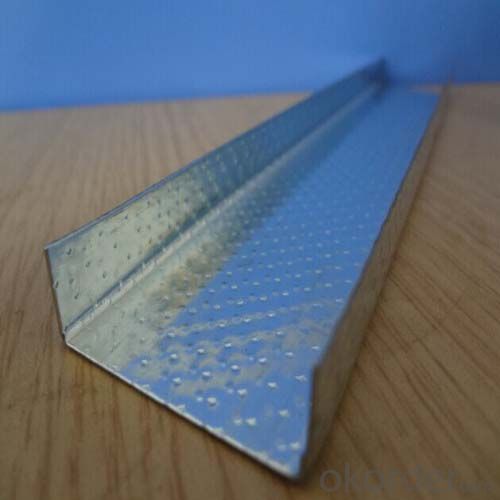

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Drywall section metal profile

1. Usage: gypsum board drywall

2.Easy to install

3.High strength

4.Size exact, easy cut

Metal steel profile stud and track light steel keel for drywall system

Product Overviews

Product characteristic

1) High quality of raw material with hot dipped Galvanized steel coil

2) Easy to operate and solid after installation

3) Durable for at least 10 years life-span

4) Moisture proof, Rust resistance

5) Many difference size. Export to different market

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- The room to remove the partition, you can retain the original light steel keel gypsum board ceiling.

- Q: Home to decorate the ceiling, playing the wall, I learned from the market can be resistant, dragon card, Saint Gobanchenko these brands of light steel keel gypsum board which good point?

- You said these are very good brand, Saint-Gobain and Long card companies with more. The material is on the one hand, the ceiling is the most important woodworking craft and craftsmanship. Material is not a problem

- Q: Can my light steel keel ceiling withstand the weight?

- Light steel keel with superior and non-superior type. 50 light steel keel is not on the man's 50mm * 19mm * 0.5mm man's 50mm * 20mm * 0.6mm main keel man 60 * 27 * 1.2. In addition, the keel of the outer keel does not require less than 600 * 600, and the mandarin keel is usually not less than 400 * 400 according to the load. Compare your material to see what specifications the keel is. Baidu may wish to look at these two types. If it is superior type, there is no problem

- Q: How to remove the gypsum board cut off

- Partition may be a metal structure, can not be sparks in the environment, can not use cutting machine, can not use metal hit metal. Can not use the fire.

- Q: How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- First with the expansion bolts fixed heaven and earth keel and roof and the ground, the middle with a vertical keel; if the layer is too high, then the keel will have joints, of course, have special connections.

- Q: Light steel keel partition wall construction process is what

- Processes: Bracket, Divider Pillow Pillow (Design Required) Fixed along the top, along the keel fixed Bone keel installation Vertical keel installation door, window frame installation Additional keel installation Support keel, check keel installation Electrical pipe , Installation of the installation of the wall equipment, a cover panel filled with sound insulation material installation, the other side of the panel panels and corners of the treatment of quality inspection.

- Q: In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- First do a good wall partition 2.8 high, 6 meters high in the top if it is the roof, then use the boom directly pull down

- Q: Light steel keel wall how much money a square

- Steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, construction is simple Deformation and other advantages.

- Q: 100 light steel keel 9.5mm thick gypsum board double double-sided partition three times, three times latex paint.

- Light steel keel a 3 meters, just the height of the wall is 3m, vertical wall keel is not a waste of material.

- Q: With light steel keel gypsum board do partition wall price how to count?

- Baoqing about 25, all 100-130 (material pricing).

Send your message to us

Galvanized Steel Material Furring Channel For Drywall Ceiling Grid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords