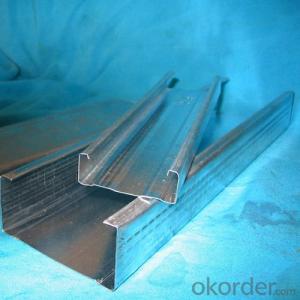

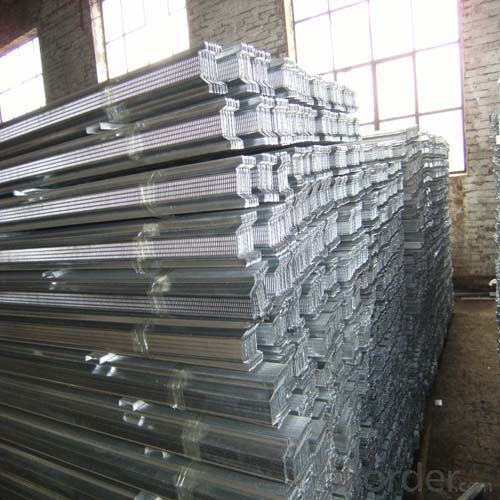

Galvanized Steel Drywall Runner and Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name: Galvanized steel profile/metal stud/drywall stud

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Galvanized steel profileTechnicology:

1.adopting high-grade quality hot-dipped galvanized steel,

2.The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common product.

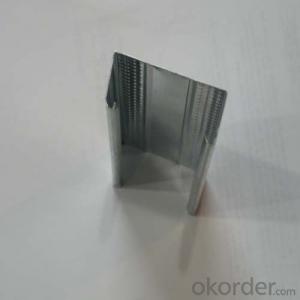

Steel stud

Made from hot dipped galvanized steel strip

Partition wall of steel structure buildings

GB/T3381.1-93

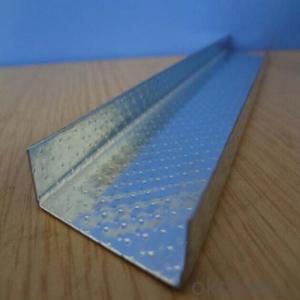

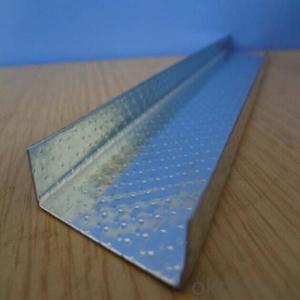

Features of steel stud

1, advanced equipment, production technology, advanced detection methods of science, the product surface, rolling, high precision, beautiful shape, straight;

2,Using the high quality continuous hot-dip galvanizing cold-rolled coil for the base material ,material evenly ,moderate hardness , light weight ,fireproof, combination convenience , Not subject to seasonal effects, the construction simple and quick, greatly shortening the duration and improve the working efficiency;

3, the steel stud have good corrosion resistance ability, long service life;

4, Cross-section structure is reasonable, humane design: Keel, Vice keel and vertical played pitting self-tapping screw designed to effectively prevent sideslip, improve the construction speed, Vice-keel edge of the stiffener designed to enhance the steel keel, anti-subsidence more capable, the level of vertical keel edge design makes perfect fastening, an increase of product application design

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures:

- Q: In Shanghai 75 partition wall light steel keel 0.6 what price now

- Low-grade 3.5-4.5 yuan / m range. Light steel keel, flower head a lot. Side high, the actual thickness, galvanized surface, strip material are very affected price.

- Q: Now what is the room wall material is fashionable? Environmentally friendly

- Sound insulation cotton how to be environmentally friendly too old and toxic The best material is lightweight partition wall insulation insulation and non-toxic light foam cement board wallboard calcium silicate partition board and keel plus paint-free green frog Non-toxic dalfers are currently my best found some non-toxic

- Q: The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- Can only use the exhibition frame. You may be a mall. Now shopping malls are so, independent to be a exhibition,

- Q: To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With C-beam or two angle steel, LI put two and wall fixed, the keel fixed to the LI. Do not be able to drill on the ground.

- Q: Home improvement in the partition

- Light steel keel, wood keel wall: light steel keel is a substitute for wood keel products, fire effect is significant (when using wood keel to brush fire retardant coating). As a partition wall of the external use of the plate there are gypsum board, Ed panels and aluminum-plastic panels, according to the actual requirements. If you want to do noise effects, in the middle of the installation of rock wool or mineral wool sound-absorbing panels;

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Can be light steel keel wall itself is not heavy weight

- Q: Light steel keel wall can be installed sliding door

- 940 door to install the sliding door a bit small, open only less than 500 after the space, I suggest you install the folding door

- Q: Light steel keel with what screws fixed gypsum board

- That is, depending on the general distance from the general self-tapping screw teeth to be larger. Fast teeth screws are generally used for wood, aluminum and other materials, in the role of power tools, you can quickly into the material inside their own. Because the fast tooth screws are mostly self-attack class, will not use the nut. Ordinary screw general mechanical screws, can support the nut. ??? Mechanical screws and self-tapping screws are very different in tooth pitch.

- Q: Light steel keel partition wall door how to do

- The wall keel to use the national standard light steel wall keel - the thickness of the strength of only;

- Q: Light steel keel partitions and finished partitions

- Light steel: the frame and the outer panel should be in the construction site processing, but also brush at least 2 times the putty +2 paint. Finished partition: mainly in the factory processing, in the field just assembled only.

Send your message to us

Galvanized Steel Drywall Runner and Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords