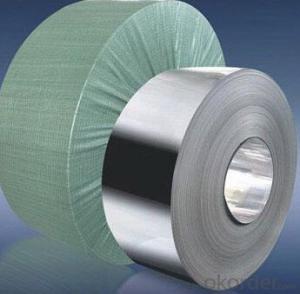

Galvanized steel coil in low price DX51D+Z

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

Standard and Grade :

Hot-dip galvanized steel coils | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: How are steel coils used in the production of food processing machinery?

- Steel coils are used in the production of food processing machinery to construct various components such as frames, supports, and structural elements. These coils are typically shaped, cut, and welded to create the required parts, ensuring durability and strength in the machinery.

- Q: For some reason, if you rub iron oxide or lodestone (both very crumbly, dark, mineral-like materials) into soft, unhardened steel, their particles actually get stuck into the surface of the steel (that is, darkening it). My question is, how does this work? How come iron oxide and lodestone can get stuck, and how come other materials (like silicone carbide, for example) do not?My second question is, are there any materials that can get stuck into steel, that is also blue in color, and how would I best obtain it?

- If you look at the surface of untreated steel even with a low power microscope you will see a surface that is far from smooth, there are pits and occlusions dotting the surface. Steel is not polished when you see it this way so the only treatment to the surface was the extrusion process or forming done on it by the presses. Iron oxide has a very small particle size and when pulverized into a powder it can easily fill the pits and voids in the steel surface coloring it.

- Q: I have a new stainless steel trash compactor under a butcher block counter. We refinished the countertop, but unfortunately the person who did it wasn't careful with the orbital sander and sanded the top edge of the stainless steel compactor door, ruining the finish. The sander marks are not deep - just surface scratches - but they are unsightly. Is there any way to restore the finish to the stainless steel without having to buy a new door?

- This Site Might Help You. RE: How to refinish stainless steel appliance? I have a new stainless steel trash compactor under a butcher block counter. We refinished the countertop, but unfortunately the person who did it wasn't careful with the orbital sander and sanded the top edge of the stainless steel compactor door, ruining the finish. The sander marks are not...

- Q: Can steel coils be transported by air?

- Yes, steel coils can be transported by air.

- Q: I am working on a hydrogen generator, but the stainless steel I am using corrodes and turns the water brown. Can anyone tell me if there is stainless steel that does not corrode, and if so, what is it called and where can I get some.Thank you.

- All stainless steel will corrode in certain conditions. Some varieties are worse than others. For instance grade 409 which is used for car exhausts (and other things) will rust. For the most suitable grade call a local steel supplier which carries stainless steel. Some of these companies will have a catalog of available grades and the appropriate uses. It would probably help to let them know what types of chemicals are present and what temperature the water is. You may want to call several suppliers, the quality of answer you get may vary quite a bit from company to company. The cost of exotic grades of stainless can be quite high. you may have to use a less appropriate grade if you can't justify the cost. If corrosion is a very serious concern for this be forewarned that stainless steels can be contaminated by contact with carbon steel (ordinary steel). I have seen rust form on stainless steel after a carbon steel bar was set down on the stainless steel. The carbon steel will leave trace amounts under prolonged contact. I have even seen signs of contamination of stainless steel direct from the supplier.

- Q: Two different shaving razors I'm looking to buy have different specs. in terms of the metals used for the blade; one being 1045 surgical stainless steel, the other 440 stainless (not sure if its A B or C, but probably 440A or 440B because it's not specified). So which one is better for the intended use as a shaving razor?

- Type 440 combines such a high grade of cutlery steel, toughness and economy that it is actually known as razor blade steel. Browsing around (a lot) more, it seems that 1045 Surgical Steel is popular in straight razors used by barbers. These razors are honed by stropping with leather and last practically forever. From the above, I would guess that it might be easier to lose the edge on 1045, but also easier to re-sharpen it, that it won't easily knick because probably not so hard as 440. I'm not sure if it would be more expensive, unless it has a superior handle etc. So, I would expect to spend a little more effort over the lifetime of the 1045, maybe pay a little more for it, but have a longer lifetime. hth.

- Q: I do a lot of scrapping and would like to be able to separate stainless steel from regular steel. The magnet test doesn't always work since stainless can be magnetic, but what are some ways that I can for sure tell the difference? Or even something like a sound that they make that may help me to tell the difference.

- Stainless steel uses chromium in its mixture to thwart the affects of corrosion. General steel, or carbon steel, is generally almost completely iron and is used for far greater applications than stainless steel. Stainless steel is used mostly in kitchen appliances, utensils, etc... The best thing I can come up with is to find a way to measure the chromium content of the steel you are looking at. If it's around 3% chromium, it's probably standard steel. If it's somewhere between 10-15% chromium it's probably stainless steel (or even 4% plus). I can't tell you a fast and quick way to test the steel because from my research, it appears there are as many grades and allows of steel as there are uses for steel! There is one test I've seen for home testing surgical steel which is a higher grade stainless steel, that is to put scotch tape on one section of material then soak it in water for a 24 hour period, then let it air dry for 24 hours. You remove the tape and lightly polish the exposed areas to see if there was any discoloration or pitting on the exposed area. This test is mainly for surgical steel jewelry, however stainless steel is supposed to resist rusting more than standard steel, hence it might work for other steel types as well. You may have to read some of the other links below to get some other ideas on how you can test steel to see if it is stainless.

- Q: How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being cut and formed into various components, such as brackets and supports. These components are then assembled and welded together to create the frame and structure of the shelving unit. The steel coils provide strength and durability to the shelving units, ensuring they can withstand heavy loads and provide long-lasting storage solutions.

- Q: Can steel coils be coated with anti-counterfeit materials?

- Yes, steel coils can be coated with anti-counterfeit materials. These materials can include specialized coatings, holograms, unique serial numbers, or other security features that help prevent counterfeiting and ensure the authenticity of the steel coils.

- Q: exactly what is the differance between strontuim steel and stainless steel any differances as far as hardness .... need help.

- Strontium steel is created by soaking a mild steel in strontium chromate, which has a pH of about 4 or 5, roughly the equivalent of acid rain. Chromate affects the cathodic reaction, with reduction of Cr6+ to Cr3+, and the surface film was composed of magnetite and hydrated chromium hydroxide. The Strontium is a radioactive isotope. The acid bath permeates the mild steel causing it to become mildly radioactive. Simular to oil imprengation of brass and other metals. Strontium Steel has a very high value of inhibition. However due to it's radioactive properties it is not a commonly used or manufactured material. As for where to actually obtain Strontium steel dowels. I have no idea i would speculate that you would have to purchase the raw stock and have it machined into a dowel for you.

Send your message to us

Galvanized steel coil in low price DX51D+Z

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords